Static seal transmission type gate valve with bevel alloy seal and slag removal structures

A static sealing and transmission technology, applied in sliding valves, valve devices, engine components, etc., can solve the problems of high cost, short service life of imported valves, and leakage rate levels that do not meet the requirements of the national standard, so as to improve the sealing performance, The effect of preventing leakage of the valve and tightly fitting the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

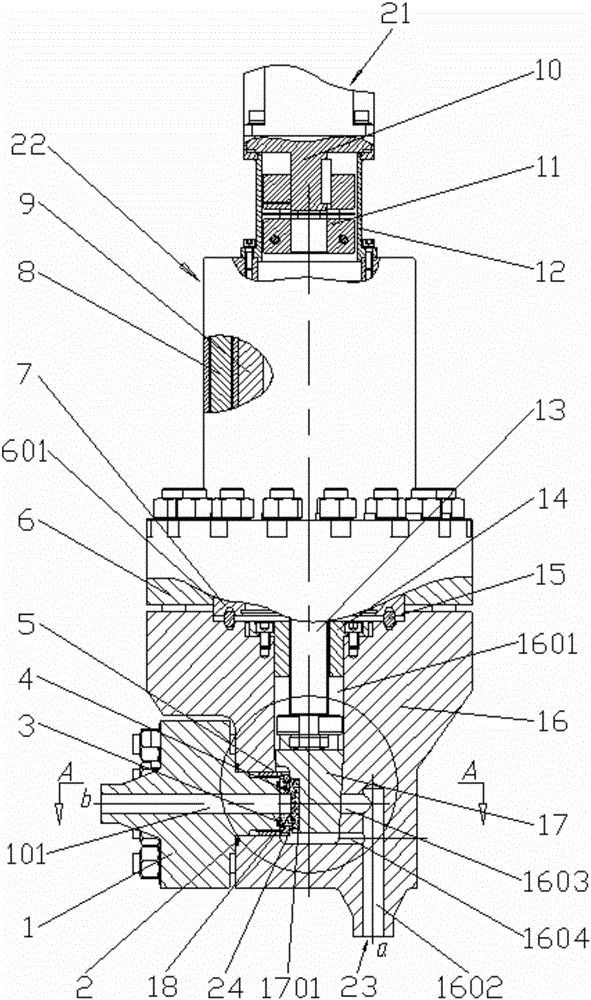

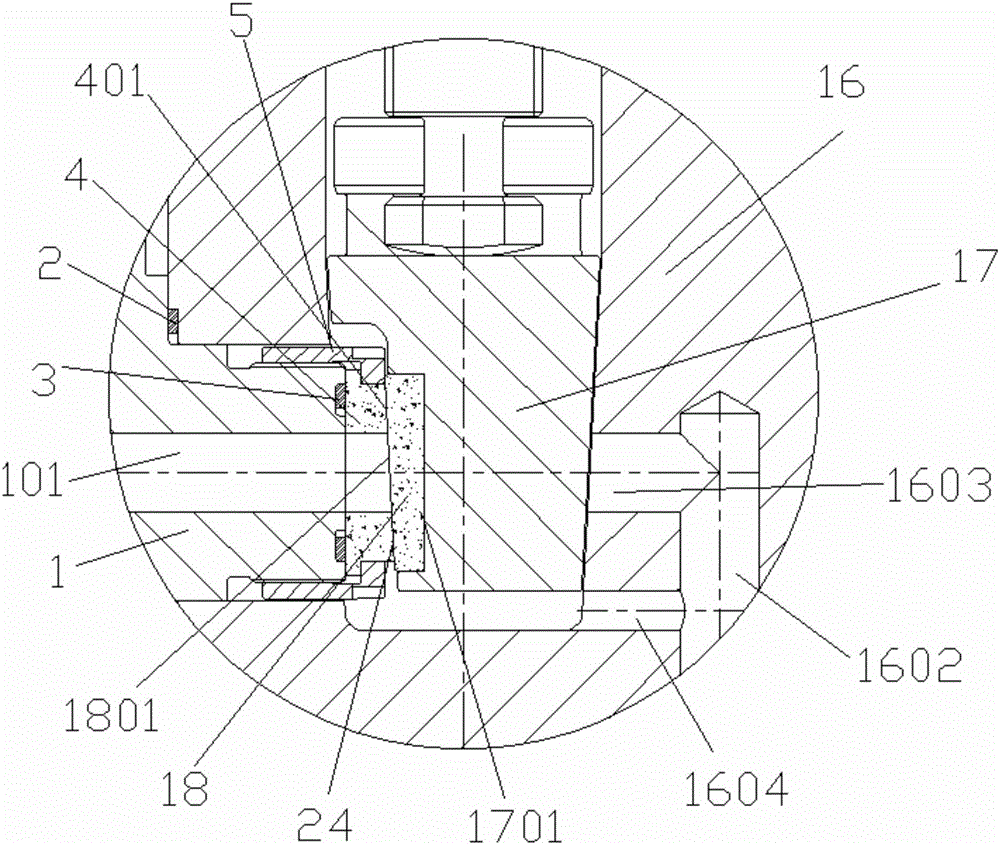

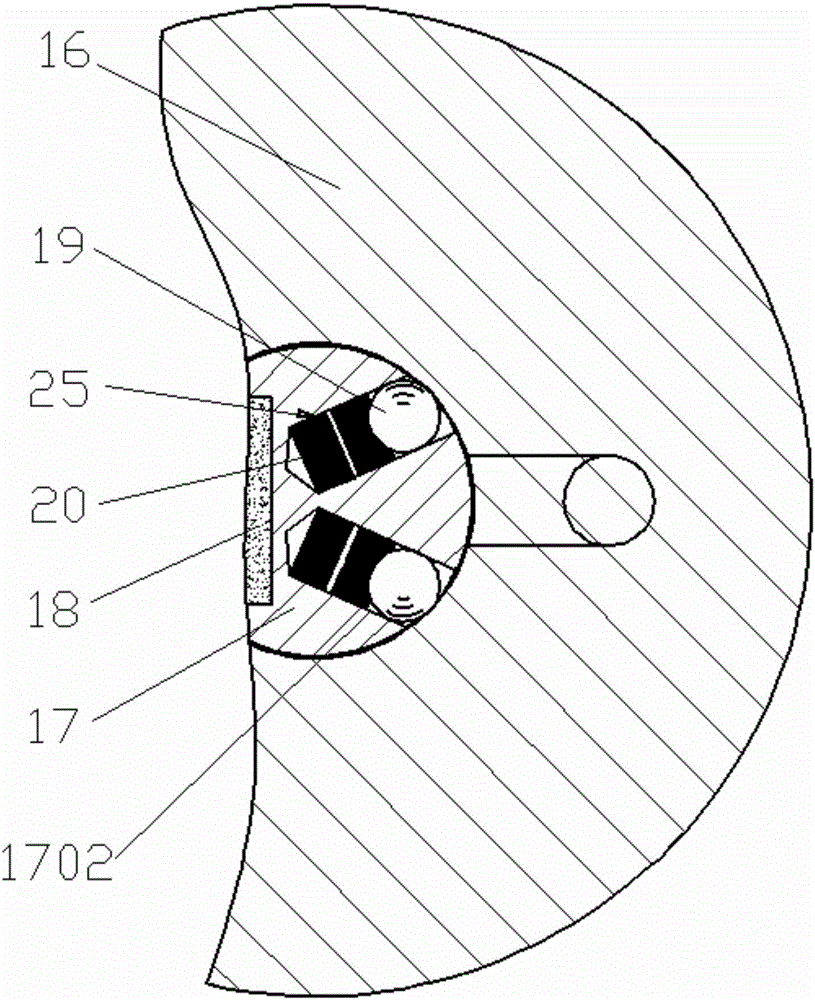

[0023] Attached below Figure 1-3 Embodiments of the present invention are described.

[0024] Static seal transmission gate valve with inclined plane alloy seal and slag cleaning structure, such as figure 1 As shown, it includes a power drive device 21 , a magnetic drive device 22 , a valve body 16 , a valve core 17 and a neck flange 1 .

[0025] The output end of the power drive device 21 is connected to the upper input end of the magnetic transmission device 22 . Specifically, such as figure 1 As shown, the power drive device 21 includes a motor 10, a shaft coupling 11 and a motor support 12, the motor support 12 plays a role in supporting the motor, and the upper end of the motor support 12 is connected to the motor 10 by a fastener. The housing is fixedly connected, the lower end of the motor support 12 is fixedly connected with the upper end of the magnetic transmission device 22 through fasteners, one end of the coupling 11 is fixedly connected with the power output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com