Construction technology of tourism ecological road and rural highway through soil body solidification

A construction technology and soil technology, applied in the direction of roads, applications, roads, etc., can solve the problems of high cost, high maintenance cost, high energy consumption, etc., and achieve the effect of short construction period, high solution cost, and ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

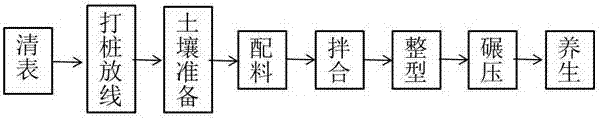

[0038] Such as figure 1 Shown, the present invention provides and utilizes solidification of soil body as the construction technology of tourism ecological road, rural road, and road base construction technology comprises the following steps:

[0039] (1) Surface cleaning: pre-treat the base of the pre-filled roadbed to drain the water on the roadbed.

[0040] (2) Pile driving and setting out: release the middle pile of the subgrade on the base of the subgrade, and release the side piles according to the middle pile, and determine the toe line of the embankment located on both sides of the embankment according to the wide fill size of the toe of the embankment. The area between the two toe lines shall be cleared; side piles shall be nailed outside the edges of both sides of the layer to be paved for hanging lines to control the paving boundaries, marking thickness and elevation. Restoring the center line on the road bed, set up one pile for the straight section 15m-20m, and ...

Embodiment 2

[0054] The difference with embodiment 1 is:

[0055] The soil curing agent for the subgrade and pavement layers consists of 20 parts of ionic surfactant, 10 parts of stabilizer, 5 parts of dispersant, 5 parts of water reducer, 5 parts of reinforcing agent, 5 parts of water repellent and 50 parts of water.

[0056] The mix ratio of road base and pavement layer: 94 parts of soil, 6 parts of cement, and 0.01 part of soil curing agent is added by external mixing.

[0057] The unconfined compressive strength of the obtained road is 5.0Mpa, the bearing ratio is 45%, the water stability strength coefficient is 1.10, and the freeze-thaw strength coefficient is 0.96.

Embodiment 3

[0059] The difference with embodiment 1 is:

[0060] The soil curing agent for the subgrade and pavement layers consists of 30 parts of ionic surfactant, 10 parts of stabilizer, 10 parts of dispersant, 8 parts of water reducer, 8 parts of reinforcing agent, 14 parts of water repellent and 20 parts of water.

[0061] The mix ratio of road base and pavement layer: 90 parts of soil, 10 parts of cement, and 0.015 parts of soil curing agent are added by external mixing.

[0062] The unconfined compressive strength of the obtained road is 6.0Mpa, the bearing ratio is 55%, the water stability strength coefficient is 1.12, and the freeze-thaw strength coefficient is 0.97.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com