Digital direct-injecting eco-solvent double-sided printing advertisement cloth and preparation process thereof

A double-sided printing and digital direct-injection technology, applied in the field of advertising cloth, can solve the problems of non-degradable, poor flame-retardant performance, and non-folding, etc., and achieve good softness and wrinkle resistance, good flame-retardant performance, and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

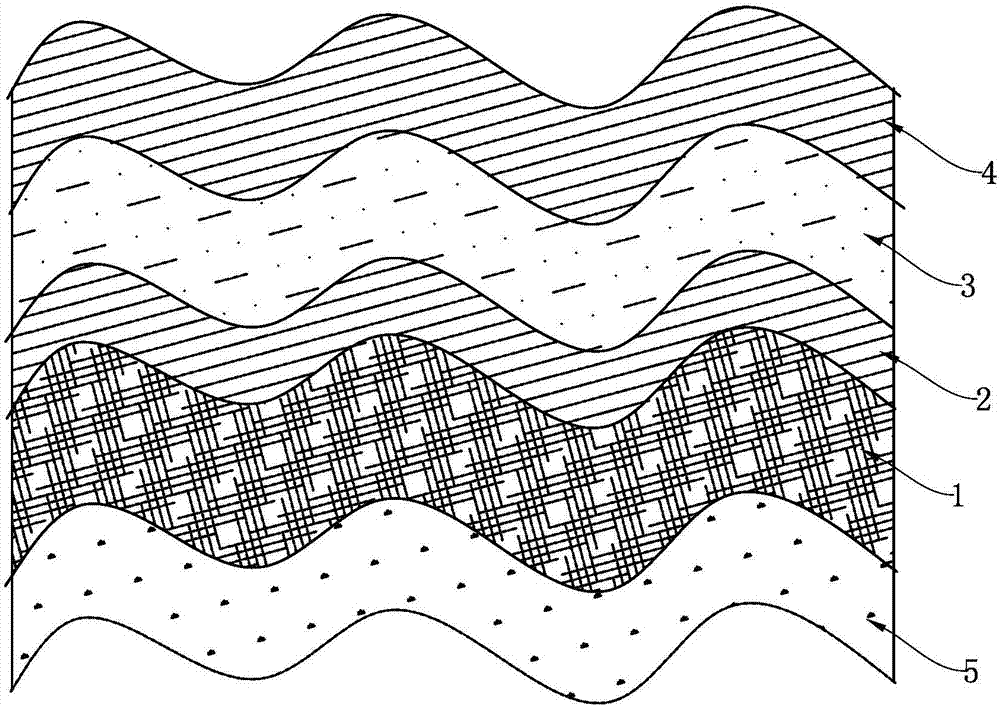

[0035] A digital direct-injection weak solvent double-sided printing advertising cloth, such as figure 1 As shown, it includes polyester chemical fiber cloth layer 1, one side of polyester chemical fiber cloth layer 1 is provided with whitening waterproof coating 2, the surface of whitening waterproof coating 2 is provided with composite flame-retardant coating 3, and the surface of composite flame-retardant coating 3 An eco-solvent ink-absorbing coating 4 is provided on the surface, and a sublimation ink-absorbing coating 5 is provided on the other side of the polyester chemical fiber cloth layer 1 . The coating amount of the whitening waterproof coating 2 is 40-50gsm; the coating amount of the composite flame-retardant coating 3 is 40-50gsm; the coating amount of the weak solvent ink absorbing coating 4 is 20-30gsm; the sublimation ink The absorber coating 5 was applied in a weight of 40-50 gsm.

[0036] Wherein the whitening and waterproof coating 2 is a compound coating o...

Embodiment 2

[0049] A digital direct-injection weak solvent double-sided printing advertising cloth, such as figure 1 As shown, it includes polyester chemical fiber cloth layer 1, one side of polyester chemical fiber cloth layer 1 is provided with whitening waterproof coating 2, the surface of whitening waterproof coating 2 is provided with composite flame-retardant coating 3, and the surface of composite flame-retardant coating 3 An eco-solvent ink-absorbing coating 4 is provided on the surface, and a sublimation ink-absorbing coating 5 is provided on the other side of the polyester chemical fiber cloth layer 1 . Wherein the whitening waterproof coating 2 is a coating formed by compound coating of a whitening agent, a waterproofing agent and a thickener on the surface of the polyester chemical fiber cloth layer 1;

[0050] Eco-solvent ink-absorbing coating 4 is a coating formed by composite coating of water-based polyacrylic acid emulsion, polyethylene wax, silicon dioxide, inorganic fill...

Embodiment 3

[0062] A digital direct-injection weak solvent double-sided printing advertising cloth, such as figure 1 As shown, it includes polyester chemical fiber cloth layer 1, one side of polyester chemical fiber cloth layer 1 is provided with whitening waterproof coating 2, the surface of whitening waterproof coating 2 is provided with composite flame-retardant coating 3, and the surface of composite flame-retardant coating 3 An eco-solvent ink-absorbing coating 4 is provided on the surface, and a sublimation ink-absorbing coating 5 is provided on the other side of the polyester chemical fiber cloth layer 1 . Wherein the whitening waterproof coating 2 is a coating formed by compound coating of a whitening agent, a waterproofing agent and a thickener on the surface of the polyester chemical fiber cloth layer 1;

[0063] Eco-solvent ink-absorbing coating 4 is a coating formed by composite coating of water-based polyacrylic acid emulsion, polyethylene wax, silicon dioxide, inorganic fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com