a mn 2+ Doped yellow long-lasting luminescent material and preparation method thereof

A technology for long afterglow luminescence and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of short afterglow time, complex preparation process, low luminous intensity, etc., and achieve long afterglow duration, simple preparation method, and luminescence. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A kind of Mn 2+ Doped yellow long-lasting luminescent material, the chemical expression of which is Ca 1.998 sn 1.974 Al 2 o 9 : 0.002Mn 2+ , 0.026Gd 3+ .

[0027] The Mn 2+ A method for preparing a doped yellow long-lasting luminescent material, comprising the following steps:

[0028] (1) Ca 1.998 sn 1.974 Al 2 o 9 : 0.002Mn 2+ , 0.026Gd 3+ Stoichiometric ratio shown in molecular formula, weigh 0.38712g CaCO 3 , 0.57592g SnO 2 , 0.30201g Al(OH) 3 , 0.00034g MnO 2 and 0.00912g Gd 2 o 3 as a raw material;

[0029] (2) Grinding each raw material component to micron level to obtain raw material powder;

[0030] (3) Calcining the raw material powder at 1500°C under an air atmosphere, and cooling to room temperature with the furnace after 10 hours to obtain a calcined product;

[0031] ⑷ After the calcined product is ground, the yellow long-lasting luminescent material can be obtained.

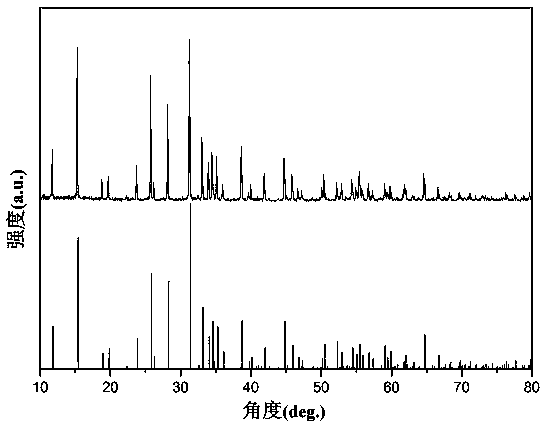

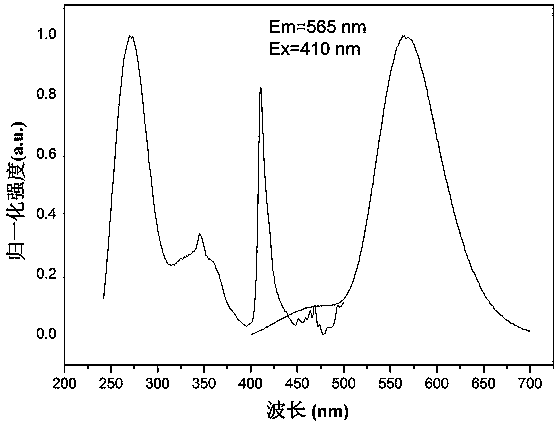

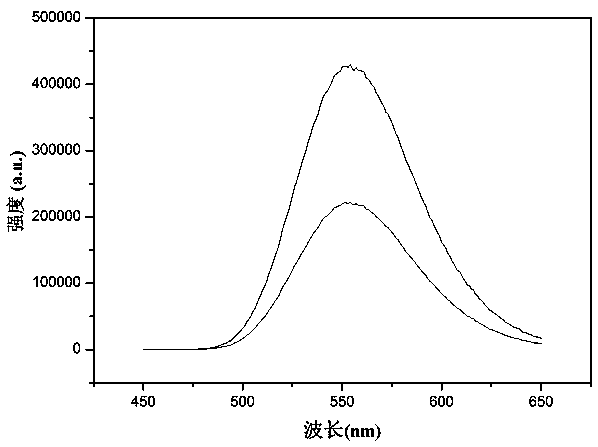

[0032] figure 1 Shown is the XRD spectrum of the yellow ...

Embodiment 2

[0039] Example 2 A kind of Mn 2+ Doped yellow long-lasting luminescent material, the chemical expression of which is Ca 1.998 sn 1.974 Al 2 o 9 : 0.002Mn 2+ , 0.026Ho 3+ .

[0040] The Mn 2+ A method for preparing a doped yellow long-lasting luminescent material, comprising the following steps:

[0041] ⑴ Press Ca 1.998 sn 1.974 Al 2 o 9 : 0.002Mn 2+ , 0.026Ho 3+ For the stoichiometric ratio shown in the molecular formula, weigh 0.38697g CaCO 3 , 0.57569g SnO 2 , 0.30189g Al(OH) 3 , 0.00034g MnO 2 and 0.00951g Ho 2 o 3 as a raw material;

[0042] (2) Grinding each raw material component to micron level to obtain raw material powder;

[0043] (3) Calcining the raw material powder at 1500°C under an air atmosphere, and cooling to room temperature with the furnace after 10 hours to obtain a calcined product;

[0044] ⑷ After the calcined product is ground, the yellow long-lasting luminescent material can be obtained.

Embodiment 3

[0045] Example 3 A kind of Mn 2+ Doped yellow long-lasting luminescent material, the chemical expression of which is Ca 1.998 sn 1.980 Al 2 o 9 : 0.002Mn 2+ , 0.020 Ce 3+ .

[0046] The Mn 2+ A method for preparing a doped yellow long-lasting luminescent material, comprising the following steps:

[0047] ⑴ Press Ca 1.998 sn 1.980 Al 2 o 9 : 0.002Mn 2+ , 0.020 Ce 3+ Stoichiometric ratio shown in molecular formula, weigh 0.38731g CaCO 3 , 0.57799g SnO 2 , 0.30224g Al(OH) 3 , 0.00034g MnO 2 and 0.00703 g CeO 2 as a raw material;

[0048] (2) Grinding each raw material component to micron level to obtain raw material powder;

[0049] (3) Calcining the raw material powder at 1500°C under an air atmosphere, and cooling to room temperature with the furnace after 10 hours to obtain a calcined product;

[0050] ⑷ After the calcined product is ground, the yellow long-lasting luminescent material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com