Positive photosensitive resin composition, partition wall and optical element

A photosensitive resin and composition technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of ink white spot, ink cannot be uniformly coated, etc., and achieve excellent ink repellency, good appearance, and white spot suppression. effect of phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0336] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to these examples.

[0337] Examples 1-4 are examples, and Example 5 is a comparative example.

[0338] Each measurement was performed according to the following method.

[0339] [Number average molecular weight (Mn)]

[0340] Using a commercially available GPC measuring device (manufactured by Tosoh Corporation, device name: HLC-8320GPC), the gel of several kinds of monodisperse polystyrene polymers with different degrees of polymerization commercially available as a standard sample for molecular weight measurement was measured. Permeation chromatogram (GPC), based on the relationship between the molecular weight of polystyrene and retention time (retention time), a standard curve was prepared.

[0341] After diluting the sample with tetrahydrofuran to 1.0% by mass and passing it through a 0.5 μm filter, the GPC of the sample was measured using...

Synthetic example 1~3

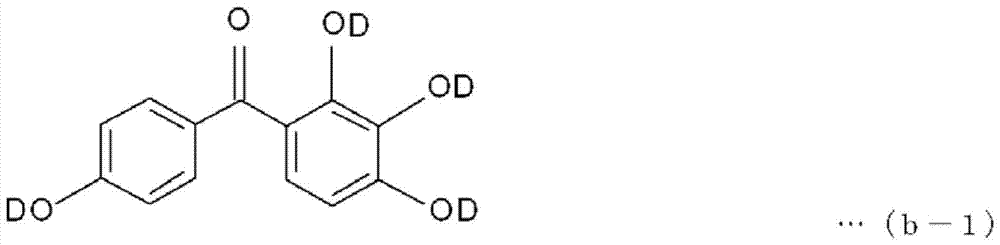

[0370] [Synthesis examples 1 to 3: Synthesis of ink repellent agents (CA1) to (CA3) and preparation of liquids (CA1-1) to (CA3-1)]

[0371] At 50cm with the mixer 3 0.57 g of the above-mentioned compound (c-11), 1.27 g of the above-mentioned compound (c-21), and 0.74 g of the above-mentioned compound (c-31) were charged into a three-necked flask of a , and a raw material mixture of the ink repellent agent (C1) was obtained. Next, 9.85 g of PGME was thrown into this raw material mixture to prepare a solution (raw material solution).

[0372] At room temperature, 1.33 g of 1.0 mass % phosphoric acid aqueous solution was dripped at the obtained raw material solution as a catalyst, stirring. After completion|finish of dripping, it stirred for 5 more hours, hydrolysis and partial condensation reaction were performed, and (CA1-1) liquid which was the PGME solution containing ink repellent agent (CA1) by 10 mass % was obtained.

[0373] Except having used 1.33 g of raw materials sh...

Synthetic example 4

[0374] [Synthesis example 4: Synthesis of ink repellent agent (CA4) and preparation of (CA4-1) liquid]

[0375] Except having used the said compound (c-32) instead of the said compound (c-31), it carried out similarly to the synthesis example 1, and prepared the raw material solution of the ink repellent agent (CA4).

[0376] 0.93 g of 1.0 mass % nitric acid aqueous solution was dripped at room temperature, stirring in the obtained raw material solution. After completion|finish of dripping, it stirred for 5 more hours, hydrolysis and partial condensation reaction were performed, and (CA4-1) liquid which was the PGME solution containing ink repellent agent (CA4) by 10 mass % was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com