Ship bottom structure and fatigue life computing method thereof

A technology of bottom structure and fatigue life, which is applied in the field of ships, can solve the problems of increased ship structure weight, large fatigue life margin, conservative calculation structure, etc., and achieve the effect of reducing structure weight, improving construction efficiency, and reducing welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

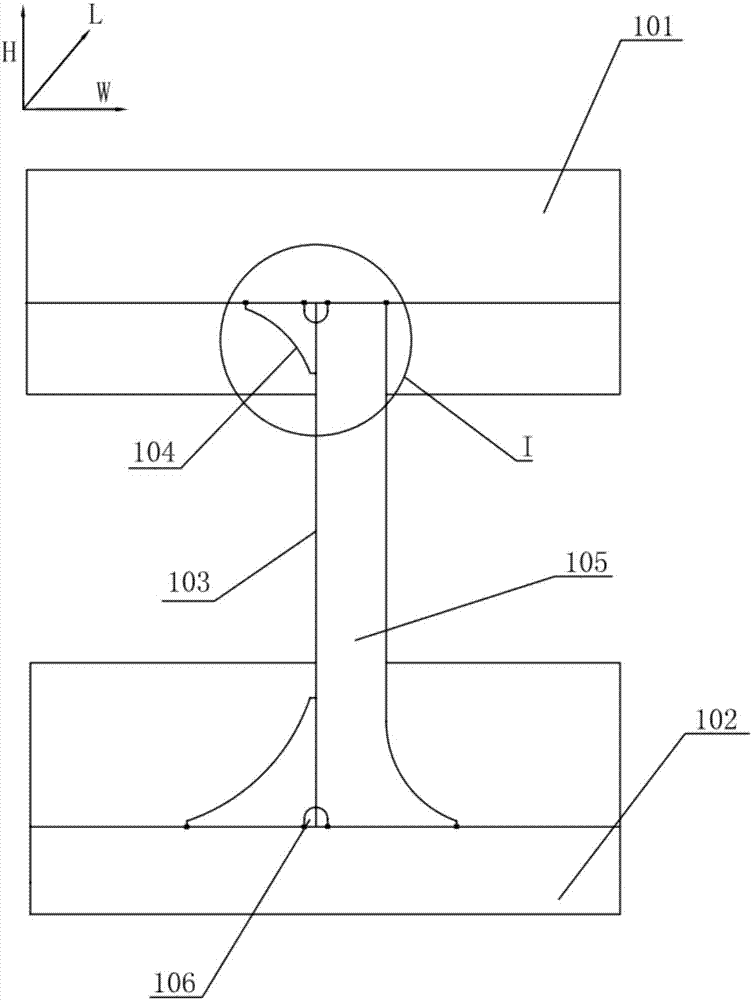

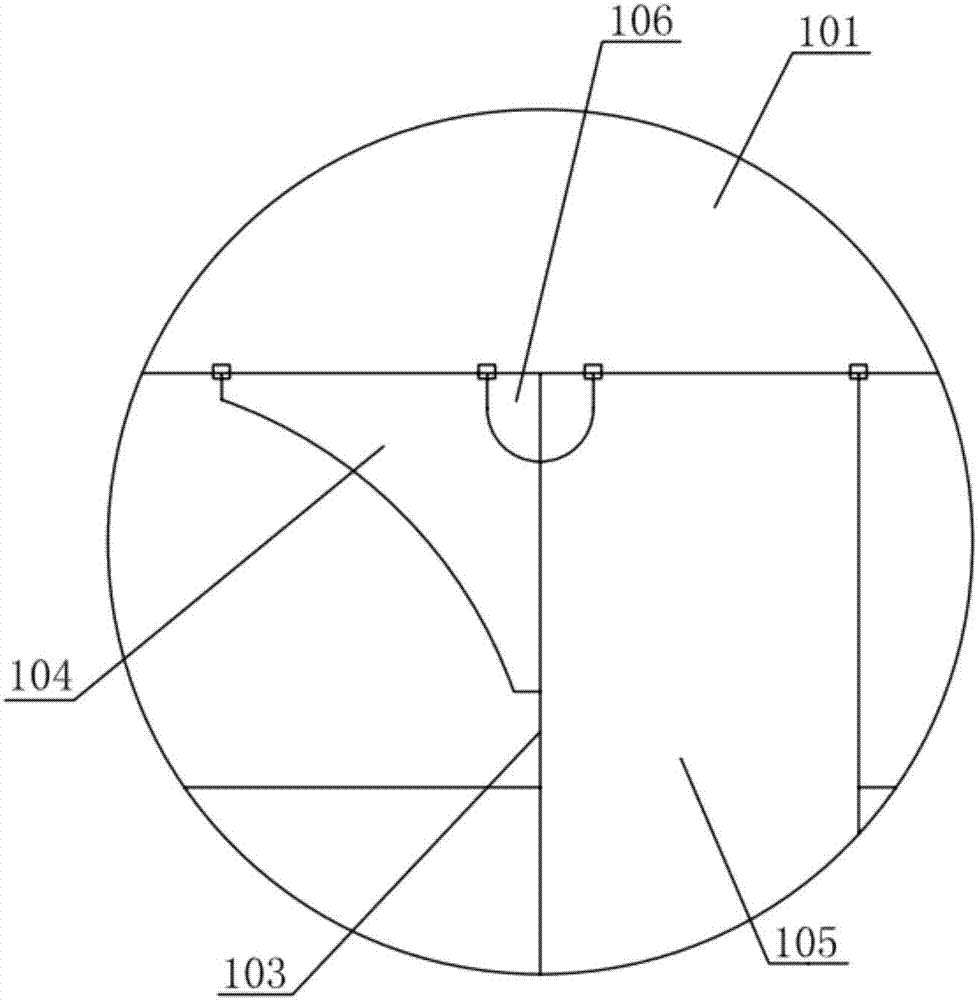

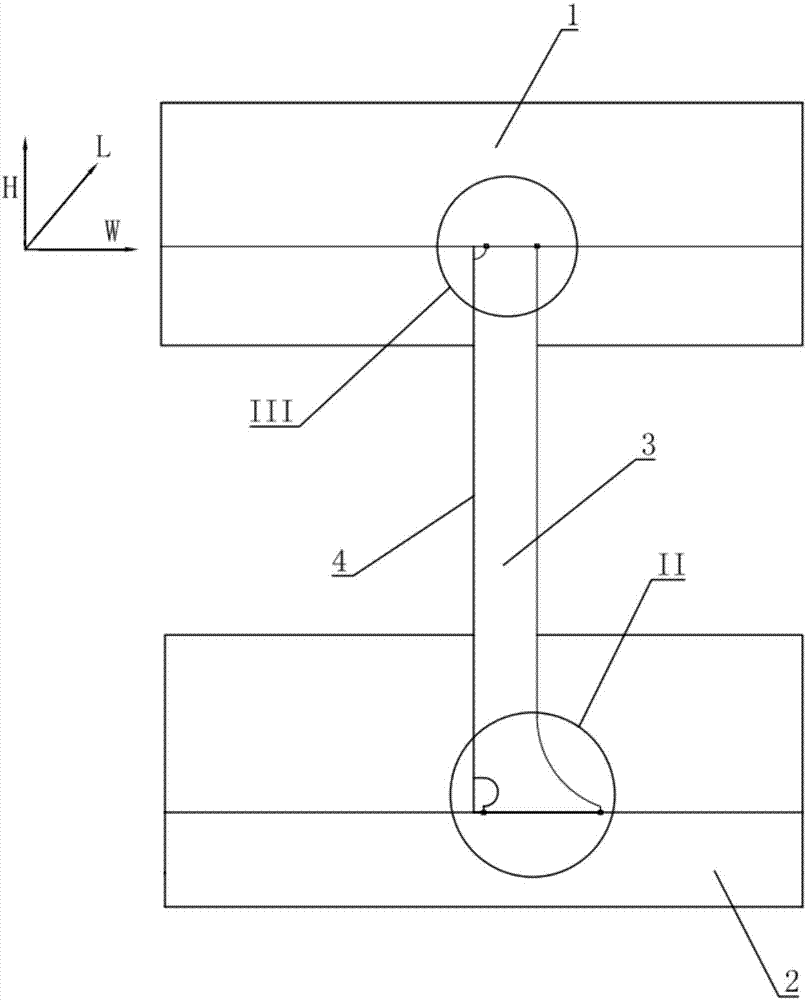

[0033] Such as image 3 As shown, the bottom structure of a ship in this embodiment includes an inner bottom longitudinal 1, an outer bottom longitudinal 2 arranged parallel to the inner bottom longitudinal 1, and a reinforcing rib 3 connecting the inner bottom longitudinal 1 and the outer bottom longitudinal 2 , and the rib plate 4 connected to one side of the rib 3, the height direction of the rib plate 4 ( image 3 The two ends in the direction shown in H) are respectively connected to the inner bottom longitudinal 1 and the outer bottom longitudinal 2, and the rib 4 is a flat plate.

[0034] Compared with the rib structure in the prior art, the rib 4 in this embodiment does not need to be provided with brackets, and the rib 4 in this embodiment can meet the requirements of the bottom structure of the ship on the inner bottom longitudinal 1 and the outer bottom longitudinal. The rigidity requirements of 2 reduce the structural weight, simplify the structural form, greatly ...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that several ribs 4 are provided along the length direction of the inner bottom longitudinal 101 , and the distance between two adjacent ribs 4 is equal. By increasing the number of ribs 4, the rigidity of the inner bottom longitudinal 1 and the outer bottom longitudinal 2 is increased, thereby prolonging the service life of the ship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com