Efficient drying device for food materials

A drying device and high-efficiency technology, applied in the direction of drying gas arrangement, drying solid materials, drying chamber/container, etc., can solve the problems of unsatisfactory effect and incomplete drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

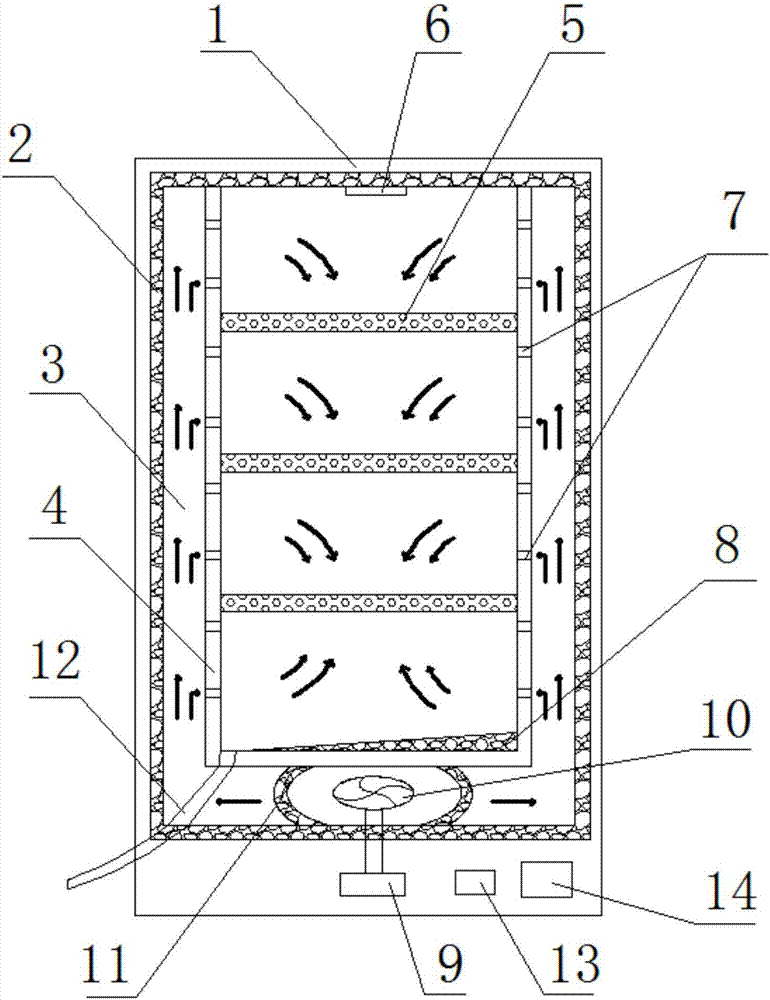

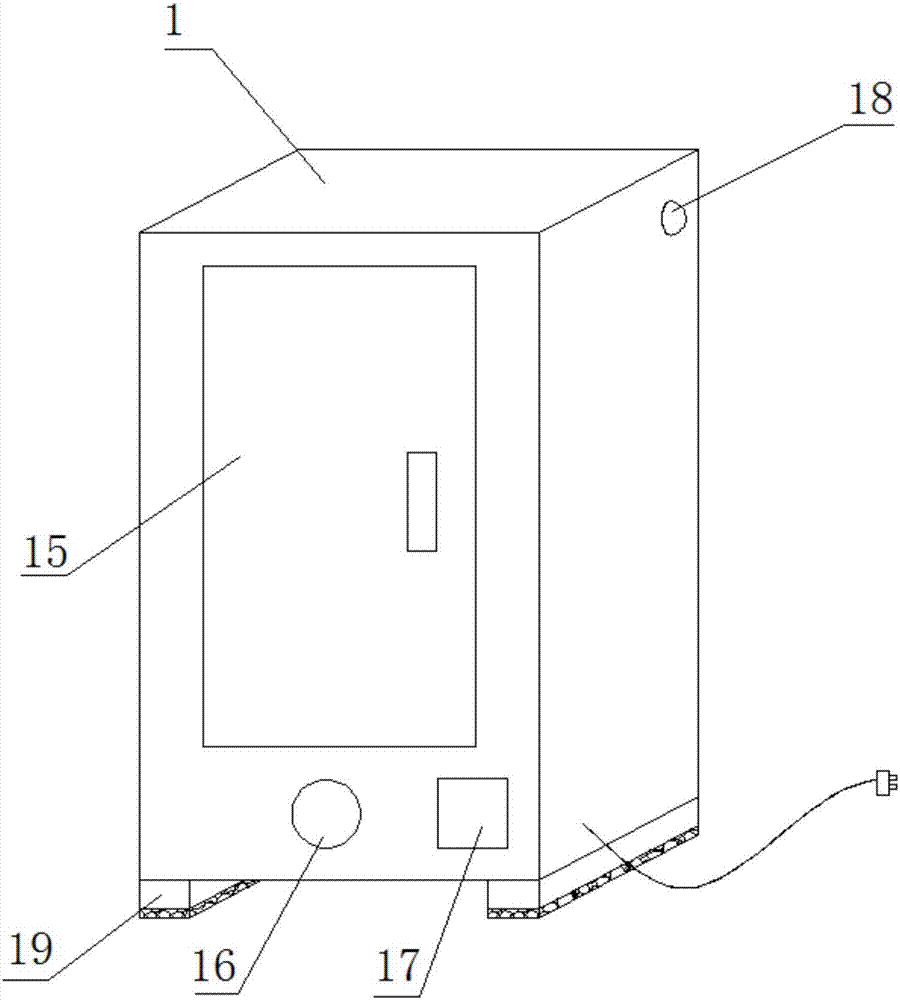

[0022] Example: see Figure 1-2 , a high-efficiency drying device for food materials according to the present invention, comprising a cabinet body 1, an inner container 4, a shelf 5, and a base 19, one side of the cabinet body 1 is hinged to a sealed door 15 through a hinge, and the sealed door 15 The lower end is provided with a control switch 16, the right side of the control switch 16 is provided with a display screen 17, and the upper end of the right side of the cabinet 1 is provided with an alarm 18, the alarm model: YDLB-MK-10A, the inside of the cabinet 1 An inner container 4 is provided, and an insulating layer 2 is arranged between the inner container 4 and the cabinet body 1. The insulating layer 2 is made of foam to enhance the thermal insulation effect. Between the insulating layer 2 and the inner container 4, there is Air duct 3, a temperature sensor 6 is fixed on the inner top of the liner 4, the temperature sensor model: pt100, three placement racks 5 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com