Chopped pepper noodle as well as processing method and application thereof

A processing method and food processing technology, which is applied in the field of food processing, can solve the problems of thin taste, single raw material, and uncoordinated taste of slag spicy noodles, and achieve the effect of rich umami, improved nutritional value, and rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

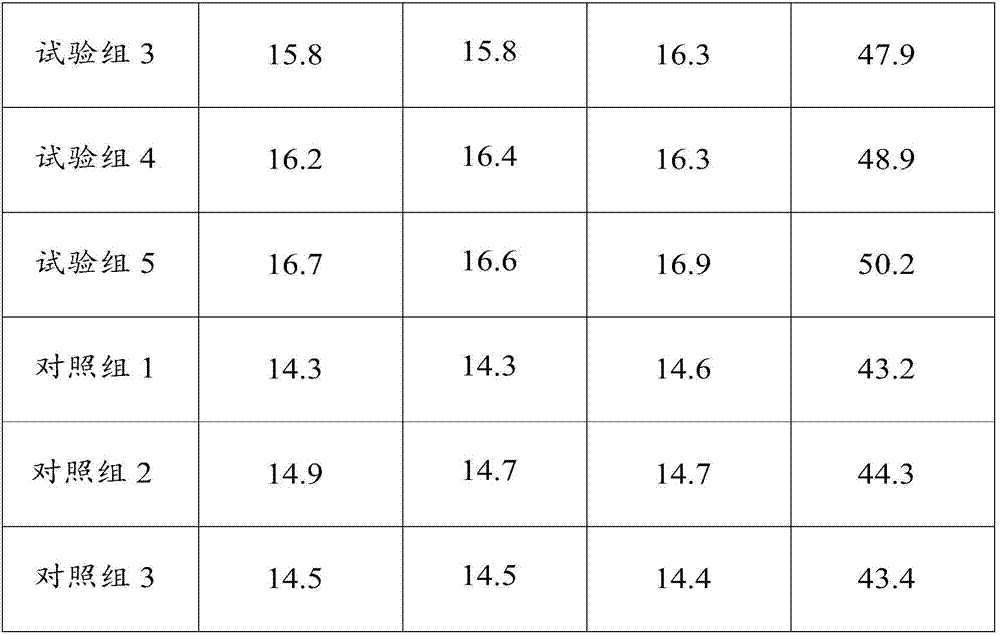

Embodiment 1

[0040] Eggshells and bones were crushed at 0°C to a particle size of 1 mm, and then crushed at -120°C to a particle size of 100 μm to obtain eggshell powder and bone powder.

[0041]Mix 12 parts by weight of pepper, 14 parts by weight of flour, 0.2 part by weight of 50-degree liquor and 0.7 part by weight of salt, and ferment for the first time at 15°C for 15 days. Then add 6 parts by weight of the above-mentioned eggshell powder, 8 parts by weight of the above-mentioned bone meal and 1 part by weight of vinegar, until the pH value of the fermentation system is 5, and then ferment for the second time for 25 days to obtain the spicy noodles.

[0042] The above-mentioned peppers are fresh long peppers with a length of 3.5 cm, and the flour contains glutinous rice flour and rice flour with a weight ratio of 1:0.7.

Embodiment 2

[0044] Eggshells and bones were crushed at 5°C to a particle size of 0.8 mm, and then crushed at -100°C to a particle size of 200 μm to obtain eggshell powder and bone powder.

[0045] Mix 18 parts by weight of pepper, 26 parts by weight of flour, 0.8 parts by weight of fruit wine and 1.3 parts by weight of salt, and ferment for the first time at 25° C. for 10 days. Then add 8 parts by weight of the above-mentioned eggshell powder, 10 parts by weight of the above-mentioned bone meal and 1.5 parts by weight of vinegar until the pH value of the fermentation system is 6, and then ferment for the second time for 15 days to obtain the spicy noodles.

[0046] The above-mentioned peppers are fresh long peppers with a length of 4 cm, and the flour contains glutinous rice flour and rice flour with a weight ratio of 1:1.2.

Embodiment 3

[0048] Eggshells and bones were crushed at 2.5°C to a particle size of 0.5 mm, and then at -110°C to a particle size of 150 μm to obtain eggshell powder and bone powder.

[0049] Mix 15 parts by weight of pepper, 20 parts by weight of flour, 0.5 part by weight of 60-degree liquor and 1 part by weight of salt, and ferment for the first time at 20°C for 13 days. Then add the above-mentioned eggshell powder of 7 parts by weight, the above-mentioned bone meal of 9 parts by weight and the vinegar of 1.2 parts by weight, until the pH value of the fermentation system is 5.5, ferment for the second time, and when the second fermentation ends, 20h to the fermentation Add 0.04 parts by weight of neutral protease to the system, and then continue the second fermentation until the second fermentation time is 20 days to obtain slag spicy noodles.

[0050] The above-mentioned peppers are fresh long peppers with a length of 3.8 cm, and the flour contains glutinous rice flour and rice flour wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com