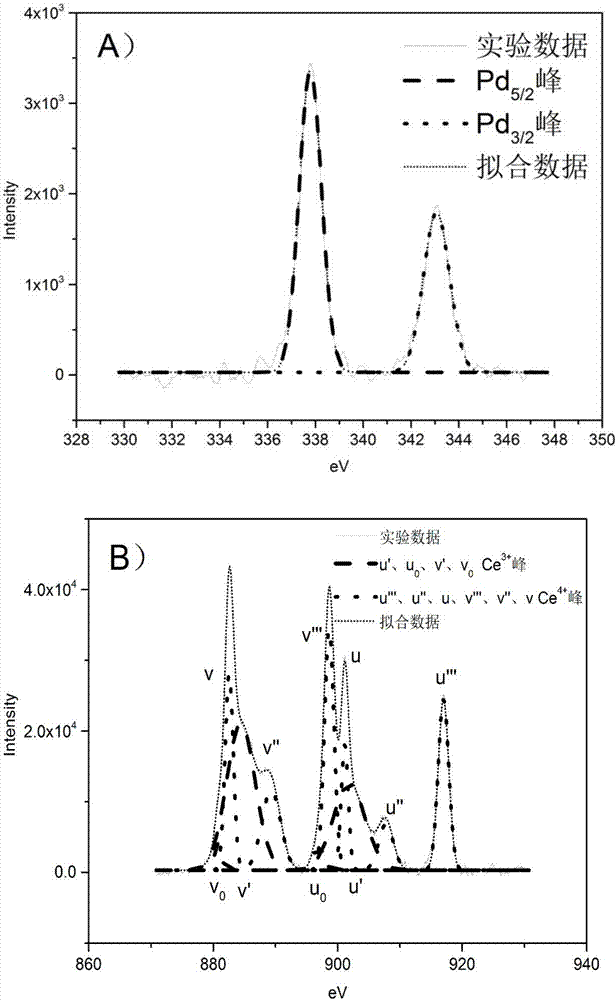

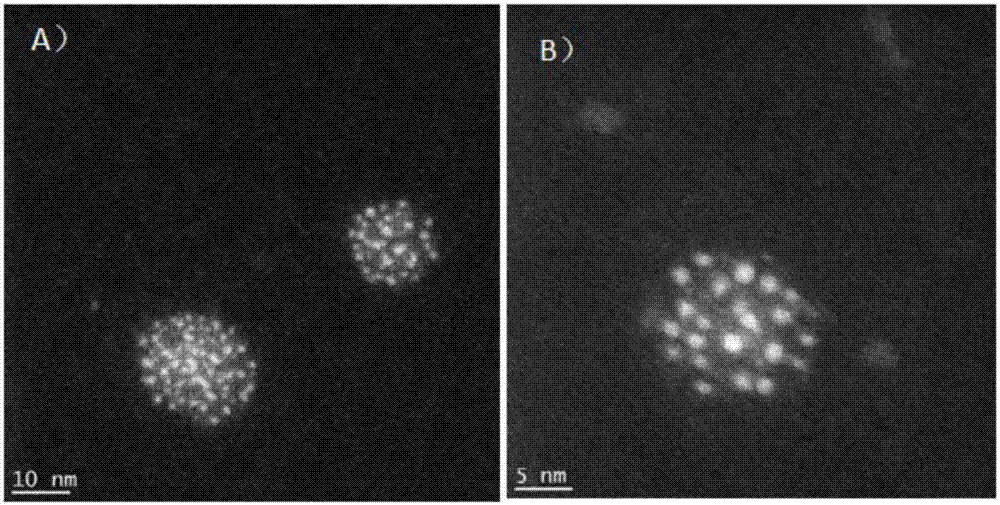

Supported palladium catalyst using palladium oxide as support and preparation method thereof

A technology of supported palladium and cerium oxide, which is applied in the field of supported palladium catalyst and its preparation, can solve the problems of inconsistent particle size, failure to obtain catalytic effect, uneven dispersion of Pd particles, etc., and achieve improved utilization rate and good low-temperature oxidation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of palladium solution: the measured concentration is 1.88×10 ‐7 mol / L palladium nitrate solution 0.5ml, dilute to 32ml with deionized water, stir evenly while adding, keep the rotation speed at a low speed to ensure even stirring. Take by weighing 19.6g sodium hydroxide solid, pour into it slowly, increase stirring speed, guarantee to dissolve rapidly. After complete dissolution, a yellow viscous palladium solution was obtained, and the temperature was lowered to 20°C.

