Numerical control machine tool cutting speed optimization method

A technology of cutting speed and optimization method, which is applied in the field of CNC machine tools to achieve the effects of easy installation, optimized cutting speed and extended tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

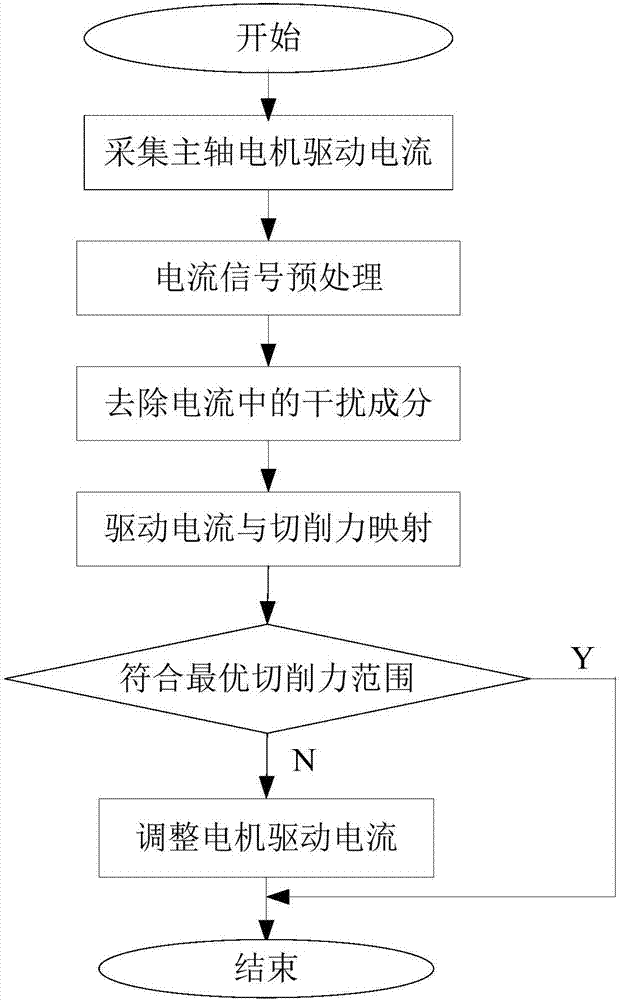

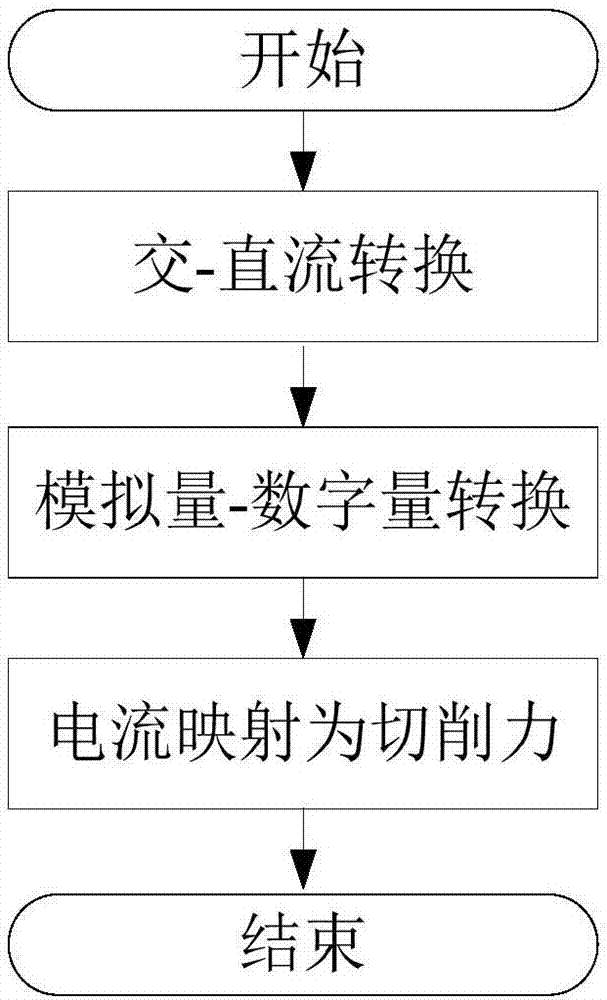

[0021] A cutting speed optimization method for CNC machine tools, such as figure 1 As shown, it is a system flowchart of a cutting speed optimization method for CNC machine tools, which mainly includes the following three steps:

[0022] Step 1: Periodically collect the relevant parameters of the spindle motor of the CNC machine tool, including the drive current of the spindle motor and the power of the spindle motor; the drive current of the spindle motor is collected periodically through the Hall current sensor, and the power of the spindle motor is directly read from the inverter;

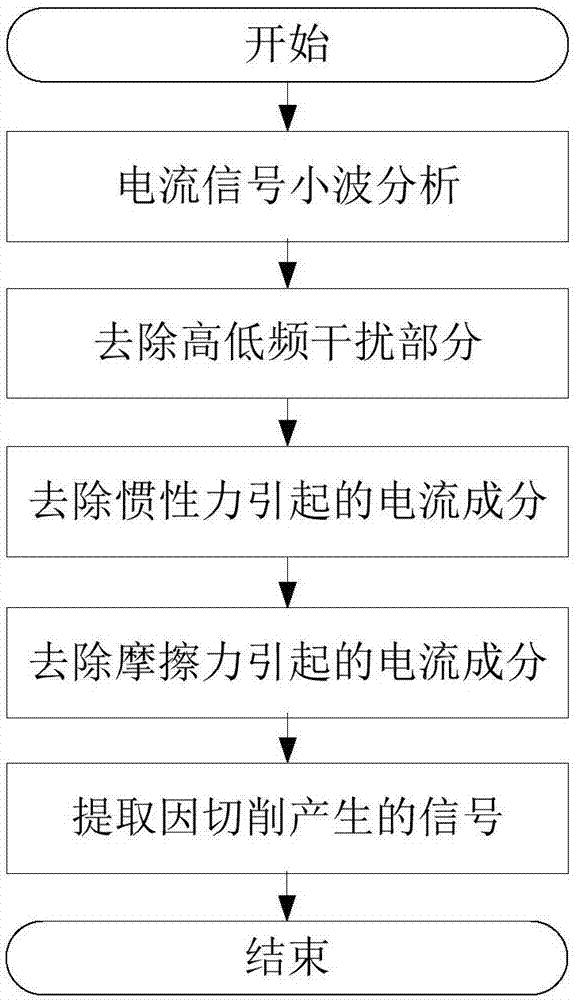

[0023] Step 2: Perform wavelet decomposition on the collected current signal to determine the interference components existing in the original current signal. Such as figure 2 Shown is the flow chart of the spindle motor current analysis and interference removal in the present invention.

[0024] Define the Morlet wavelet function sequence as

[0025] ψ a,b (t)=a -1 / 2 ψ((t-b) / a), a∈R, a>0,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com