Pure corn ice cream cone and preparation method thereof

A production method and ice cream technology, which are applied in the fields of frozen desserts, food science, and applications, can solve the problems affecting the frozen egg-cone beverage market, etc., and achieve the effects of good molding effect, high nutritional value and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

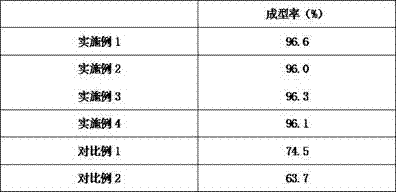

Examples

Embodiment 1

[0024] A pure corn ice cream cylinder, containing the following raw materials by weight percentage: konjac flour 4.5%, whole egg powder 5.5%, water 20%, corn balance.

[0025] The above-mentioned manufacturing method of a pure corn ice cream cylinder comprises the following steps:

[0026] A. After crushing the corn, add konjac flour, water and whole egg powder, mix evenly and repeatedly crush, and pass through a 120-mesh sieve;

[0027] B. Add the pulverized material to the twin-screw extruder, set the working temperature and the rotating speed of the extrusion screw of the twin-screw extruder cavity, and extrude the material at the template at the outlet of the twin-screw extruder; obtain corn piece;

[0028] C. Make the corn flakes into ice cream cylinders with molds.

[0029] The working temperature in the step B is 125° C., and the rotation speed of the extrusion screw is 235 rpm.

[0030] The corn flakes that described step B obtains has a moisture content of 8.5%.

...

Embodiment 2

[0034] A pure corn ice cream cylinder, containing the following raw materials by weight percentage: Contains the following raw materials by weight percentage: konjac flour 3%, whole egg powder 6%, water 18%, corn balance.

[0035] The above-mentioned manufacturing method of a pure corn ice cream cylinder comprises the following steps:

[0036] A. After crushing the corn, add konjac flour, water and whole egg powder, mix evenly and repeatedly crush, and pass through a 120-mesh sieve;

[0037] B. Add the pulverized material to the twin-screw extruder, set the working temperature and the rotating speed of the extrusion screw of the twin-screw extruder cavity, and extrude the material at the template at the outlet of the twin-screw extruder; obtain corn piece;

[0038] C. Make the corn flakes into ice cream cylinders with molds.

[0039] The working temperature in the step B is 120° C., and the rotation speed of the extrusion screw is 250 rpm.

[0040] The moisture content of t...

Embodiment 3

[0044] A pure corn ice cream cone containing the following ingredients by weight: konjac flour 5%, whole egg powder 4%, water 22%, corn balance.

[0045] The above-mentioned manufacturing method of a pure corn ice cream cylinder comprises the following steps:

[0046] A. After crushing the corn, add konjac flour, water and whole egg powder, mix evenly and repeatedly crush, and pass through a 120-mesh sieve;

[0047] B. Add the pulverized material to the twin-screw extruder, set the working temperature and the rotating speed of the extrusion screw of the twin-screw extruder cavity, and extrude the material at the template at the outlet of the twin-screw extruder; obtain corn piece;

[0048] C. Make the corn flakes into ice cream cylinders with molds.

[0049] The working temperature in the step B is 140° C., and the rotation speed of the extrusion screw is 220 rpm.

[0050] The moisture content of the cornflakes that described step B obtains is 8%.

[0051] In the step C, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com