A blocking removal device for preventing and controlling the blockage of an inclined chute and a method of using the same

A technology of inclined chute and check valve, which is applied in the field of equipment to prevent and remove material blockage, can solve the problems of large safety hazards and low labor efficiency, and achieve the effects of good life, reliable performance and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better describe the present invention, a blockage-clearing device for preventing oblique chute blockage and its usage method according to the present invention will be further described in detail in conjunction with the accompanying drawings.

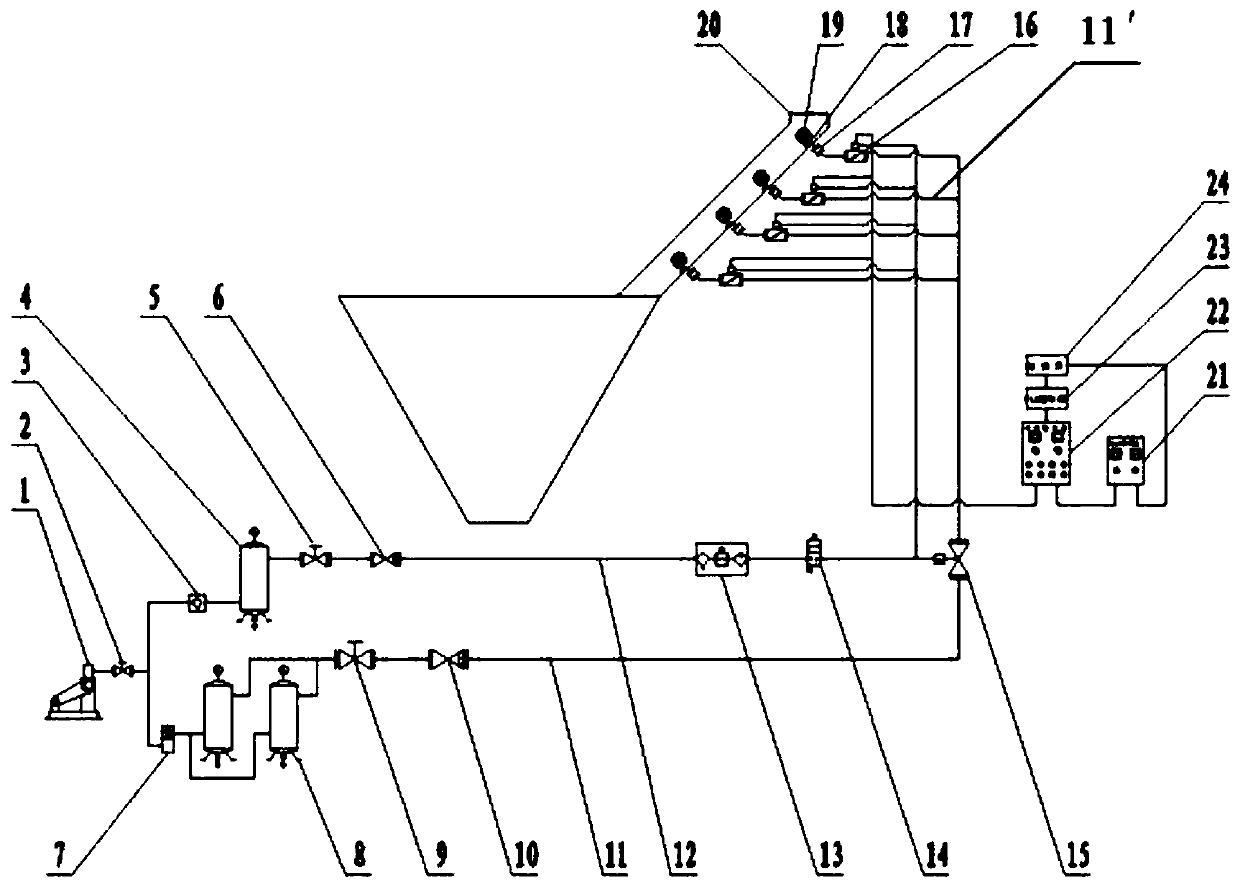

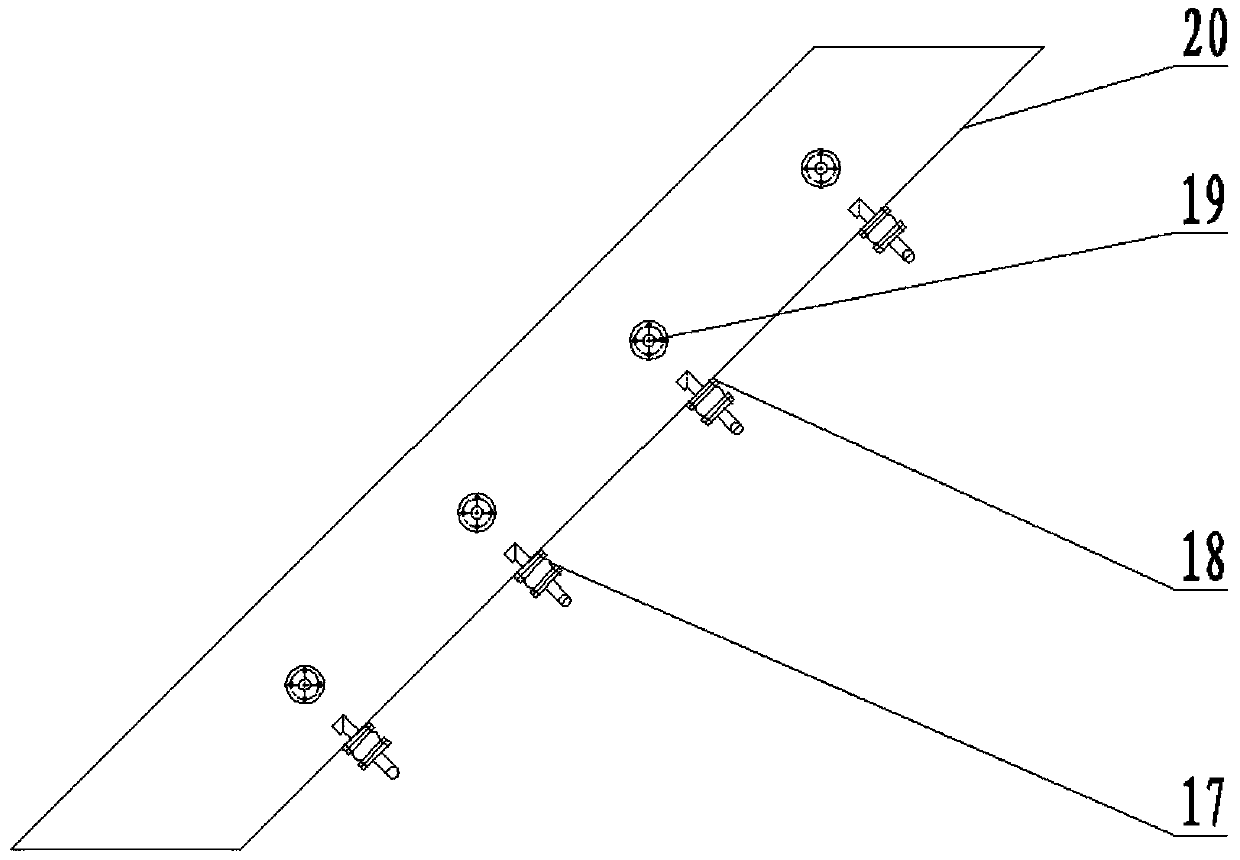

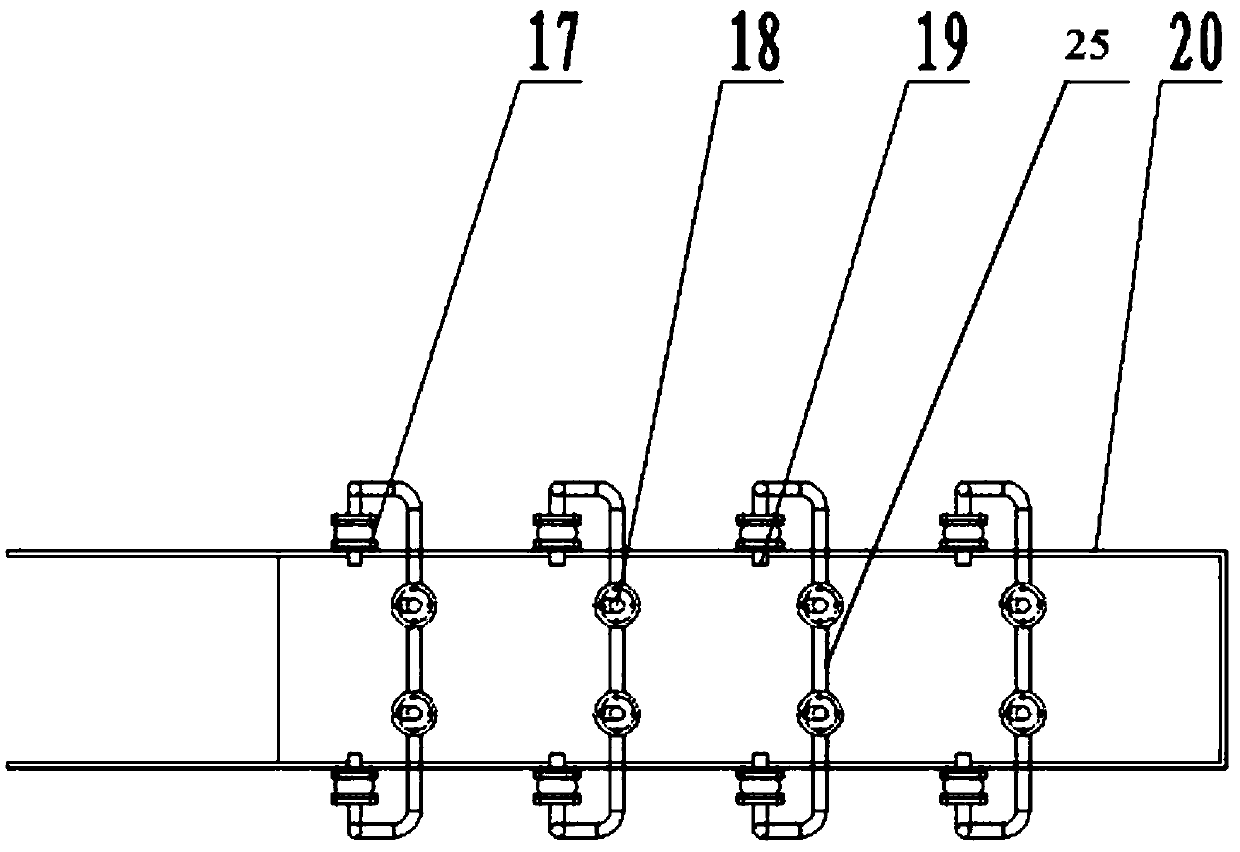

[0034] Depend on figure 1 Shown is a front view structural diagram of a blockage clearing device for preventing and controlling inclined chute blockage of the present invention and combined with figure 2 , image 3 It can be seen that a blockage-clearing device for preventing and preventing inclined chute blockage of the present invention is composed of an air source system, a control airflow pipeline system, a working airflow pipeline system, an electric control system and an injection system. The inclined chute 20 is a rectangular cross-section, and the injection system includes an air injection pipe 25, a bottom plate nozzle 18, and a side plate nozzle 19 arranged in parallel from bottom to top outside the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com