Explosionproof and flame-retardant structure of lithium battery

A lithium battery and flame retardant technology, applied in secondary batteries, structural parts, battery pack parts, etc., can solve problems such as unbalanced performance of single cells, high danger of high and low temperature use, and reduced battery performance, so as to prevent fires. The effect of burning or even explosion, improving market competitiveness and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

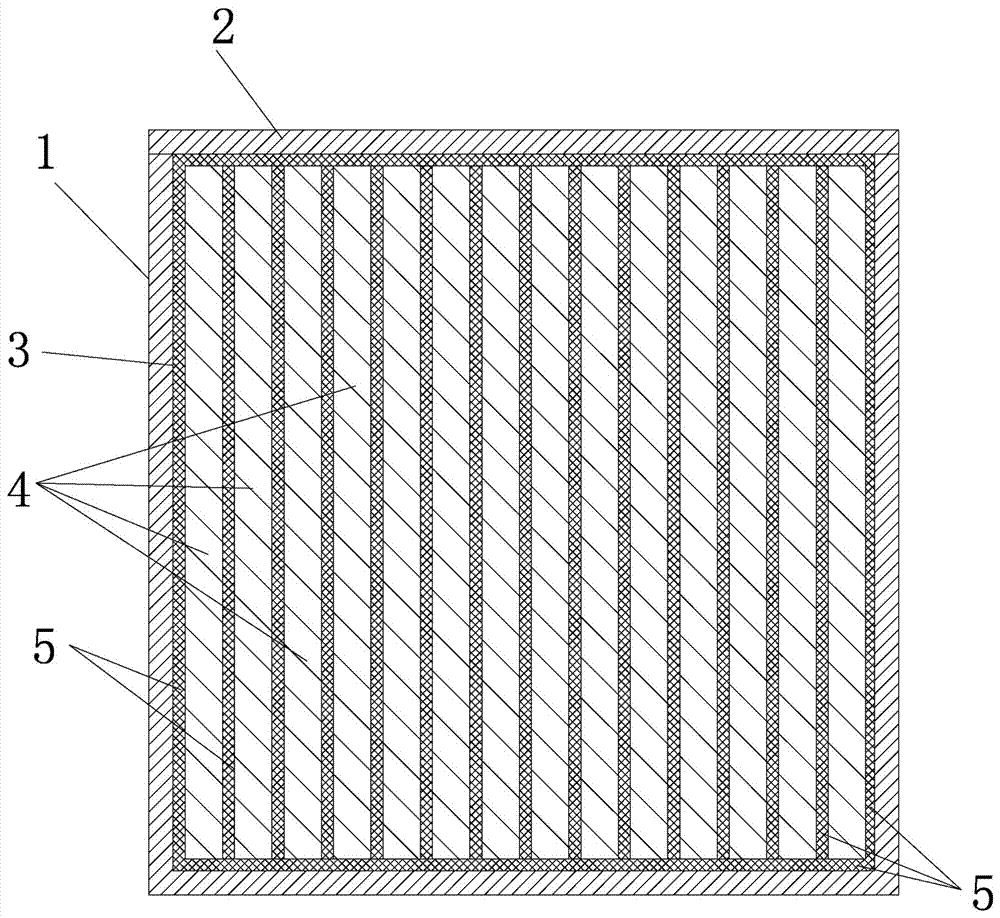

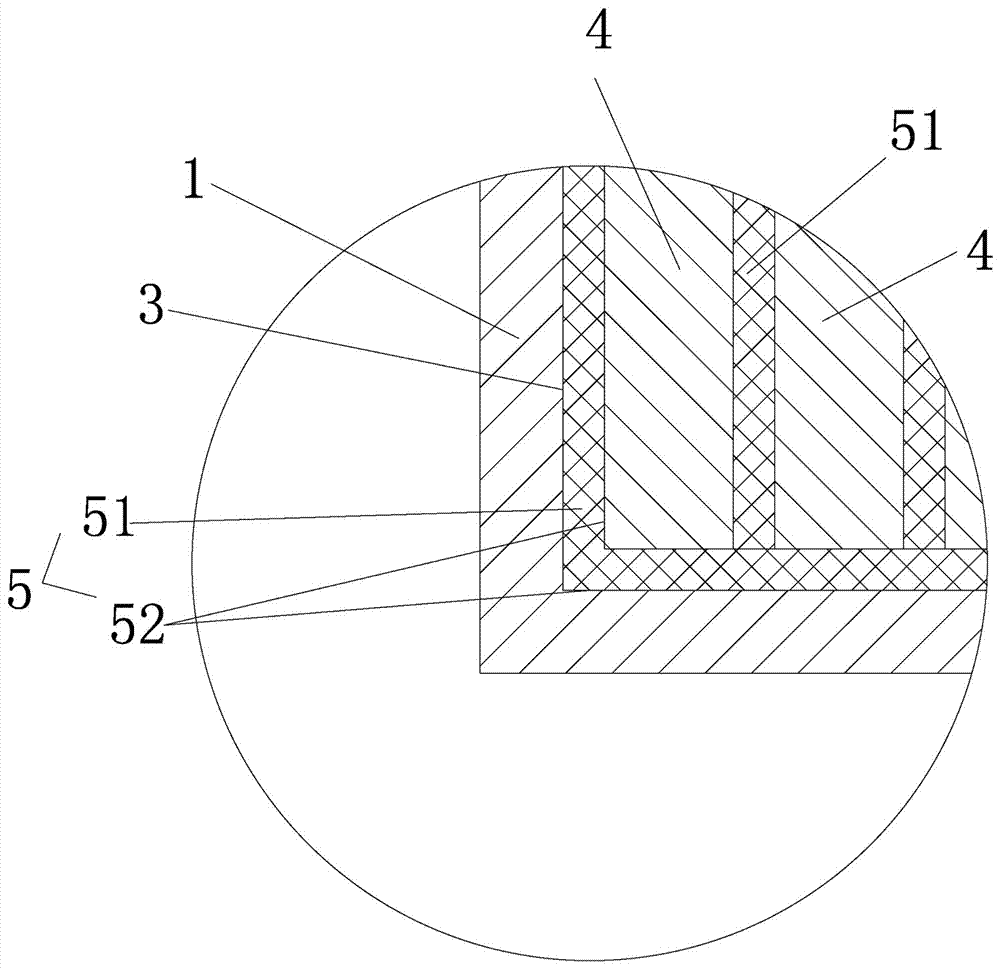

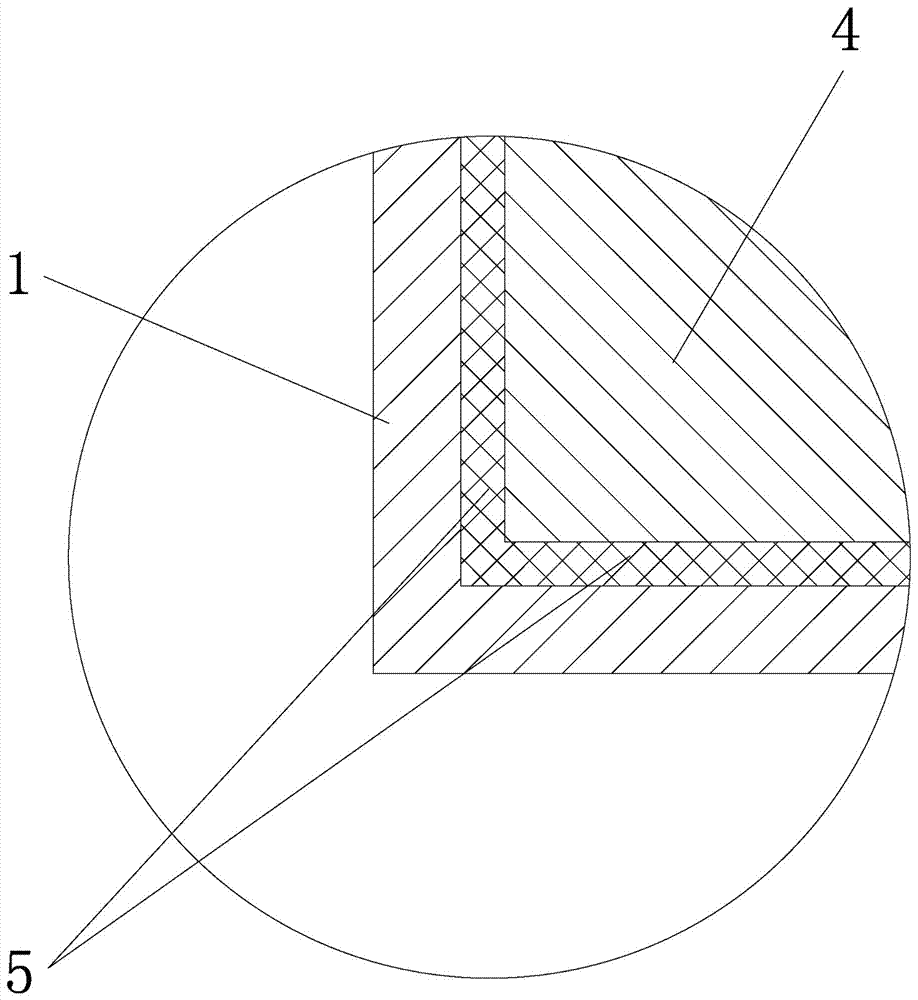

[0016] The present invention will be specifically and further described below in conjunction with the accompanying drawings. An explosion-proof and flame-retardant structure for a lithium battery, which includes a housing 1 and a mask 2. The housing 1 is provided with an accommodation cavity 3 inside, and a plurality of lithium battery packs 4 are installed in the accommodation chamber 3. The lithium battery packs 4 are arranged on the mask 2 The electrode connection is characterized in that: a fire extinguishing layer 5 is provided between the accommodating chamber 3 and the lithium battery pack 4, and the fire extinguishing layer 5 includes a low melting point isolation bag 51 and a fluid flame retardant 52 disposed therein.

[0017] The low-melting point isolation bag 51 is arranged in a hollow rectangular shape, and the lithium battery pack 4 is placed inside the isolation bag.

[0018] The fire extinguishing layer 5 is arranged on the side wall of the accommodating chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com