Process for preparing a storage-stable silicone resin

A storage-stable, silicone-based technology, applied in coatings and other directions, which can solve problems such as cost impact, operator health and safety risks, untimely condensation of silicone resin gelation, etc., to achieve a simplified method, no health and safety risks , the effect of no environmental risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0171] A) Raw materials used:

[0172] - Chlorotrimethylsilane from the company Sigma-Aldrich.

[0173] -Dimethyldichlorosilane from the company Sigma-Aldrich.

[0174] -Methyltrichlorosilane from the company Sigma-Aldrich.

[0175] - Soften water.

[0176] - AH: Toluene from the company VWR International: Normapur grade.

[0177] - CA: Aqueous hydrochloric acid (-37 or 33% by weight) from VWR International.

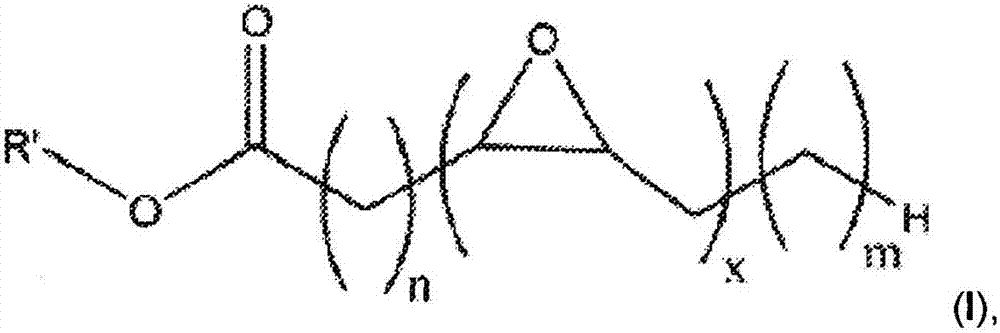

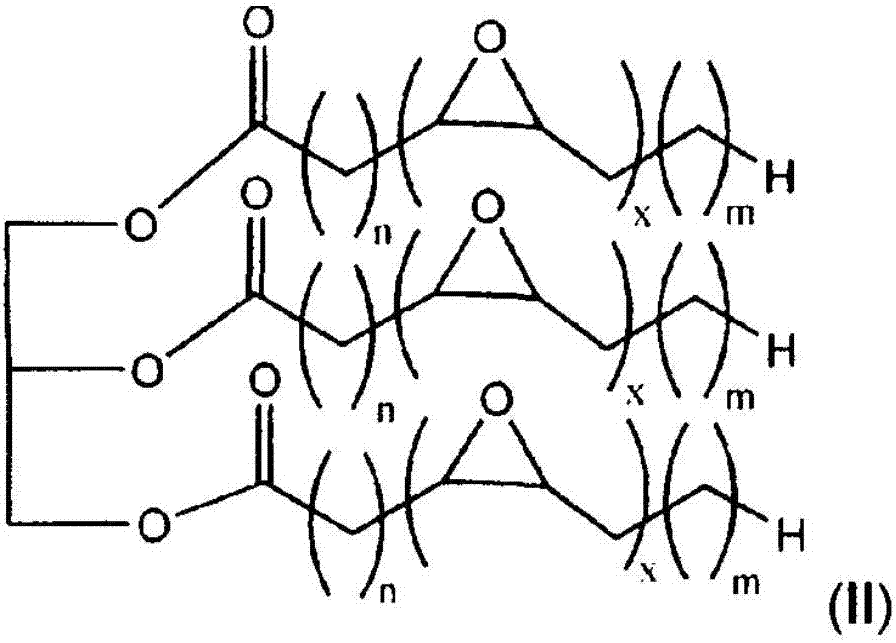

[0178] -Organic compound O: Dehysol R B35 from BTC Corporation: 2-ethylhexyl ester of epoxidized fatty acid (CAS68082-34-8).

[0179] For all examples, the term "neutral pH" means a pH of 7 (pH paper accuracy).

[0180] B) Preparation of mixture X according to the invention

[0181] 1. Mixtures X1 according to the invention

[0182] According to the direct hydrolysis method, a chlorosilane mixture consisting of 4.38 g of chlorotrimethylsilane, 8.55 g of dimethyldichlorosilane, and 26.95 g of methyltrichlorosilane was added dropwise to the stirred reactor under a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com