Five-axis ultrasonic vibration numerical control machine tool for composite laser machining

A technology of laser processing and CNC machine tools, which is applied in the field of precision device processing, can solve problems such as the difficulty of precise control of laser size and shape, the difficulty of concentrating the distribution of energy density, and the change of material softening properties. Improve the accuracy of the shape and improve the effect of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

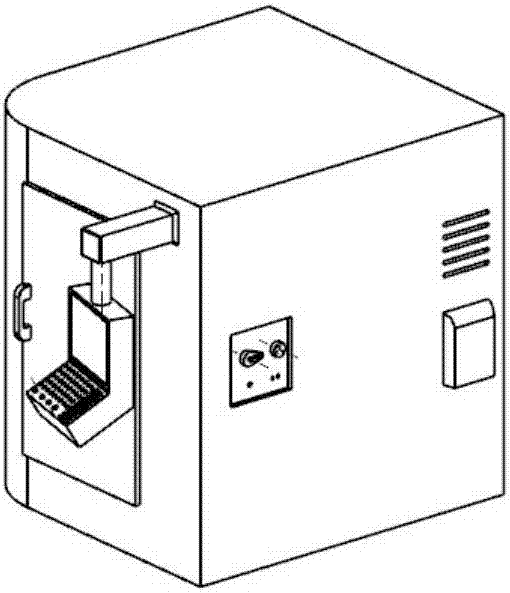

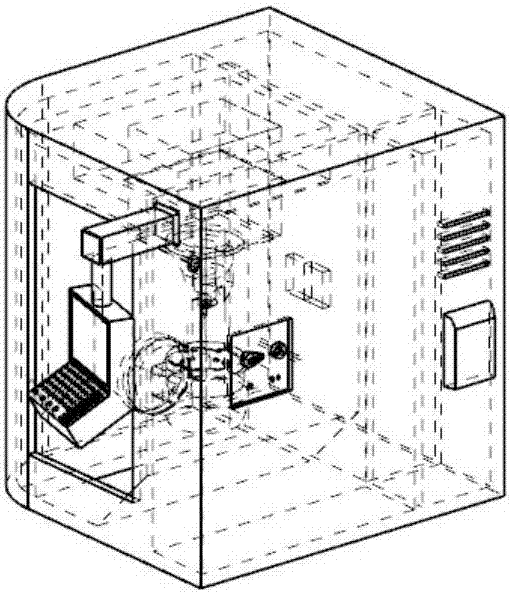

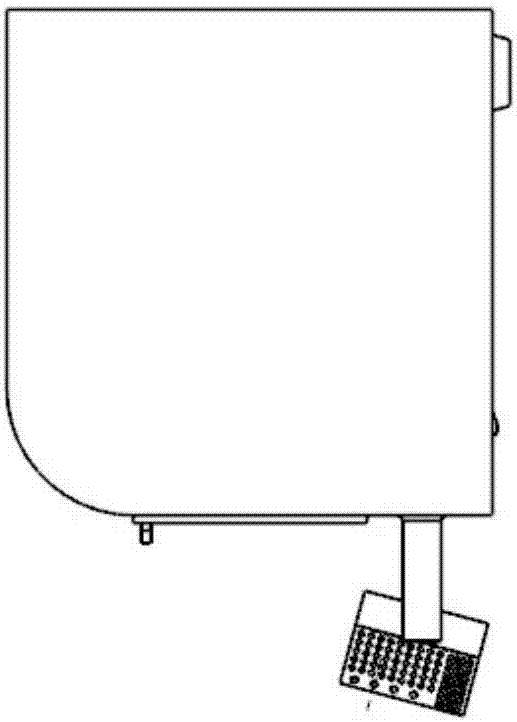

[0051] The five-axis ultrasonic vibroacoustic numerical control machine tool proposed by the present invention has the functions of mechanical processing and laser processing, such as Figures 1 to 6 shown. The ultrasonic machining is performed on the fixture of the machining tool. The tool setting has a high-frequency vibration in the vertical direction, and the frequency of the vibration of the tool head is controlled by a high-frequency changing current to achieve the processing of non-metallic materials. Performance parameters. Therefore, the CNC machine tool of the present invention can not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com