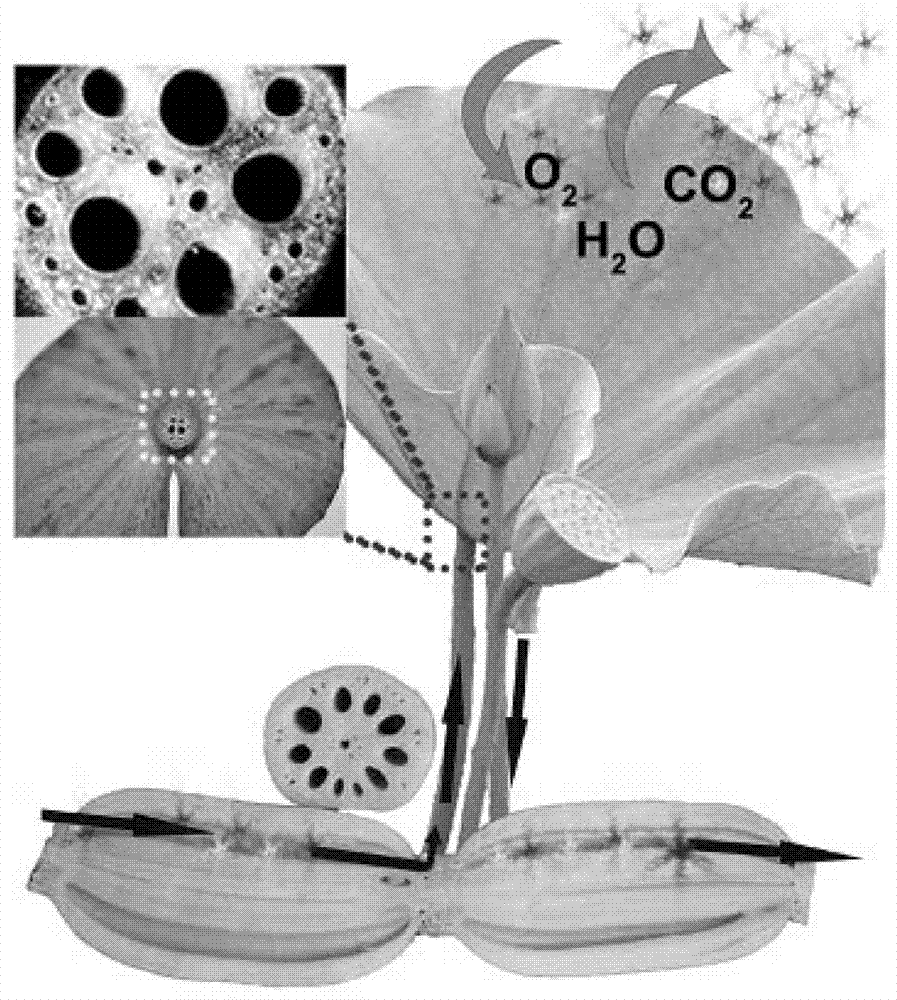

Bioactive bracket with bionic lotus-root structure, and preparation method and application thereof

A biologically active, bionic lotus root technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve problems such as low porosity, restriction of new blood vessels and new bone tissue growth, unfavorable nutrition and cell transmission, etc., to achieve improved Effect of Porosity and Specific Surface Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

