Inflatable fermented milk and preparation method thereof

A technology for fermented milk and starter, applied in dairy products, milk preparations, applications, etc., can solve problems such as unfavorable absorption, deterioration, and difficulty in maintaining product aeration and taste, and achieve extended shelf life, avoid stratification problems, and improve gas content. and the effect of gas stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

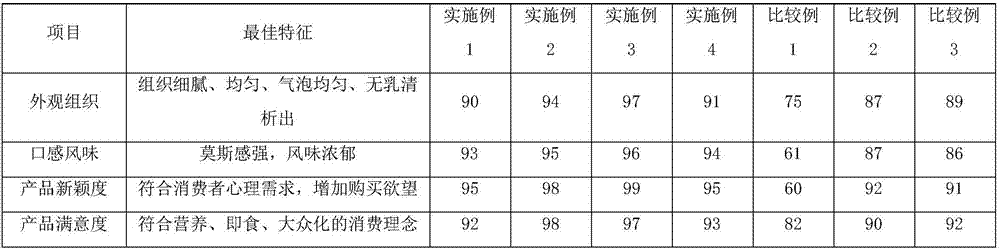

Examples

Embodiment 1

[0027] Carry out proportioning according to the embodiment 1 in table 1.

[0028] 1) Preheat raw milk to 70°C and 18MPa for homogenization; sterilize at 110°C for 300 seconds; put the sterilized material into a milk buffer tank and cool to 42°C, inoculate the starter BD-100 (including thermophilic chain Bacillus delbrueckii subsp. bulgaricus), fermented at 42°C for 6.5 hours until the acidity reached 75°T;

[0029] 2) Temporarily store aseptic tanks when the temperature drops to 25°C;

[0030] 3) Preheat the cream to 50°C, add gelatin, stir well, and sterilize at 95°C for 300 seconds; 4)

[0031] Cool the sterilized material to 50°C, put it into the above-mentioned aseptic tank, let the two materials mix evenly, and put the prepared

[0032] The prepared mixture is cooled to 6° C., and inflated by 40% through an aeration device to obtain a finished product.

Embodiment 2

[0034] Carry out proportioning according to embodiment 2 in table 1.

[0035] 1) Preheat raw milk, part of the white sugar and concentrated milk protein to 60°C, and mix well;

[0036] 2) Cool to 5°C, stop stirring, temporarily store, homogenize at 70°C and 18MPa, sterilize at 110°C for 300 seconds, put the sterilized material into a milk buffer tank and cool to 44°C, inoculate the starter BD-100 ( Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus), starter Bb-02 (including Bifidobacterium bifidum), L.casein 431 (including Lactobacillus casei), fermented at 44°C for 6 hours until the acidity reached 75° T;

[0037] 3) Temporarily store aseptic tanks when the temperature drops to 20°C;

[0038] 4) Preheat the cream to 50°C, add the remaining white sugar, gelatin and modified starch, stir well,

[0039] Sterilize at 95°C for 300 seconds;

[0040] 5) Cool the sterilized material to 55°C, put it into the above-mentioned aseptic tank, let the two materi...

Embodiment 3

[0043] Carry out proportioning according to embodiment 3 in table 1.

[0044] 1) Preheat raw milk, concentrated milk protein and part of white sugar to 60°C and mix well;

[0045]2) Cool to 10°C, stop stirring, temporarily store, homogenize at 60°C and 20MPa, sterilize at 110°C for 300 seconds, put the sterilized material into a milk buffer tank and cool to 37°C, inoculate the starter BD-100 ( Including Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus), L.casein 431 (including Lactobacillus casein), fermented at 37°C for 7.5 hours until the acidity reached 75°T;

[0046] 3) Temporarily store aseptic tanks when the temperature drops to 20°C;

[0047] 4) Preheat the cream to 50°C, add the remaining sugar, gelatin, pectin and guar gum, stir well

[0048] Evenly, sterilize at 95°C for 300 seconds;

[0049] 5) Cool the sterilized material to 55°C, pour it into the above-mentioned aseptic tank, mix the two materials evenly, cool the prepared mixture to 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com