A large-scale horizontal cutting and feeding integrated steel ball forming machine

A forming machine, horizontal technology, applied in forging presses, forging presses, shearing devices, etc., can solve the problems of unreasonable line matching, low degree of automation, low production efficiency of large forged steel balls, etc., to reduce quality accidents. probability, energy saving, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

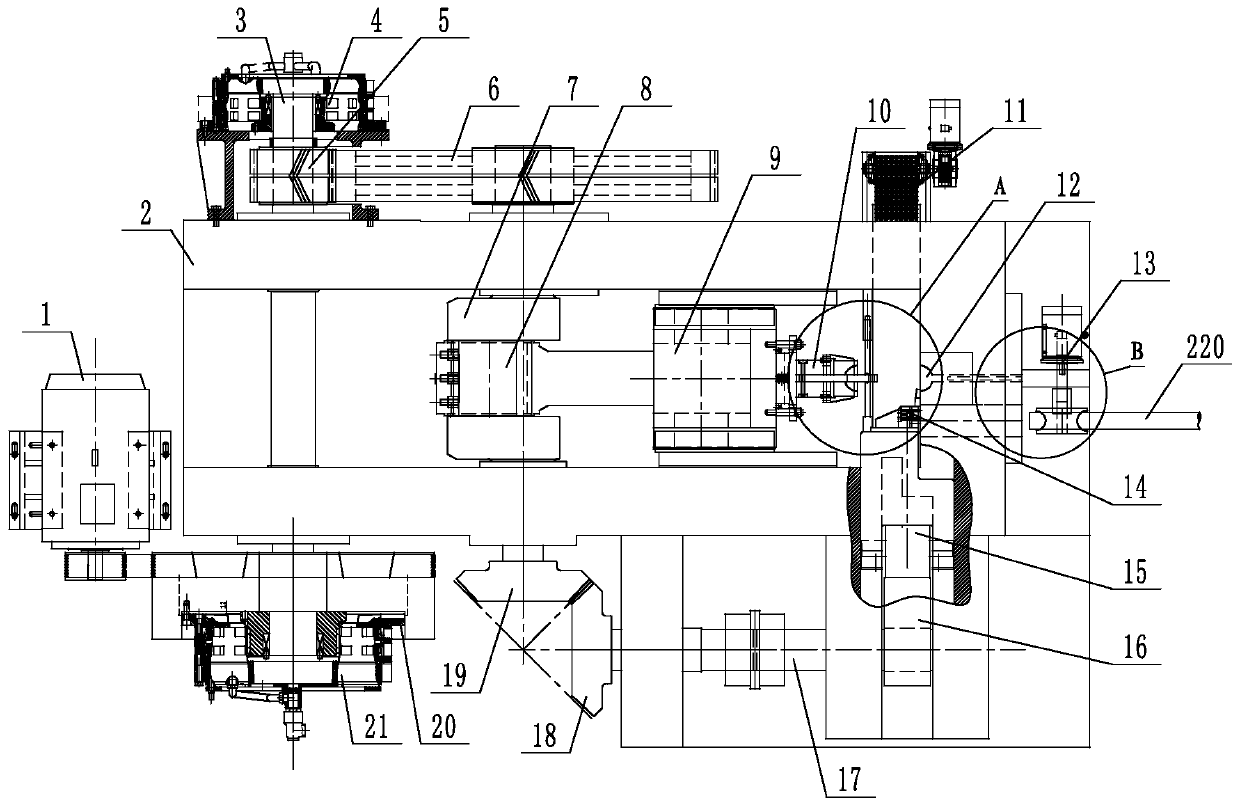

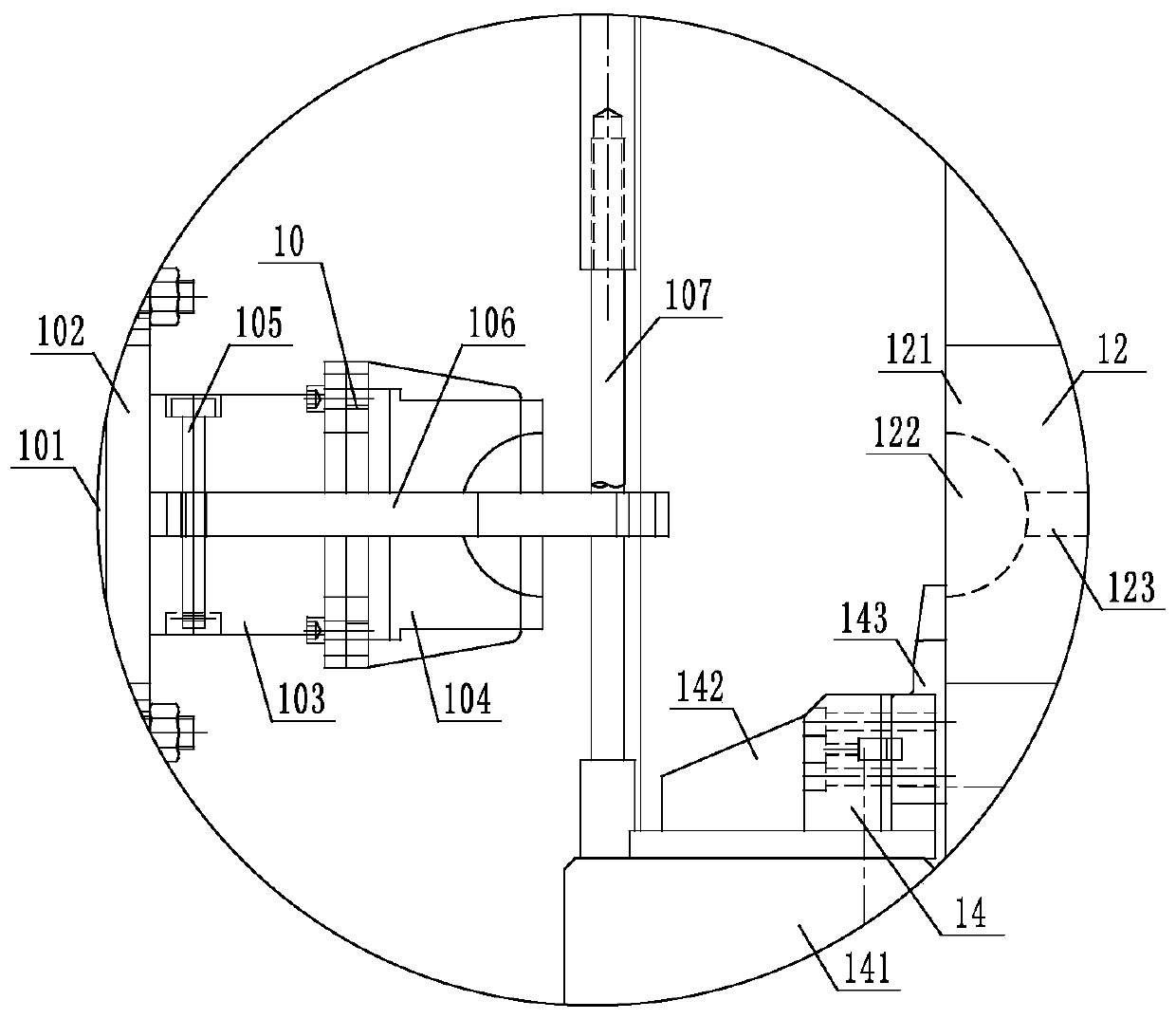

