Ice cream blank lifting transferring device

A conveying device and ice cream technology, applied in conveyors, transportation and packaging, etc., can solve problems such as body breakage, shape deformation, falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

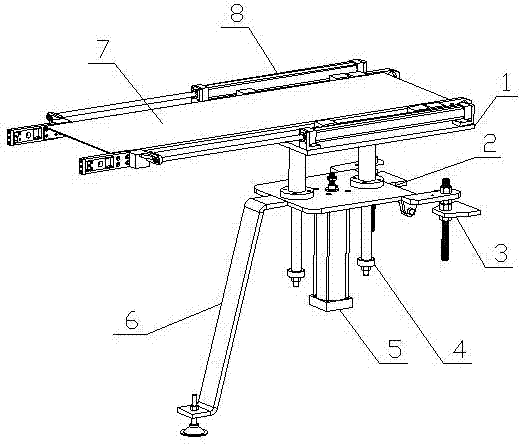

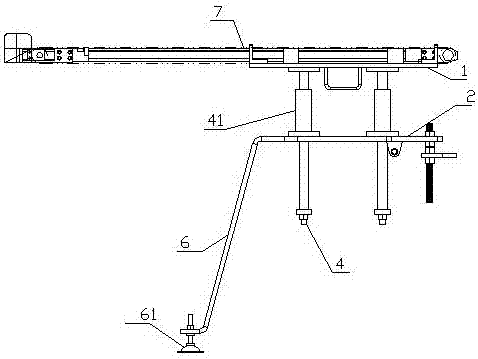

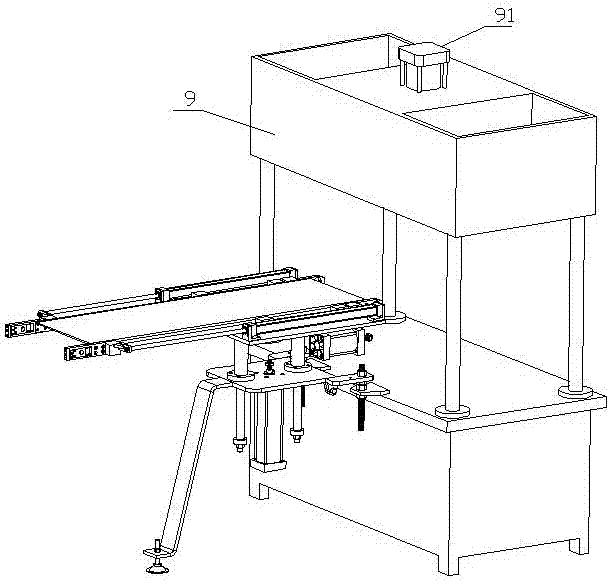

[0016] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of ice cream body lifting conveying device, comprises the conveying device that is connected with the frame of green body forming machine 9, is provided with extruding extrusion cylinder 91 that is used for extruding above the mold, is used for raw material according to the mould. Shape extrusion. Wherein the transmission device is arranged in layers up and down, and the lower part is a horizontal fixed platform 2, one side of the fixed platform is connected with the green body forming machine, and the other side is connected with the outriggers, and the outriggers are supported by the ground to play a stable role. The middle part of the fixed platform is provided with a vertical telescopic device 5, which adopts an air cylinder or a hydraulic cylinder as the telescopic device, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com