Labor-saving testing equipment for integrated circuit boards

A technology for integrated circuit boards and testing equipment, applied in electronic circuit testing, components of electrical measuring instruments, measuring electricity, etc., can solve the problems of inconvenient access, laborious operation, and low efficiency of the aging test seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

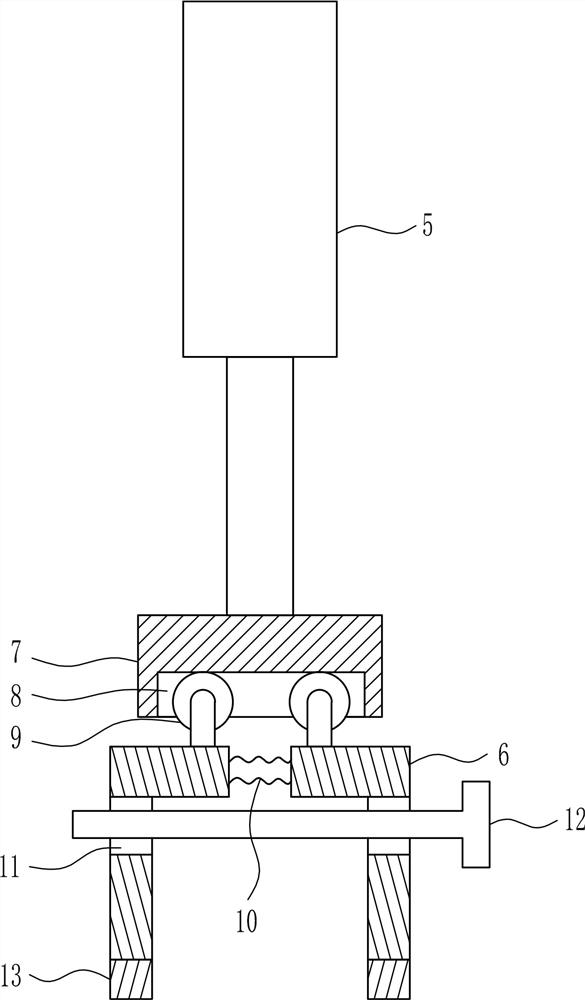

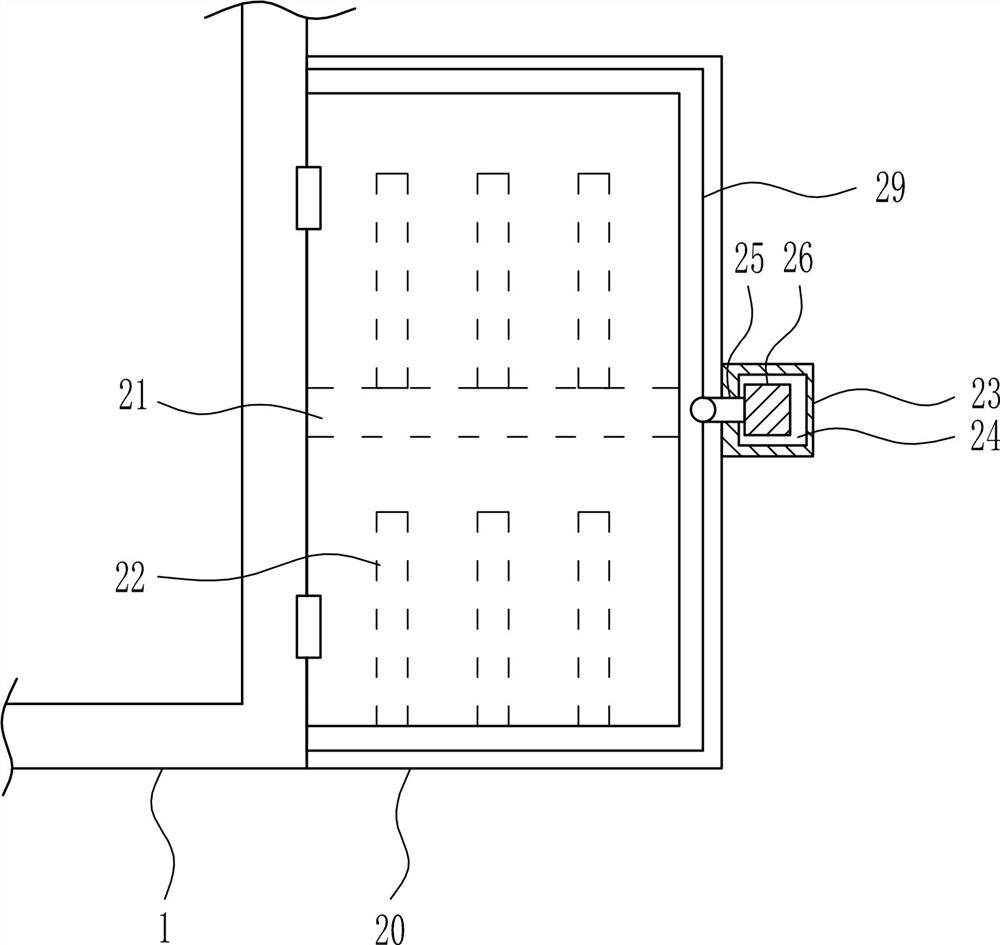

[0036]A labor-saving test equipment for integrated circuit boards, such asFigure 1-7As shown, it includes a bracket 1, a test seat 2, a lifting mechanism 3, a moving mechanism 4, an air cylinder 5, a first pressing rod 6, a first slide rail 27, and a first sliding block 28. The upper part of the bottom of the bracket 1 is evenly connected with a test Seat 2, the left side of the bracket 1 is provided with a lifting mechanism 3, the upper part of the bracket 1 is symmetrically connected with a first slide rail 27, and the first slide rail 27 is slidably connected with a first sliding block 28, the first sliding block 28 Cooperating with the first slide rail 27, a moving mechanism 4 is connected between the first sliding blocks 28 on the left and right sides. The bottom of the moving mechanism 4 is provided with air cylinders 5 on both front and rear sides, and the bottom of the air cylinder 5 is connected with a first pressure rod. 6.

Embodiment 2

[0038]A labor-saving test equipment for integrated circuit boards, such asFigure 1-7As shown, it includes a bracket 1, a test seat 2, a lifting mechanism 3, a moving mechanism 4, an air cylinder 5, a first pressing rod 6, a first slide rail 27, and a first sliding block 28. The upper part of the bottom of the bracket 1 is