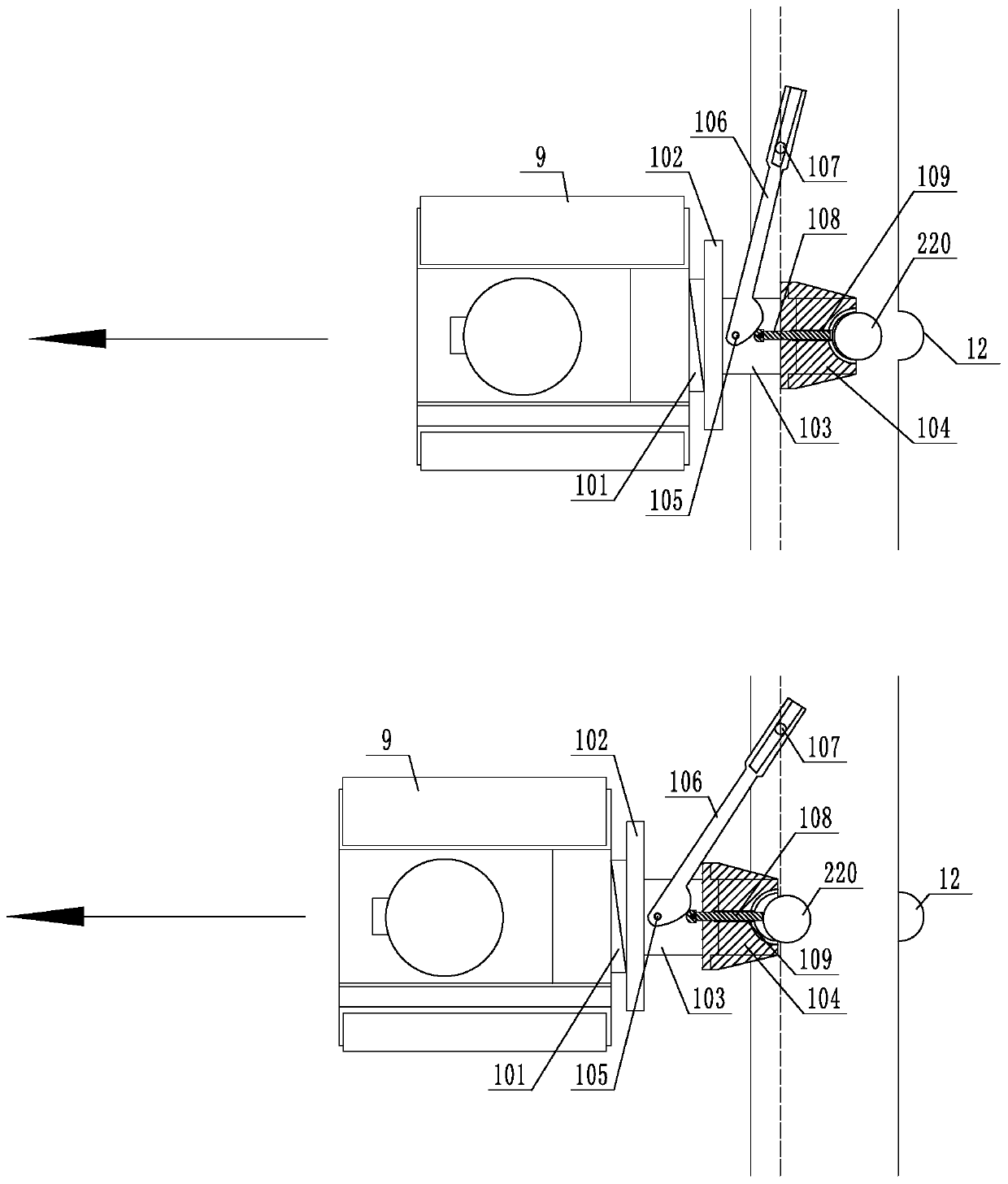

[0035] Such as Figure 1 to Figure 4 As shown, the large-scale horizontal shear-feeding integrated steel ball forming machine includes a bed 2, a transmission mechanism, a movable mold mechanism 10, a fixed mold mechanism 12, and a conveyor 11. A transmission mechanism is connected to the bed, and the transmission mechanism drives the movable mold mechanism to move. The extruded bar 220 is formed, and the billet falls on the required position by using the principle of free fall after forming, and is transported to the next station through the conveyor 11 . The conveyor is prior art and can be a conveyor belt.

[0036] The transmission mechanism and the movable mold mechanism are connected by a crank slider mechanism, and the transmission mechanism includes a main motor 1, a flywheel 20, a clutch 21, a main shaft assembly 3, a brake 4, a pinion 5, a large gear 6, and the main motor It is connected with a first transmission shaft, one end of the first transmission shaft is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com