Preparation and refining method of ethylene glycol mono-t-butyl ether

A technology of mono-tert-butyl ether and ethylene glycol, which is applied in the field of preparation and refining of ethylene glycol mono-tert-butyl ether, and can solve the problems of low ETB yield, low ETB selectivity, and high energy consumption for refining ethylene glycol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

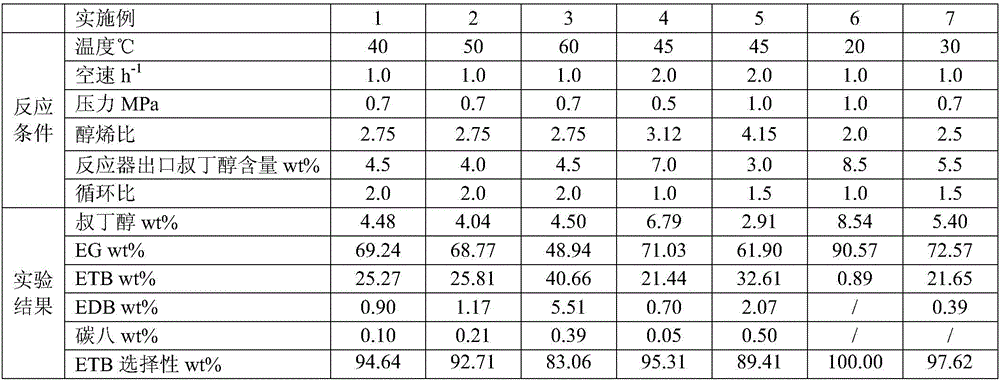

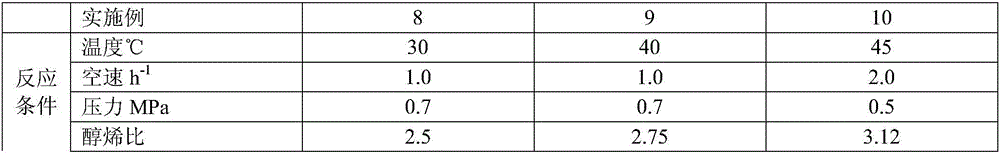

Examples

Embodiment Construction

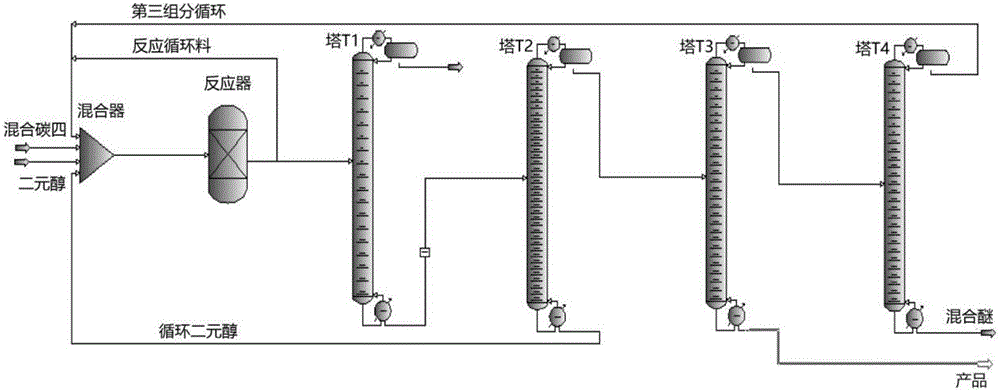

[0026] The invention provides a method for preparing ethylene glycol mono-tert-butyl ether. The method adopts ethylene glycol and mixed C4 as initial reaction materials in the presence of an acidic catalyst, and carries out the process in a reactor after adding tert-butanol and mixing. Etherification reaction, followed by separation and purification to obtain ethylene glycol mono-tert-butyl ether.

[0027] The reaction material mixture C4 of the present invention is a commonly used liquefied petroleum gas in petrochemical industry. The volume content of isobutene in the mixed C4 is 20-99.99%, and in some embodiments the volume content of the isobutene in the mixed C4 is 30-99.99%.

[0028] In some embodiments, the acidic catalyst is an acidic ion exchange resin, heteropolyacid, heteropolyacid salt or molecular sieve. Acidic ion exchange resins are preferred, and polystyrenesulfonic acid-based ion exchange resins are more preferred.

[0029] In some embodiments, in the starti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com