Preparation method of blue long-afterglow luminescent powder

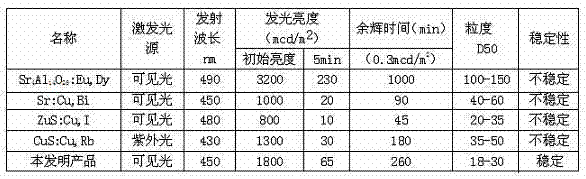

A long afterglow luminescent powder, blue technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of not being widely used, blackening failure light absorption time, poor chemical stability, etc., to achieve long afterglow time and fast light absorption , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1, A preparation method of blue long afterglow luminescent powder, comprising the following steps:

[0028] 1. Add 100 kg of zinc sulfide powder, 5 kg of germanium chloride powder, 1000 ml of silver nitrate aqueous solution with a concentration of 20 g / L, 100 g of bismuth oxide, and 1000 g of samarium nitrate aqueous solution with a concentration of 20 g / L in the ball mill mixer. Milliliters, concentration is 600 milliliters of potassium iodide aqueous solution of 200g / L, the magnesium chloride of 3000g, the sublimation sulfur of 2000g, and mix 18 hours;

[0029] 2. After mixing the raw materials, put them into a quartz crucible and seal it with a cover, put it into a high-temperature furnace, cover it and seal it, keep it at 1130°C for 4 hours, cool it down to 600°C, take it out of the furnace to get the block, and cool it down;

[0030] 3. Check the blocks cooled to room temperature under the purple light to detect non-luminous substances, add 2000 ml of chlo...

Embodiment 2

[0031] Example 2, A preparation method of blue long afterglow luminescent powder, comprising the following steps:

[0032] 1. Add 130 kg of zinc sulfide powder, 8 kg of germanium chloride powder, 1,000 ml of silver nitrate aqueous solution with a concentration of 30 g / L, 50 g of bismuth oxide, and 1,000 g of samarium nitrate aqueous solution with a concentration of 30 g / L in the ball mill mixer. Milliliters, concentration is 800 milliliters of potassium iodide aqueous solution of 180g / L, the magnesium chloride of 4000g, the sublimation sulfur of 3000g, and mix 12 hours;

[0033] 2. After mixing the raw materials, put them into a quartz crucible, cover and seal them, put them into a high-temperature furnace, cover them and seal them, keep them warm at 1150°C for 4 hours, cool them down to 600°C, take them out of the furnace to get blocks, and cool them down;

[0034] 3. Check the blocks cooled to room temperature under the purple light to detect non-luminous substances, add 1...

Embodiment 3

[0035] Example 3, A preparation method of blue long afterglow luminescent powder, comprising the following steps:

[0036] 1. Add 150 kg of zinc sulfide powder, 15 kg of germanium chloride powder, 2000 ml of silver nitrate aqueous solution with a concentration of 50 g / L, 80 g of bismuth oxide, and 1500 ml of samarium nitrate aqueous solution with a concentration of 50 g / L in the ball mill mixer. Milliliters, concentration is 800 milliliters of potassium iodide aqueous solution of 30g / L, the magnesium chloride of 3000g, the sublimation sulfur of 2000g, and mix 15 hours;

[0037] 2. After mixing the raw materials, put them into a quartz crucible, cover and seal them, put them into a high-temperature furnace, cover them and seal them, keep them warm at 1140°C for 5 hours, cool them down to 600°C, take them out of the furnace to get blocks, and cool them down;

[0038] 3. Check out the non-luminous substances in the material block cooled to room temperature under the purple ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com