evenly connected with a test Seat 2, the left side of the bracket 1 is provided with a lifting mechanism 3, the upper part of the bracket 1 is symmetrically connected with a first slide rail 27, and the first slide rail 27 is slidably connected with a first sliding block 28, the first sliding block 28 Cooperating with the first slide rail 27, a moving mechanism 4 is connected between the first sliding blocks 28 on the left and right sides. The bottom of the moving mechanism 4 is provided with air cylinders 5 on both front and rear sides, and the bottom of the air cylinder 5 is connected with a first pressure rod. 6.

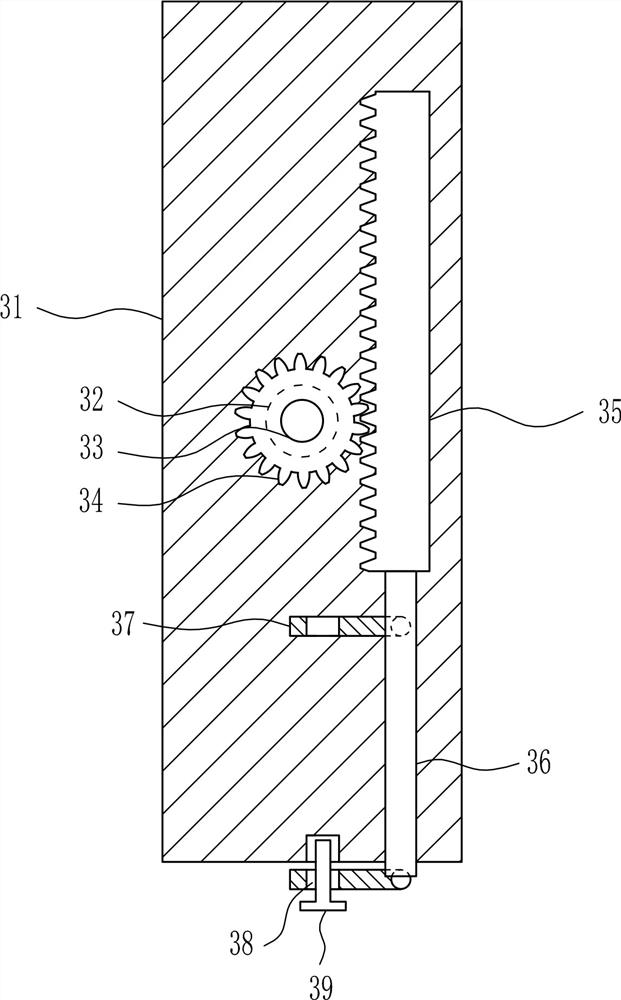

[0039]The lifting mechanism 3 includes a mounting ...

Embodiment 3

[0041]A labor-saving test equipment for integrated circuit boards, such asFigure 1-7As shown, it includes a bracket 1, a test seat 2, a lifting mechanism 3, a moving mechanism 4, an air cylinder 5, a first pressing rod 6, a first slide rail 27, and a first sliding block 28. The upper part of the bottom of the bracket 1 is evenly connected with a test Seat 2, the left side of the bracket 1 is provided with a lifting mechanism 3, the upper part of the bracket 1 is symmetrically connected with a first slide rail 27, and the first slide rail 27 is slidably connected with a first sliding block 28, the first sliding block 28 Cooperating with the first slide rail 27, a moving mechanism 4 is connected between the first sliding blocks 28 on the left and right sides. The bottom of the moving mechanism 4 is provided with air cylinders 5 on both front and rear sides, and the bottom of the air cylinder 5 is connected with a first pressure rod. 6.

[0042]The lifting mechanism 3 includes a mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com