System and method of probe grinding and probe cleaning for testing probe oxidation

A technology for grinding needles, clearing needles, and testing probes, which can be applied to cleaning methods using gas flow, chemical instruments and methods, cleaning methods and utensils, etc., and can solve problems such as loss of service life of probe cards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

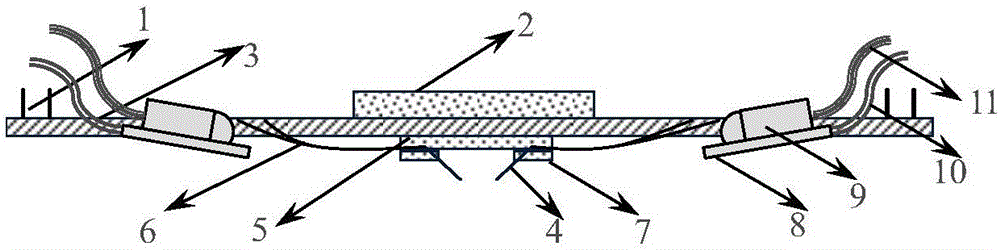

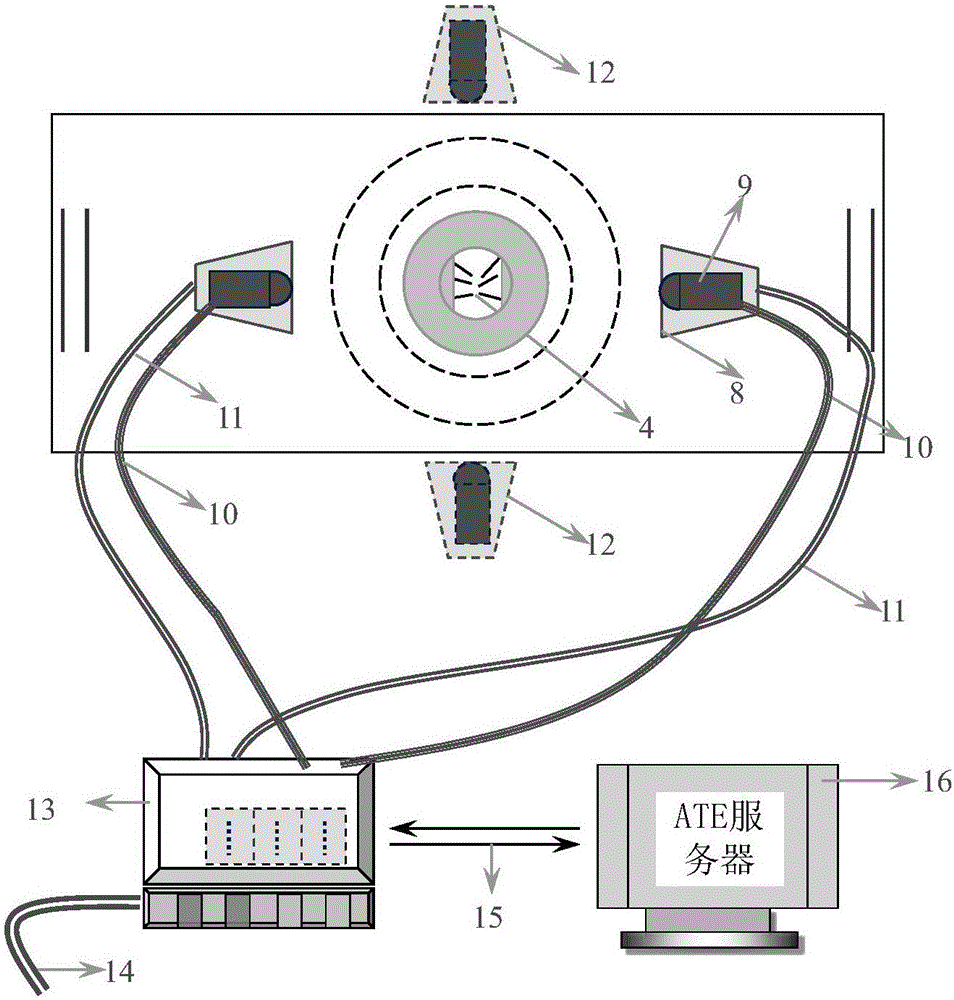

[0047] In order to solve the problems existing in the prior art, a needle grinding and needle cleaning system for testing the oxidation of probe card probes is provided, and the system includes:

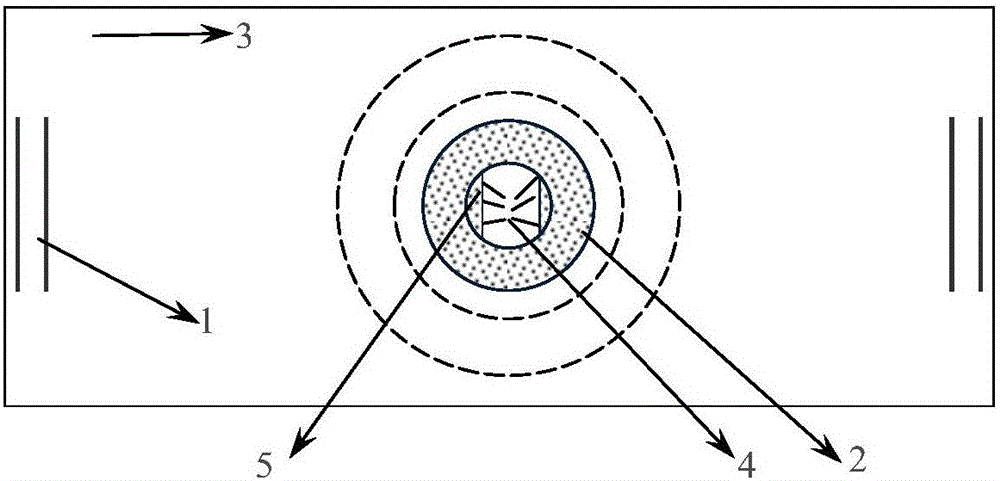

[0048] a probe testing unit, including a probe card and protruding probes disposed in the probe card, used for wafer testing;

[0049] The imaging analysis unit includes a plurality of imaging devices arranged on the probe card substrate, the imaging devices are aligned with the needle tips of the probes, and are used to image the probes and analyze the images of the probes. Grayscale analysis;

[0050] Needle grinding and needle cleaning unit, including needle grinding equipment and / or several gas cleaning equipment, wherein the gas cleaning equipment is facing the probe, and is used for spraying gas to remove the sundries on the probe;

[0051] a control unit, which communicates with the imaging analysis unit and the needle grinding needle cleaning unit respectively, and is used t...

Embodiment 2

[0073] The present invention also provides a needle grinding and needle cleaning method for testing the oxidation of probe card probes, the method comprising:

[0074] imaging the probe to obtain an image of the probe;

[0075] Analyzing the image to obtain the grayscale of the probe;

[0076] It is judged whether the grayscale is greater than a grayscale threshold, and when the grayscale of the probe is greater than the threshold, needle grinding and / or gas needle cleaning is performed on the probe.

[0077] Specifically, as Figure 5 As shown, the steps of analyzing the image to obtain the grayscale of the probe include:

[0078] adjusting the image and calculation area of the calibration probe tip;

[0079] The calculation weight of the grayscale of the probe tip is calibrated according to the current value passed by the chip pin;

[0080] Calculate the standard grayscale of the clean, unoxidized probe tip according to the weight;

[0081] Connect control COMS imagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com