Composite Magnetic Sealing Material

A sealing material and composite magnetic technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of mold material interface peeling, electronic components or mold material cracks, etc., and achieve the effect of small thermal expansion coefficient and warpage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083]

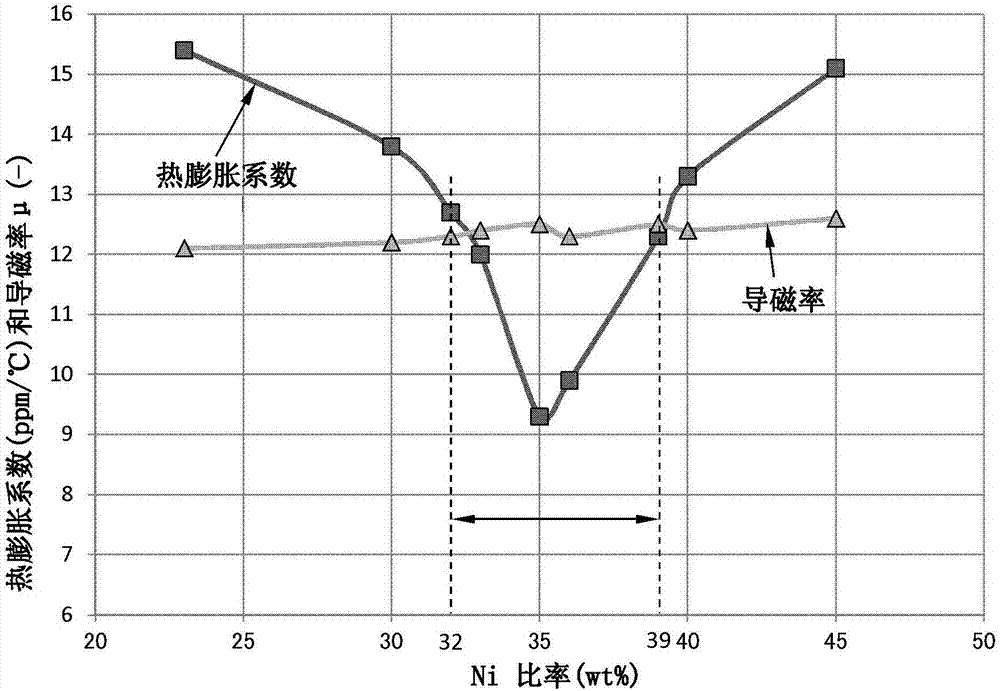

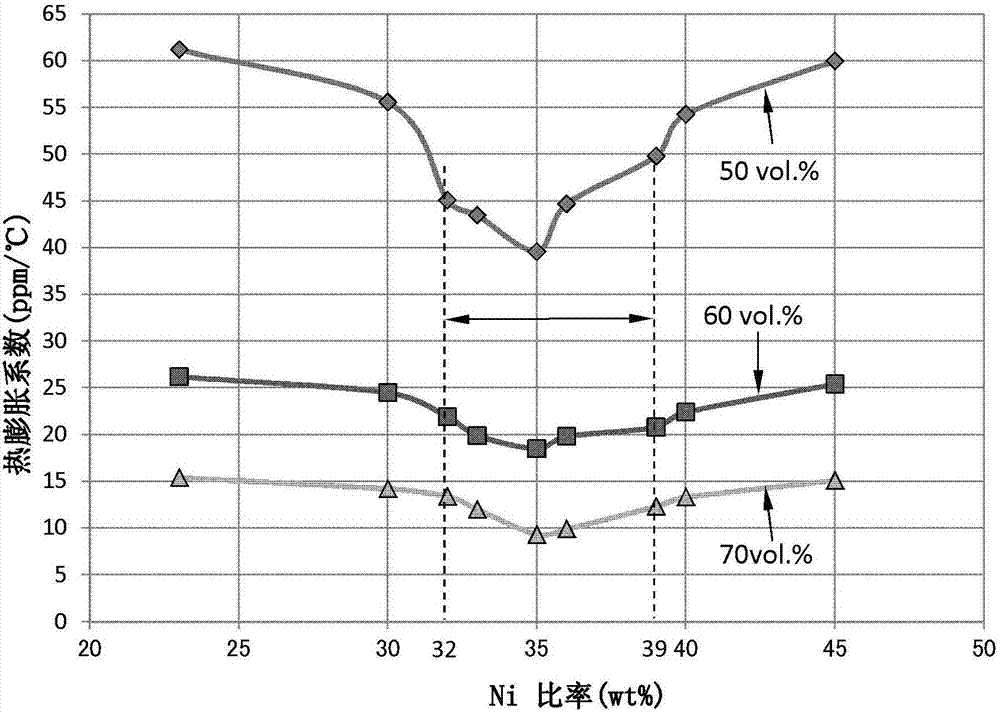

[0084] Resin materials were prepared by using the following preparations, that is, as the main ingredient, 830S (bisphenol A type epoxy resin) manufactured by DIC Corporation was used, and as the curing agent, 0.5 equivalents of Nippon Carbide Industries Co., DicyDD (dicyandiamide dicyandiamide) manufactured by Inc. used C11Z-CN (Imidazole imidazole) manufactured by Shikoku Chemical Industry Co., Ltd. (Japan) at 1 wt% as a curing accelerator relative to the main ingredient. 50% by volume, 70% by volume, or 70% by volume of Figure 17 The magnetic filler of the indicated composition was added to the above-mentioned resin material, and thoroughly kneaded to obtain a paste. Also, when it is not possible to make a paste, diethylene glycol butyl ether acetate (butyl carbitol acetate) is added at an appropriate time. This paste was applied to a thickness of approximately 300 μm, and thermally cured in the order of 100° C. for 1 hour, 130° C. for 1 hour, 150° C. for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com