Electromagnetic diaphragm type on-demand microdroplet preparation apparatus

A preparation device, diaphragm type technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of restricting rapid application and development, low droplet frequency, difficult to realize non-conductive liquid droplet preparation, etc., to improve micro-jet Efficiency, the effect of simplifying the test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

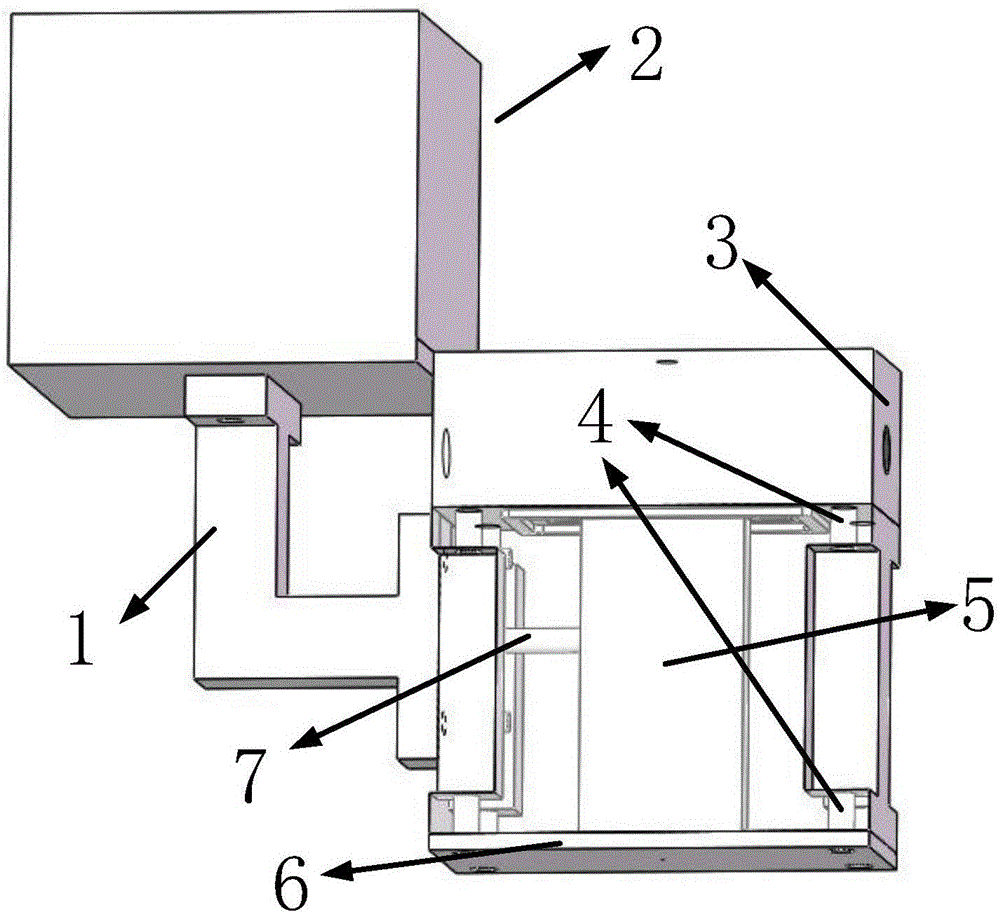

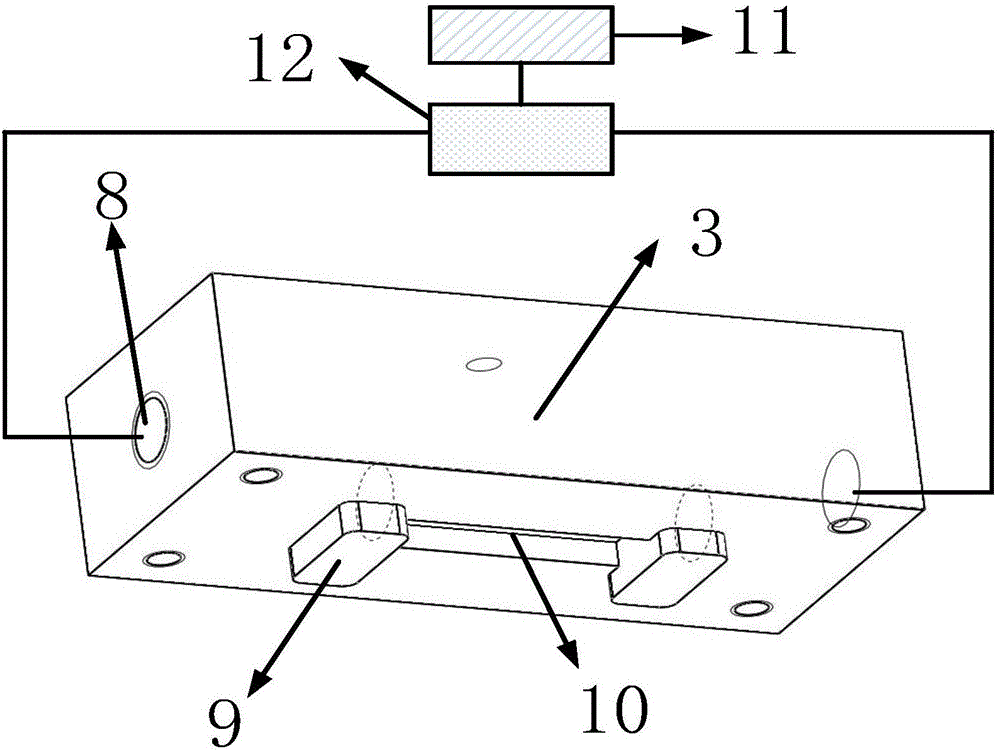

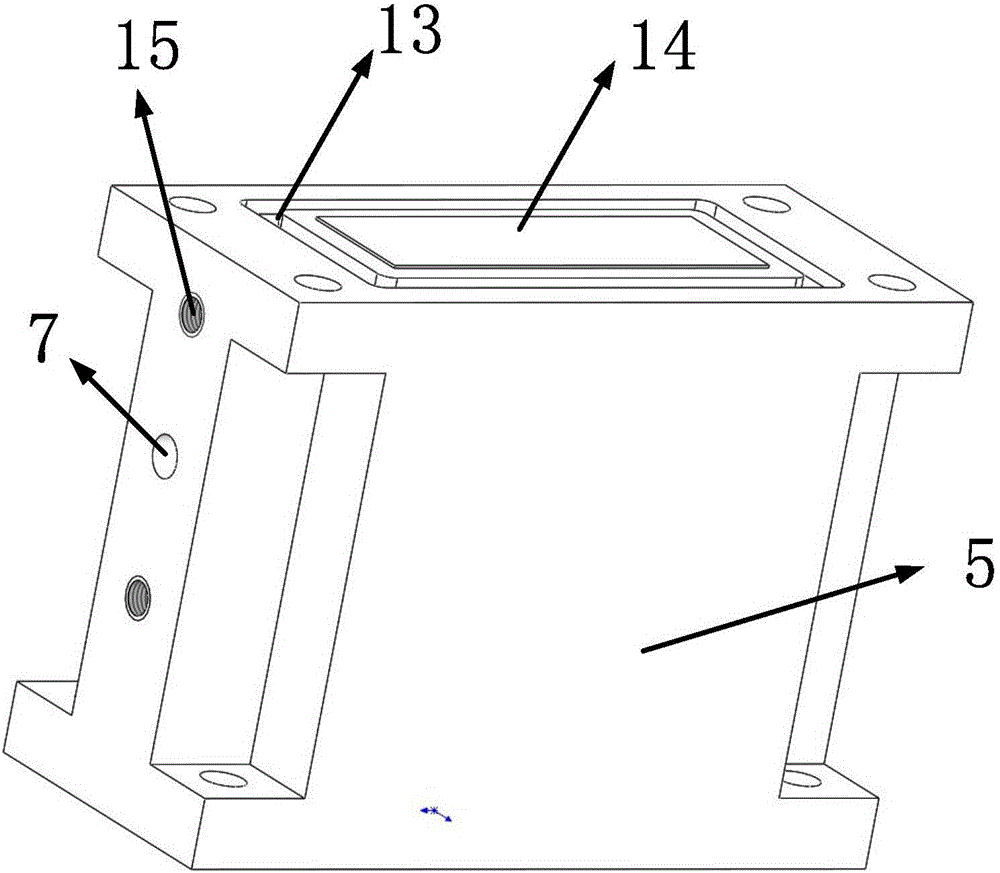

[0021] An electromagnetic diaphragm-type on-demand droplet preparation device. The Ampere force received by the liquid metal above the diaphragm is used as the driving source. When the Ampere force is applied to the diaphragm, the diaphragm is deformed, resulting in an increase in the internal pressure of the liquid injection cavity, forcing the fluid to Periodic droplets are formed through the nozzle.

[0022] see Figure 1-3 , the embodiment of the present invention is provided with a conduit 1, a liquid storage chamber 2, a driving device 3, a bolt fixing hole 4, an injection chamber 5, a lower cover plate 6 with a nozzle, an orifice 7, a wire connection hole 8, and a copper electrode 9 , drive chamber 10, signal source 11, power amplifier 12, injection device sealing groove 13, diaphragm 14, injection device and liquid storage chamber connection hole 15, lower cover plate sealing groove 16 with nozzle, nozzle 17.

[0023] A constant magnetic field is generated outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com