[0026] (2) Preparation of cerium oxide colloid: Measure 5ml of cerium nitrate solution with a concentration of 1.16mol / L, dilute it to 32ml with deionized water, stir evenly while adding, and keep the rotating speed at a low speed to ensure uniform stirring. Take by weighing 19.6g sodium hydroxide solid, slowly pour into wherein to form precipitation. Cool down and stir for 30 min to form a uniform white colloidal solution and keep the temperature at 20°C.

[0027](3) Preparation of P...

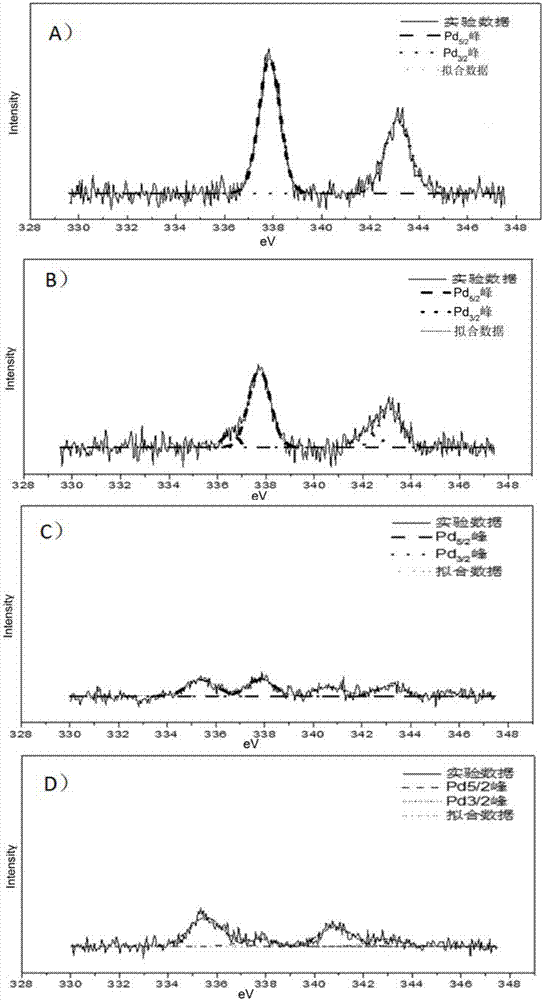

Embodiment 2~4

[0029] The preparation method of Examples 2 to 4 is the same as that of Example 1, except that the reaction temperature during step (3) loading is changed to 40°C, 60°C, and 80°C respectively.

Embodiment 5

[0031] (1) Preparation of palladium solution: the measured concentration is 3.76×10 ‐7 mol / L palladium nitrate solution 0.5ml, dilute to 32ml with deionized water, stir evenly while adding, keep the rotation speed at a low speed to ensure even stirring. Weigh 2.08g of sodium hydroxide solid, slowly pour it into it, and increase the stirring speed to ensure rapid dissolution. After complete dissolution, a wine-red palladium solution was obtained, and the temperature was lowered to 20°C.

[0032] (2) Preparation of cerium oxide colloid: Measure 5ml of cerium nitrate solution with a concentration of 1.16mol / L, dilute it to 32ml with deionized water, stir evenly while adding, and keep the rotating speed at a low speed to ensure uniform stirring. Weigh 2.08g of sodium hydroxide solid, slowly pour it into it to form a precipitate. Cool down and stir for 30 min to form a uniform white colloidal solution and keep the temperature at 20°C.

[0033] (3) Preparation of Pd-loaded cerium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com