Projection augmented reality assembly inducing and monitoring system and implementation method thereof

An augmented reality and monitoring system technology, applied in the direction of measuring force, measuring device, force/torque/work measuring instrument, etc., can solve the problems of unqualified assembly process, difficult operation, increase cost, etc., to improve assembly accuracy, The effect of reducing training time and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

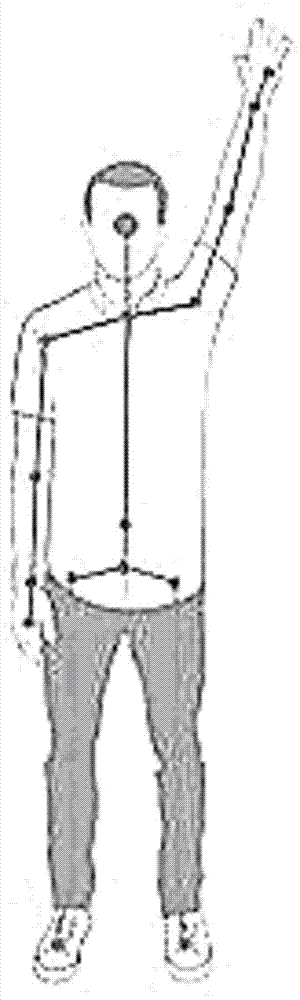

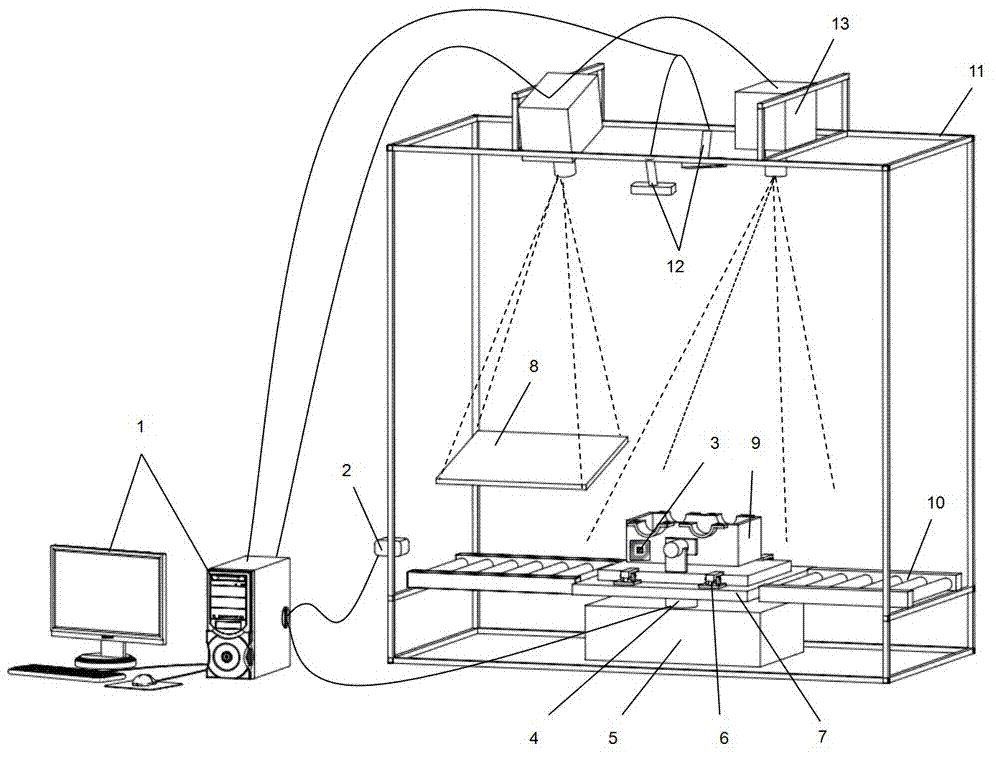

[0039] A projected augmented reality assembly induction and monitoring system, comprising a computer 1 loaded with assembly induction information, an electronic label scanner 2, an electronic label 3, a workbench 7, and a projector group 13, the projector group 13 and the electronic label The scanner 2 is connected to the computer 1 , the projector group 13 is fixed above the workbench 7 through a mounting bracket 11 , and the electronic label 3 is arranged on the operated component 9 .

[0040] The projector group 13 includes at least one projector, figure 1 Two projectors are shown in . When two projectors are used, each projector can project different induction information, so that more assembly induction information can be displayed simultaneously in the assembly space. The projector group 13 can not only project pictures and texts containing inductive information, but also directly project information such as assembly position, tightening direction, and tightening torque ...

Embodiment 2

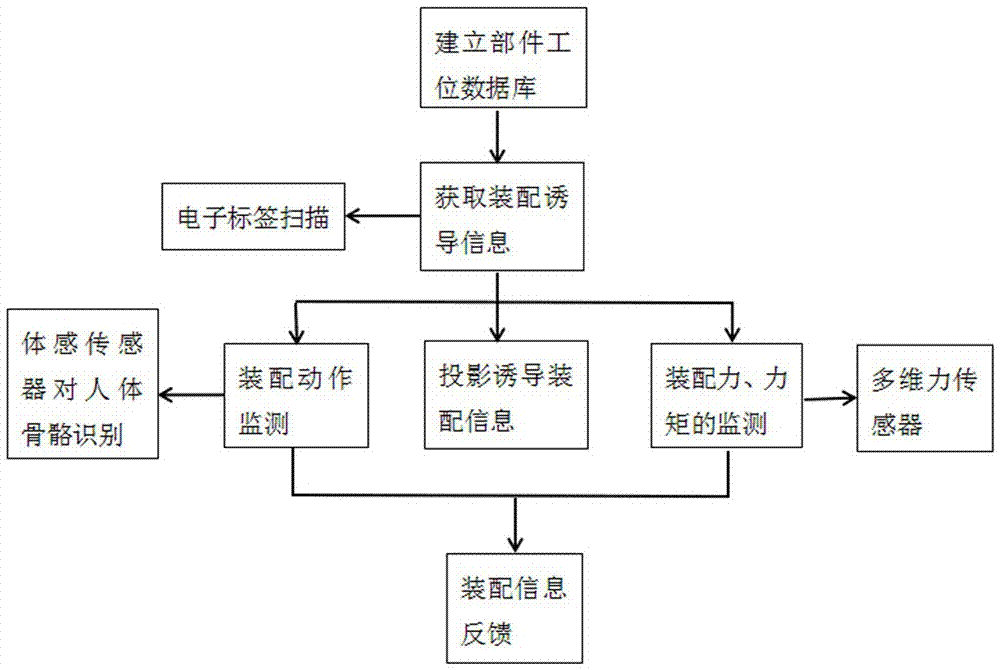

[0049] see Figure 1 to Figure 3 , a projection-type augmented reality assembly induction and monitoring method, comprising the following steps:

[0050] A method for realizing assembly guidance and monitoring of projected augmented reality, comprising the following steps:

[0051] Step 1. Establishing a component station database: the component station database stores assembly induction information, and the assembly induction information is standard data for assembly;

[0052] The component station database can use the component name as the data index to establish assembly induction information when the station assembles various components, including component shape, assembly position, assembly sequence, assembly action animation, tools used, bolt tightening torque and text picture;

[0053] Step 2, component information collection and induction: read the electronic label 3 on the operated component 9 through the electronic label scanner 2, and transmit the read information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com