Simulation testing device for electrical conductivity of powdery electrode material

An electrode material and simulation test technology, applied in the direction of material impedance, etc., can solve the problems that are not suitable for accurate measurement of powder electrode testing, and achieve the effect of speeding up the research and development progress, low test condition requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

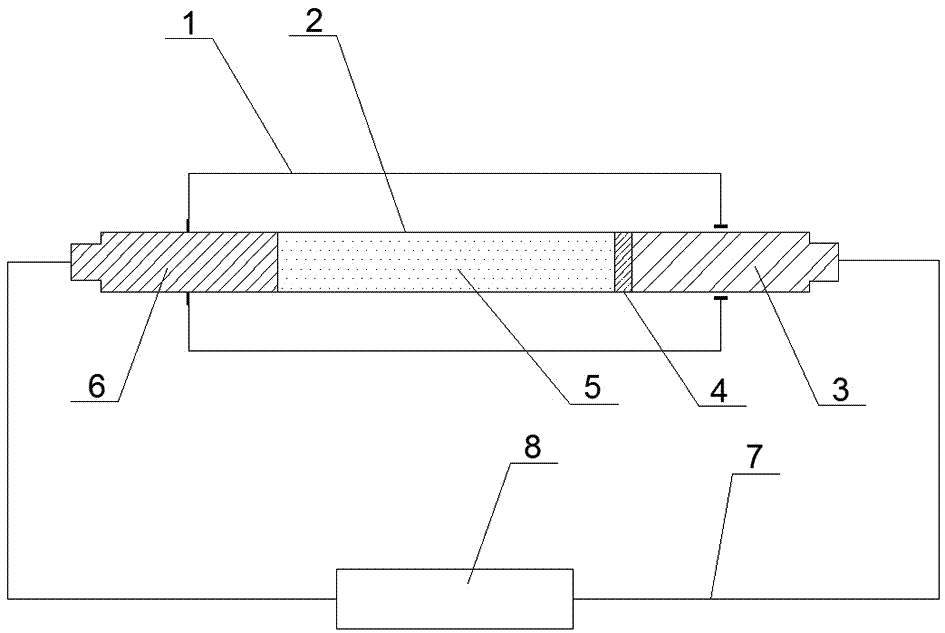

[0014] figure 1 The shown powdered electrode material conductivity simulation test device includes an outer cylinder 1, an inner cylinder 2, a movable terminal 3, a spacer 4, a powdered electrode material 5, a fixed terminal 6, a wire 7 and a tester 8. The inner cylinder 2 is the main component of the testing device, and the thin-walled inner cylinder 2 is made of insulating material, and in this embodiment, it is made of plastic. The inner cylinder body 2 is placed in the outer cylinder body 1, the inner cylinder body 2 coaxial with the outer cylinder body 1 runs through the outer cylinder body 1 in the center and exposes both ends, and the inner body 2 and the outer cylinder body 1 of the fixed terminal 6 are plugged into the left end It is fixedly connected, and the inner cylinder body 2 with the movable terminal 3 placed on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com