H-ZBaF type optical glass and preparation method thereof

An optical glass and optical-like technology, which is applied in the field of H-ZBaF optical glass and its preparation, can solve the problems of high glass price, easy crystallization of glass, increased glass cost, etc., and achieves good melting performance, good consistency, easy to use molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to specific embodiments. The description in this section is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

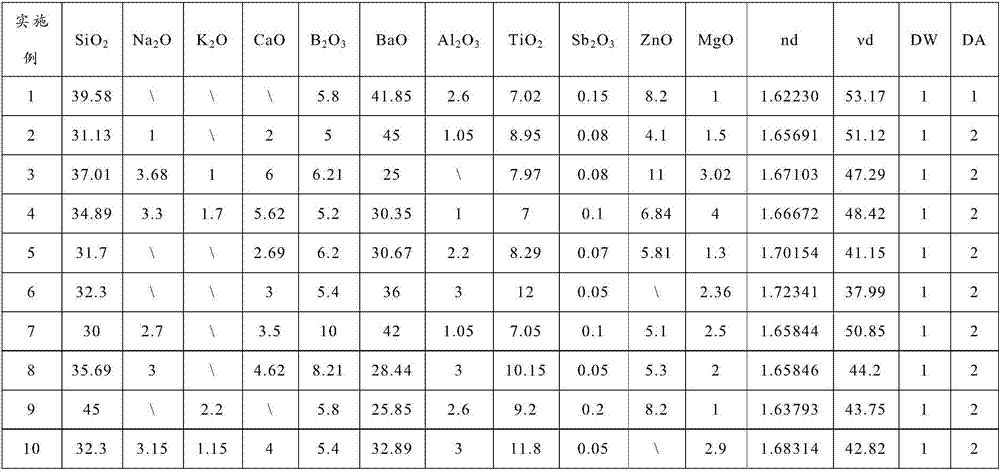

[0013] This embodiment provides an H-ZBaF-based optical glass, and the weight fraction of its chemical composition is: SiO 2 : 30 to 45 parts, CaO: 0 to 6 parts, B 2 O 3 : 5 to 10 parts, BaO: 25 to 45 parts, Al 2 O 3 : 0 to 3 parts, TiO 2 : 7 to 12 parts, Sb 2 O 3 : 0 to 0.2 parts, ZnO: 0 to 11 parts, MgO: 1 to 4 parts, R 2 O: 0 to 5 parts, wherein the R 2 O includes K 2 O, Na 2 One or both of O.

[0014] As a preferred solution, the weight fraction of the chemical composition of the H-ZBaF optical glass is: SiO 2 : 30 to 40 parts, CaO: 2.0 to 4.6 parts, B 2 O 3 : 5.2 to 8.2 parts, BaO: 28.4 to 41.9 parts, Al 2 O 3 : 1 to 3 parts, TiO 2 : 7 to 10.2 parts, Sb 2 O 3 : 0.05 to 0.15 parts, ZnO: 5.1 to 8.2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com