Method for producing ink repellent, negative photosensitive resin composition, partition, and optical element

A technology of a photosensitive resin and a manufacturing method, which is applied in the field of optical elements, can solve the problems of reduced ink repellency of partition walls, poor ink repellency of partition wall surfaces, and poor ink affinity on the sides of partition walls, etc., achieving excellent storage stability, Effect of suppressing the void phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0526] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to these examples. In addition, Examples 1-6 and Examples 8-13 are examples, and Example 7 and Example 14 are comparative examples.

[0527] Each measurement was performed by the following method.

[0528] [Number average molecular weight (Mn)]

[0529]Using a commercially available GPC measuring device (manufactured by Tosoh Corporation, device name: HLC-8320GPC), the gels of several commercially available monodisperse polystyrene polymers with different degrees of polymerization were measured as standard samples for molecular weight measurement. Permeation chromatography (GPC), according to the relationship between the molecular weight of polystyrene and retention time (retentiontime), a standard curve was made.

[0530] After diluting the sample with tetrahydrofuran to 1.0% by mass and passing it through a 0.5 μm filter, the GPC of the sample...

example 1

[0552] [Example 1: Synthesis of ink repellent (C1) and production of (C1) liquid]

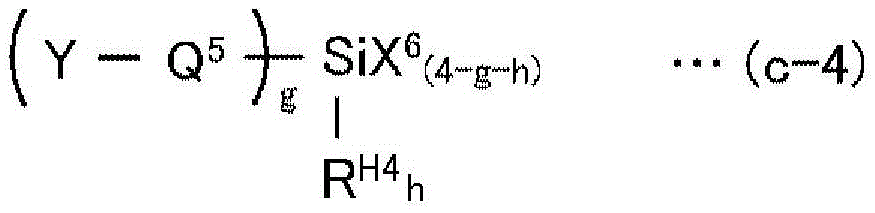

[0553] The ink repellent agent (C1) is synthesize|combined by the reaction represented by the formula (71) shown below.

[0554] It should be noted that the product obtained by the reaction shown in formula (71) is a partial hydrolysis condensate with hydrolyzable groups or silanol groups remaining. In this example, the obtained partial hydrolysis condensate is used as ink repellent. Agent (C1) is used. However, it is difficult to represent the product (partially hydrolyzed condensate) with a chemical formula. In formula (71), the average composition formula shown in formula (3-2) assumes that the product (partially hydrolyzed condensate) produced by the reaction shown in formula (71) is partially hydrolyzed The chemical formula when all the hydrolyzable groups or silanol groups in the condensate form siloxane bonds.

[0555] At 50cm with the stirrer 3 Add 0.5g compound (c-11), 0.34g compoun...

example 2

[0563] [Example 2: Synthesis of ink repellent (C2) and production of (C2) liquid]

[0564] At 50cm with the stirrer 3 0.5 g of compound (c-11), 0.41 g of compound (c-21), and 1.67 g of compound (c-31) were added to a three-necked flask to obtain a raw material mixture of an ink repellent agent (C2). Next, 9.0 g of PGME was added to this raw material mixture to prepare a solution (raw material solution).

[0565] To the obtained raw material solution, 0.16 g of a 65% by mass nitric acid aqueous solution was added dropwise while stirring at room temperature, and the compound (c-21) in the mixture, namely C 6 h 5 NH(CH 2 ) 3 Si(OCH 3 ) 3 become [C 6 h 5 NH 2 (CH 2 ) 3 Si(OCH 3 ) 3 ] + ·NO 3 - (Process (I)).

[0566] After 5 minutes, 1.44 g of 1.0 mass % nitric acid aqueous solution was further dripped. After the dropwise addition, it was further stirred for 5 hours, and the ink repellent ( C2) (step (II)). In the step (II), the reaction was monitored by gas ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com