Chainsaw chain with surface hardness layer defined on cutter links

A technology for cutting parts and chains, which is applied in the direction of saw chains, chain saws, manufacturing tools, etc. It can solve the problems of slow wear process, achieve the effect of improving cutting efficiency, improving operability and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Some example embodiments will now be described more fully hereinafter with reference to the accompanying drawings, in which some but not all example embodiments are shown. Indeed, the examples described and illustrated herein should not be construed as limiting the scope, applicability, or configuration of the disclosure. Rather, these example embodiments are provided so that this disclosure will satisfy applicable legal requirements. Like reference numerals refer to like elements throughout. Furthermore, as used herein, the term "or" shall be construed as a logical operator whose result is true if one or more of its operands is true. As used herein, operable coupling shall be understood to refer to direct or indirect connections which, in either case, enable functional interconnection of components that are operably connected to each other.

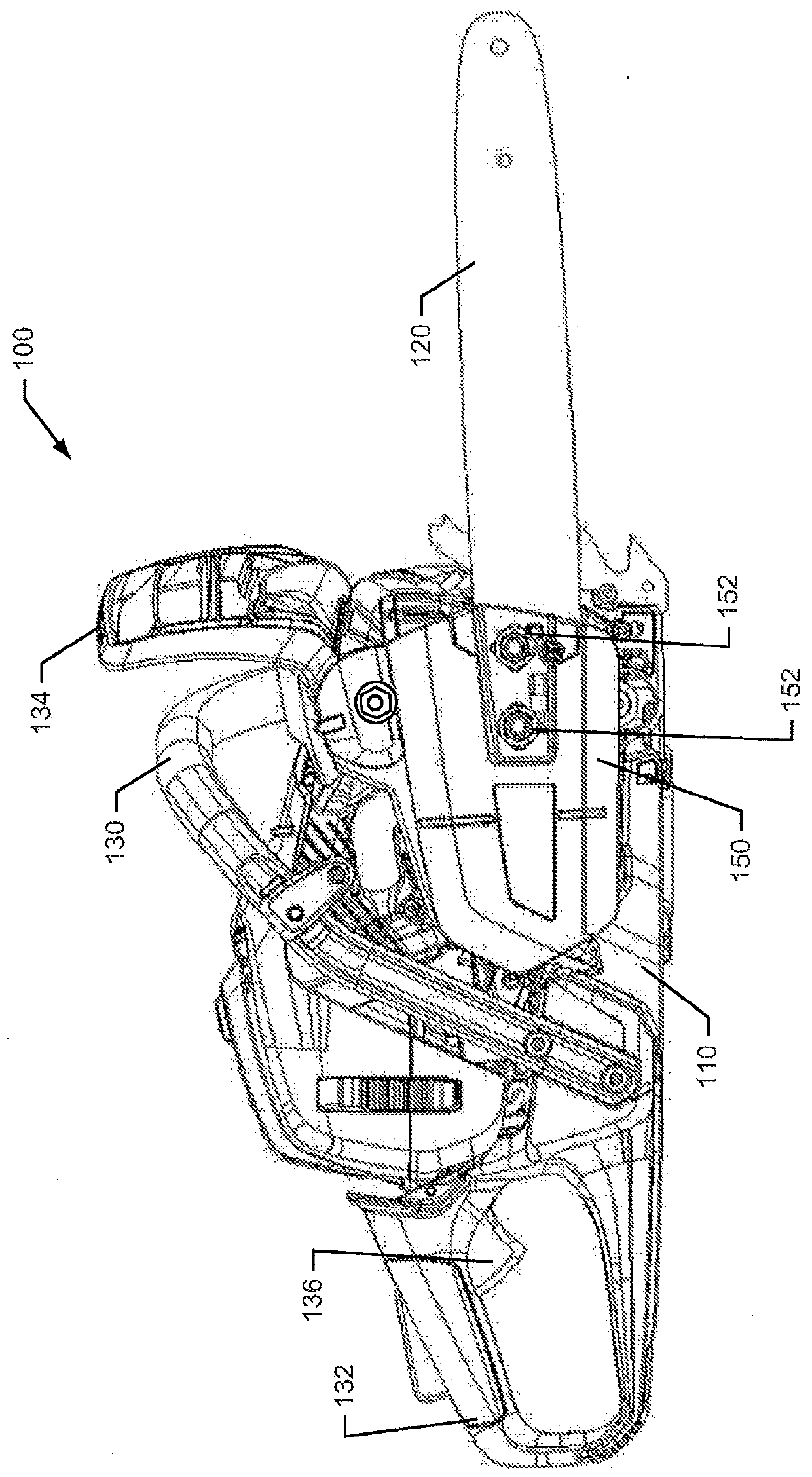

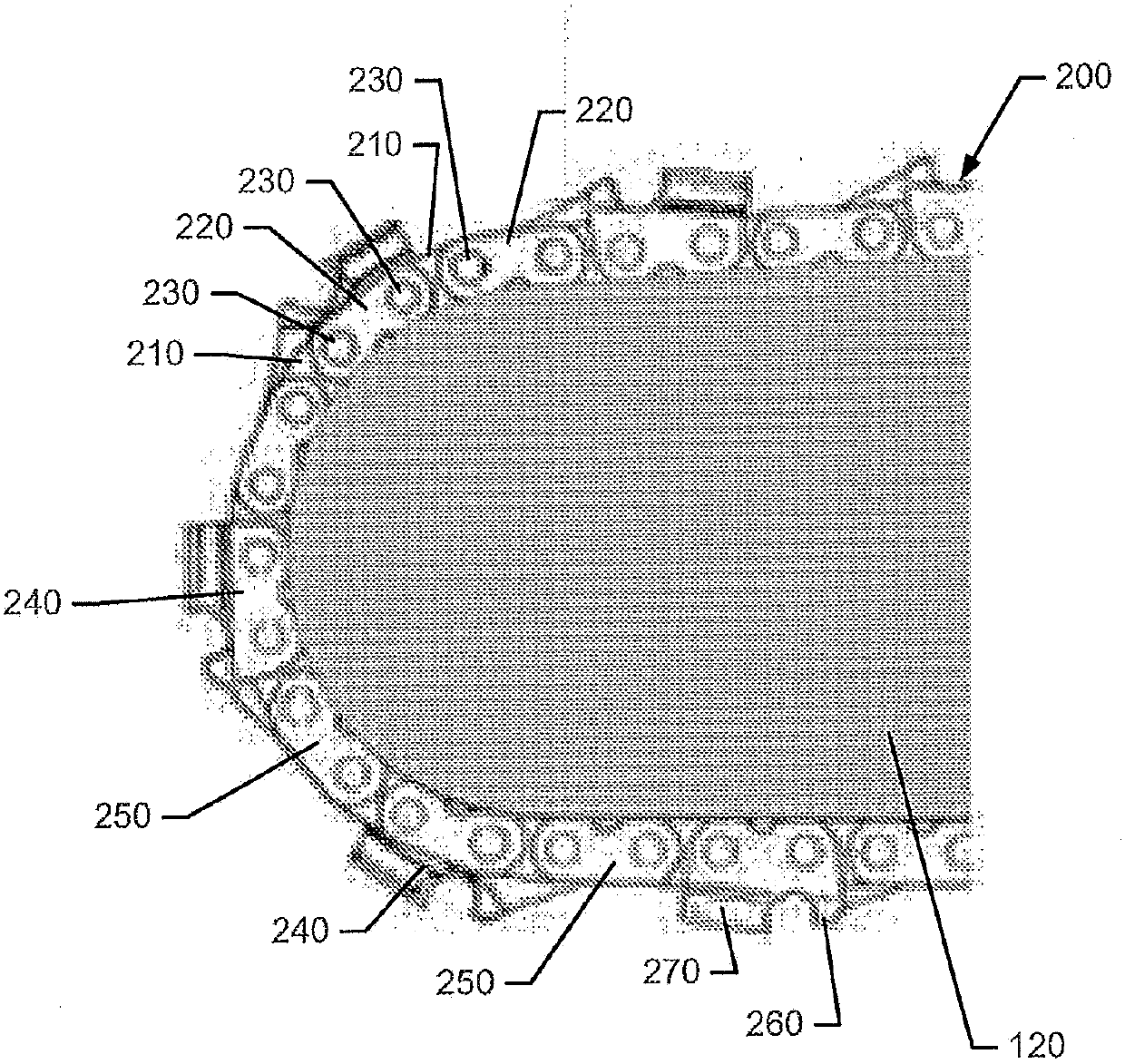

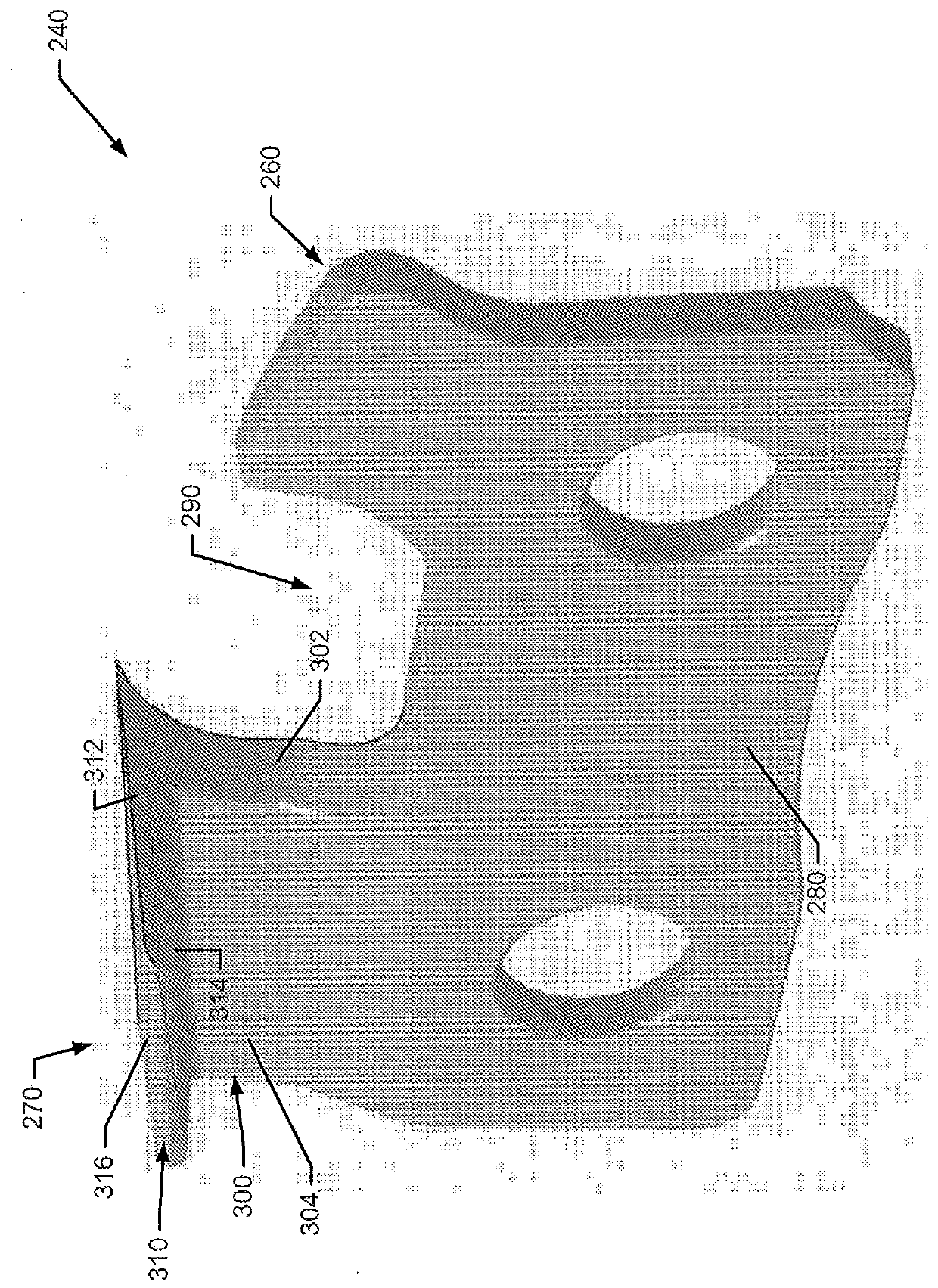

[0014] figure 1 A side view of a chainsaw 100 according to an exemplary embodiment is shown. Such as figure 1 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com