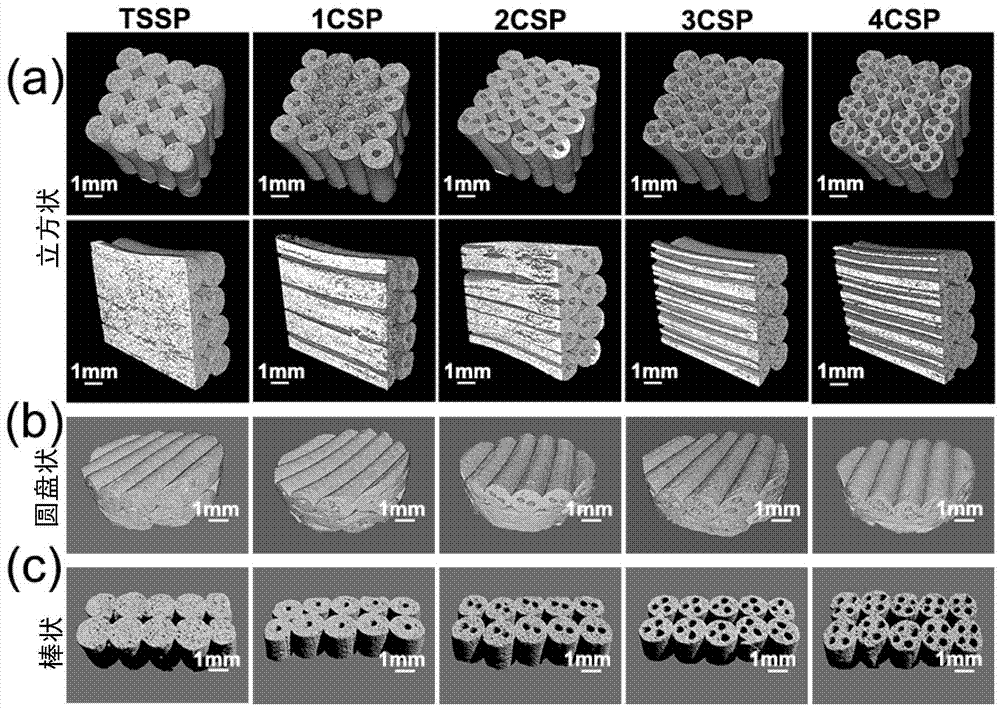

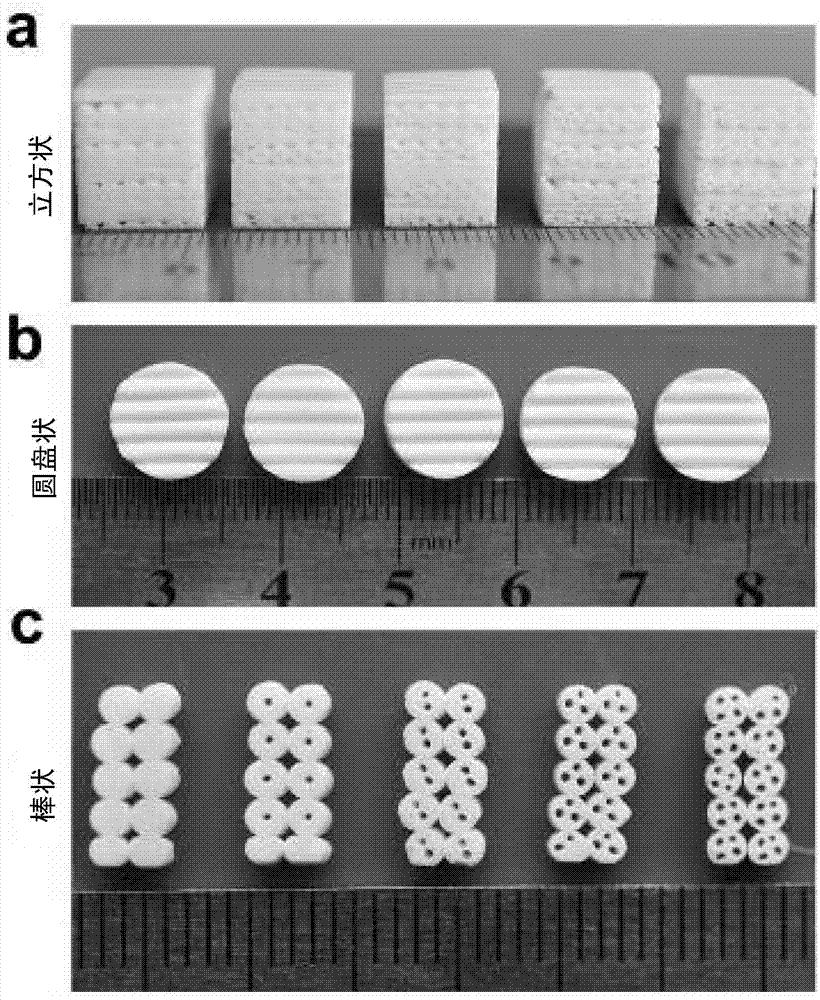

Embodiment 1 1

[0080] Embodiment 1 The preparation of one channel bionic lotus root support (1CSP) nozzle:

[0081] (1) A cylindrical steel needle with a diameter of 600 μm is embedded in parallel in the traditional No. 22 3D printing nozzle to ensure that the heads of the steel needle and the traditional nozzle do not touch each other and the distance is the same;

[0082] (2) 50g feldspar ceramic powder, 400 rpm planetary ball mill for 5 hours, the powder after ball milling was passed through 200 mesh sieve;

[0083] (3) Weighing 3.5g feldspar ceramic powder, 0.15g sodium alginate powder and 1.8g binder F127 (20wt%) are fully mixed to form a toothpaste-like slurry;

[0084] (4) Install the nozzle prepared in step 1, and print out a channel magnesian feldspar bionic lotus root support green body;

[0085] (5) The stent green body was sintered at 1350°C for 3 hours to obtain a one-channel biomimetic lotus root 3D printed stent.

Embodiment 2

[0086] The preparation of embodiment 2 dual-channel bionic lotus root support (2CSP) nozzle:

[0087] It is basically the same as Example 1, except that in step (1), two cylindrical steel needles with a diameter of 600 μm are embedded in parallel inside the traditional No. 22 3D printing nozzle, ensuring that the two steel needles and the head of the traditional nozzle are free touch each other and have the same spacing.

Embodiment 3 3

[0088] Embodiment 3 The preparation of the three-channel bionic lotus root support (3CSP) nozzle:

[0089] It is basically the same as Example 1, except that in step (1), three cylindrical steel needles with a diameter of 600 μm are inlaid in parallel inside the traditional No. 22 3D printing nozzle to ensure that the heads of the three steel needles and the traditional nozzle do not touch each other and the same spacing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com