Intelligently-controlled flue-cured tobacco biomass burning machine

An intelligent control and burner technology, which is applied in the combustion of solid fuel, combustion equipment, and tobacco preparation, can solve the problems of randomness of the quantity and frequency error of feeding, and achieve a high degree of automation, good safety performance and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

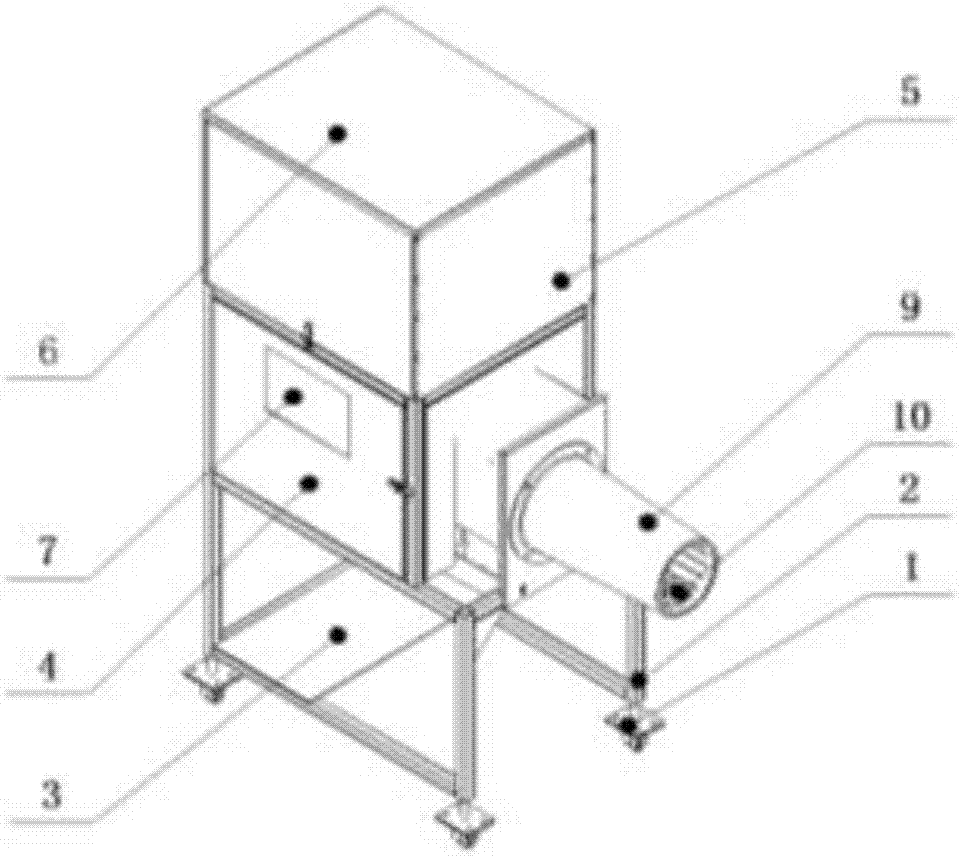

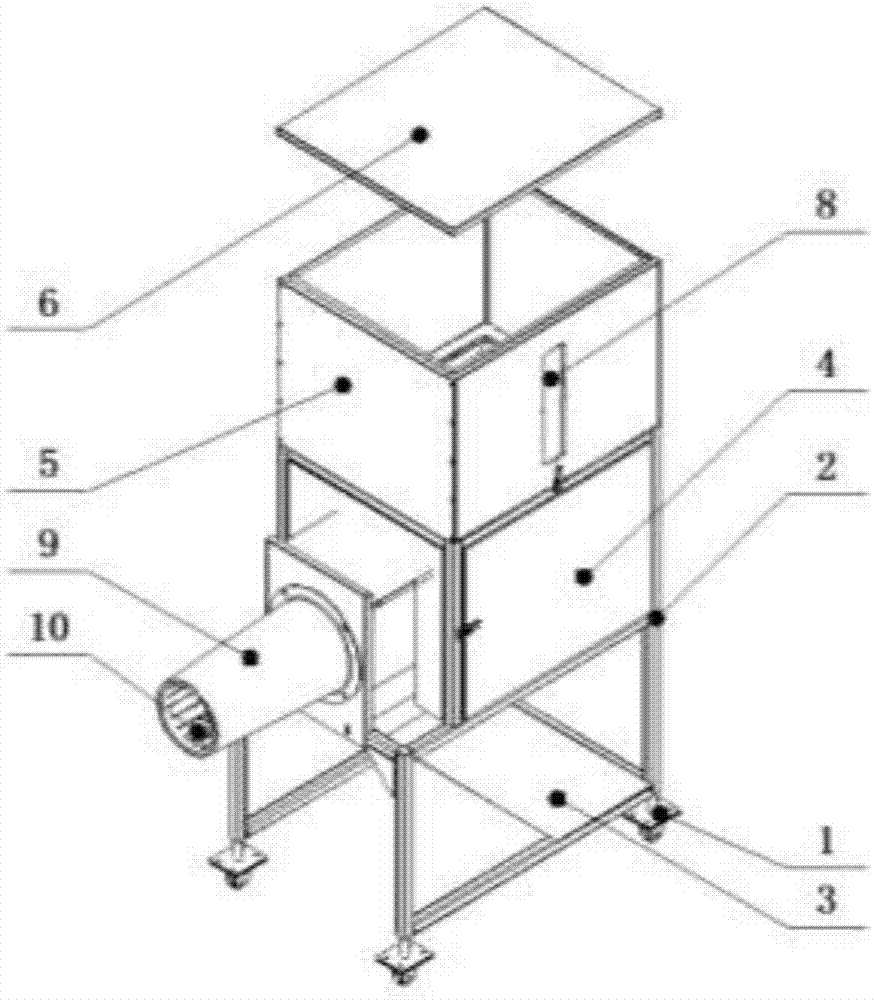

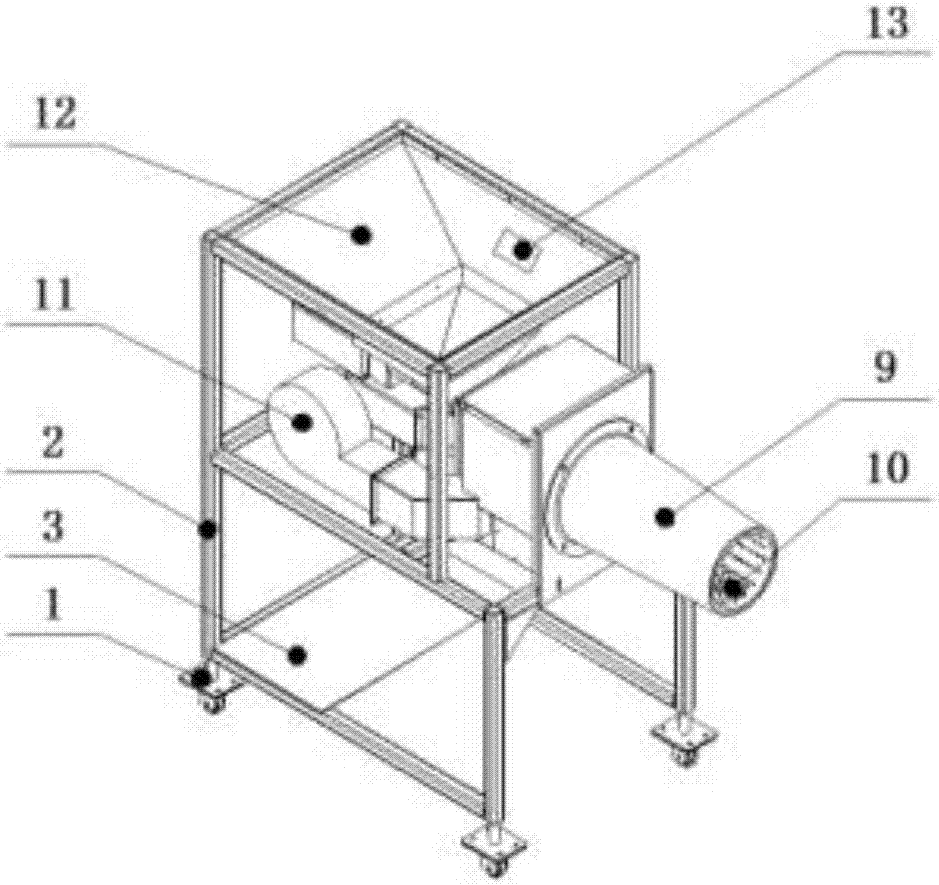

[0021] See Figure 1-Figure 9 , an intelligently controlled flue-cured tobacco biomass burner, comprising: a frame 2, casters 1 installed on the lower end surface of the bottom of the frame 2, a counterweight plate 3 fixed on the bottom of the lower layer of the frame 2, a lower protective cover 4 and an upper protective cover The cover 5 is respectively fixed on the outer periphery of the lower layer of the frame 2 and the outer periphery of the upper layer of the frame 2, the upper end surface of the lower protective cover 4 is aligned with the lower end surface of the upper protective cover 5, and the top cover 6 is embedded in the top of the upper protective cover 5. Take it off when loading, and a control panel 7 is installed on the side of the lower protective cover 4 close to the centrifugal fan 11, and a material observation port 8 is provided on one side of the upper protective cover 5, and the height of the material observation port 8 is adapted to the height of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com