Multi-scale calculation method for equivalent thermal expansion coefficient of complicated composite material structure

A composite material and expansion coefficient technology, which is applied in calculation, electrical digital data processing, design optimization/simulation, etc., can solve problems such as software not being disclosed to the public, affecting macroscopic material performance, and limiting engineering applications, etc., to achieve good accuracy and good performance. Applicability, effect of promoting application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

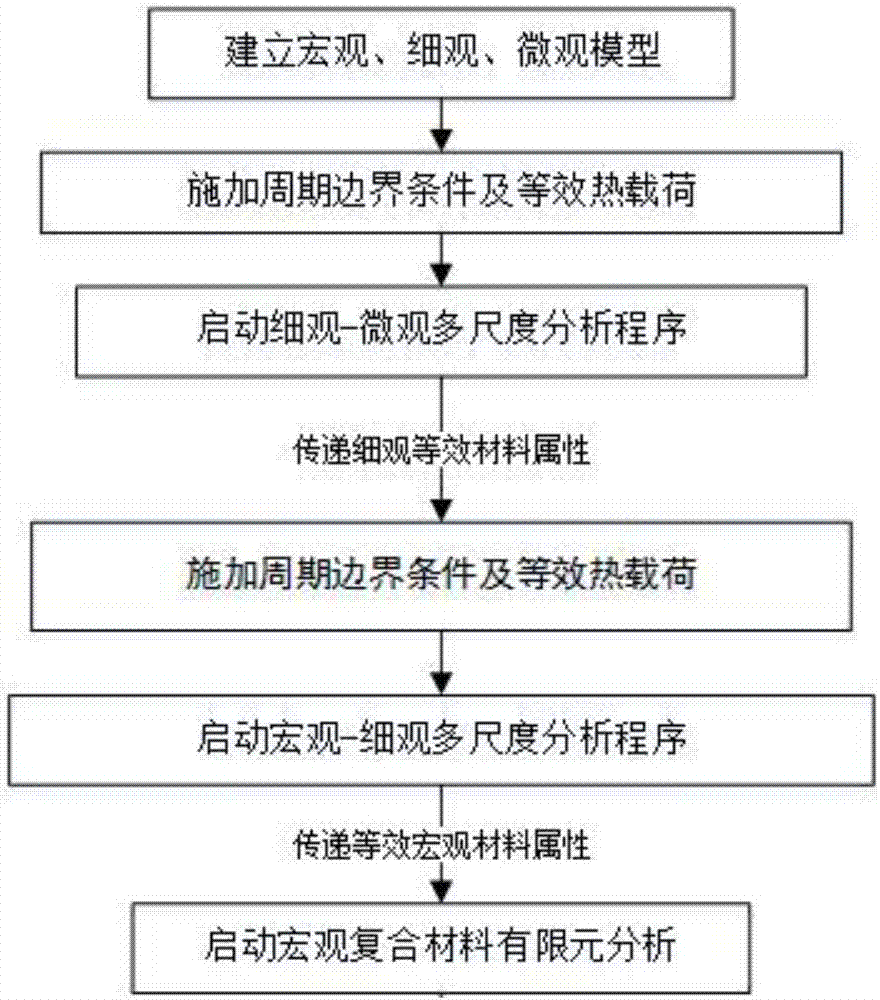

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0041] This embodiment takes the equivalent material performance calculation of a certain type of pressure vessel as an example, implements it according to the technical solution of the present invention, and gives a detailed implementation process.

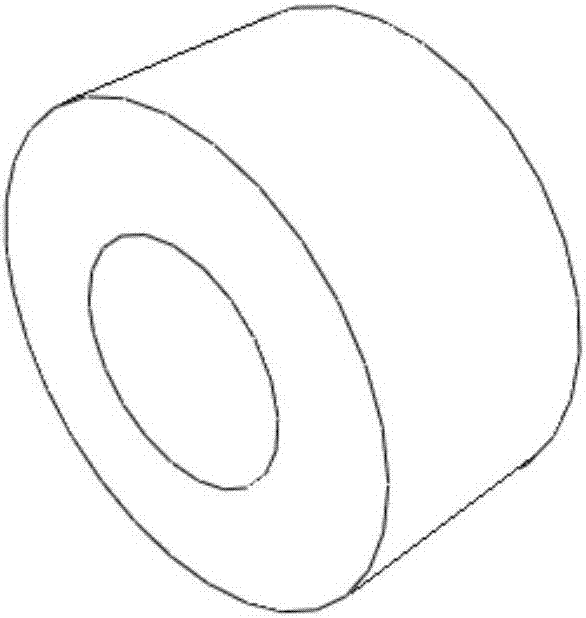

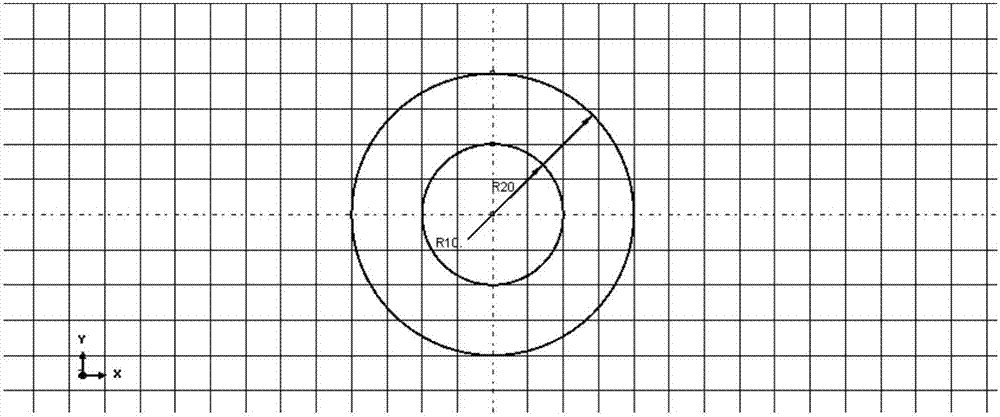

[0042] Step 1: The pressure vessel is made of carbon / carbon composite materials, and the prefabricated body of the mesoscopic structure is composed of no weft cloth, ±45° lay-up, 0°, and 90° lay-up. According to the actual size of the example, such as figure 2 and image 3 As shown, the cylinder is 20mm long. The macroscopic finite element analysis model of the pressure vessel is established in the commercial finite element software ABAQUS, and the material coordinate system of the macroscopic finite element a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com