Graphene transparent electrode and its manufacturing method and supercapacitor using it

A supercapacitor, transparent electrode technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve the effect of excellent transparency and excellent capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

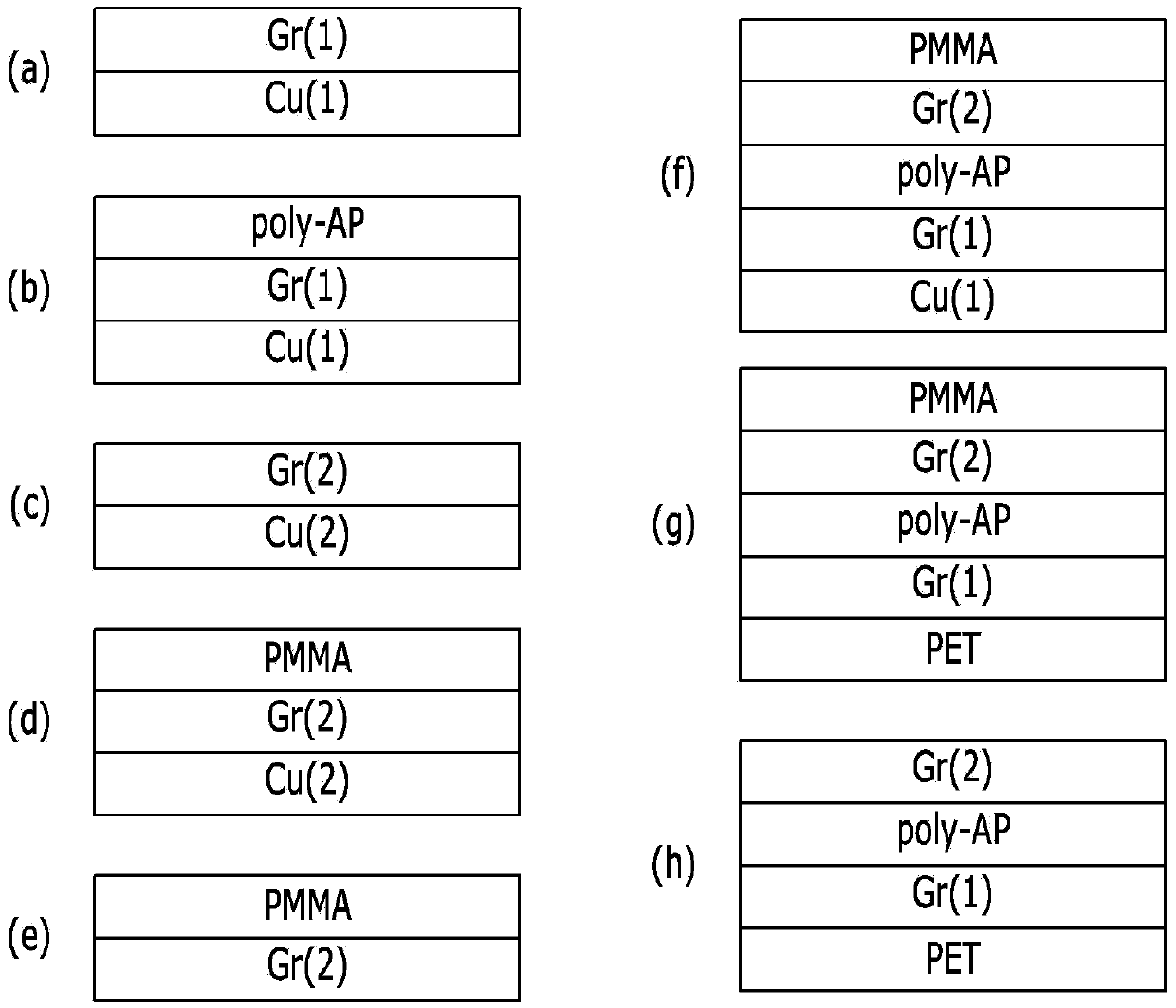

Embodiment 1

[0090] A single layer (1 layer) of a first graphene layer was formed on one side of a copper thin film with a thickness of 25 μm by chemical vapor deposition (CVD) to manufacture a first laminated structure (Cu / Gr).

[0091] At this time, argon (Ar) / hydrogen (H 2 ) mixed gas (Ar / H 2 flow = 100sccm / 50sccm) and annealing (annealing) at a temperature of 1000°C for 45 minutes, and then supplying a mixed gas of methane: hydrogen: argon in a ratio of 4sccm: 50sccm: 100sccm under the same temperature conditions for about 35 minutes to carry out graphite ene synthesis reaction. After the reaction was completed, it was rapidly cooled at room temperature (about 25° C.).

[0092] The first laminated structure is placed in a plastic petri dish (petri dish), and then poured into 1mM p-aminophenol (poly-AP) aqueous solution, and then the self-polymerization reaction of p-aminophenol is carried out on the surface of the first graphene layer for two hours to form a polymer layer.

[0093]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com