Radial particle washing device

A washing device and particle technology, applied in the restoration of polluted soil, etc., can solve the problems of high energy consumption, inability to meet the simultaneous washing of a large number of particles, noise pollution, etc., and achieve the effect of less energy consumption, good washing effect and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

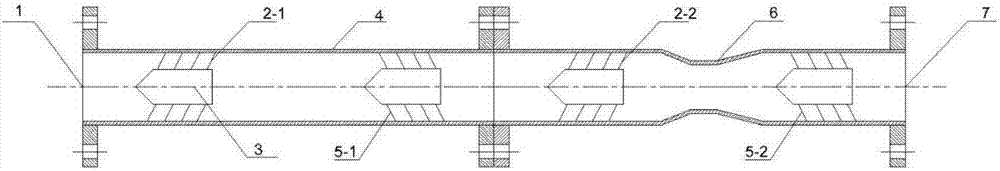

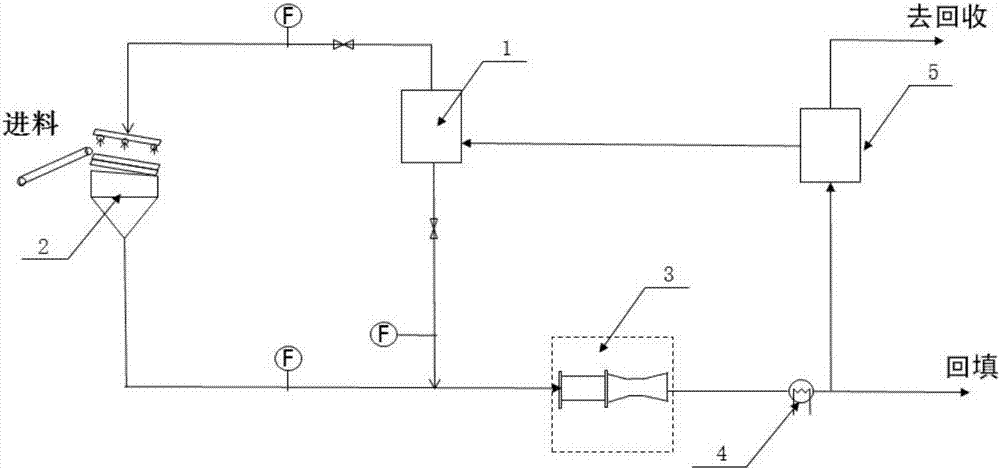

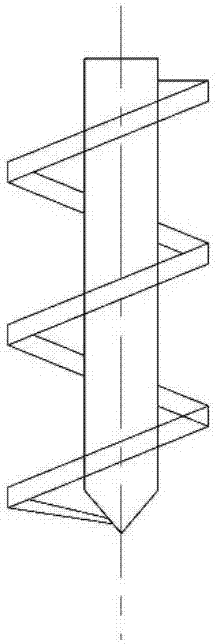

[0030] After extensive and in-depth research, the inventors of the present application found that, for particle washing, the traditional mechanical washing methods mainly include impact jet reactor, stirring vessel and ultrasonic washing method. However, there are many disadvantages in the three methods. For example, the stirring container requires a large space, has relatively large noise, and the temperature difference between the tank center and the material near the tank wall is easy to produce, which affects the washing effect. Another example is the ultrasonic washing device, which has relatively high energy consumption and cannot satisfy a large number of particles to be washed at the same time, and once the sound-absorbing filling material is damaged, the noise pollution will be serious. The method of organic combination of swirl and cavitation can achieve good washing effect, and has compact structure, small space required, low energy consumption and high washing effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com