Leak plate molding mold and molding production method thereof

A technology for molding molds and manufacturing methods, which is applied in molds, ceramic molding machines, manufacturing tools, etc., can solve problems affecting the strength of slatted slats, shorten the service life of slatted slats, corrode and rust reinforced steel bars, etc., and prolong the service life , to ensure the long-term use of strength, to avoid the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, this case is described in further detail.

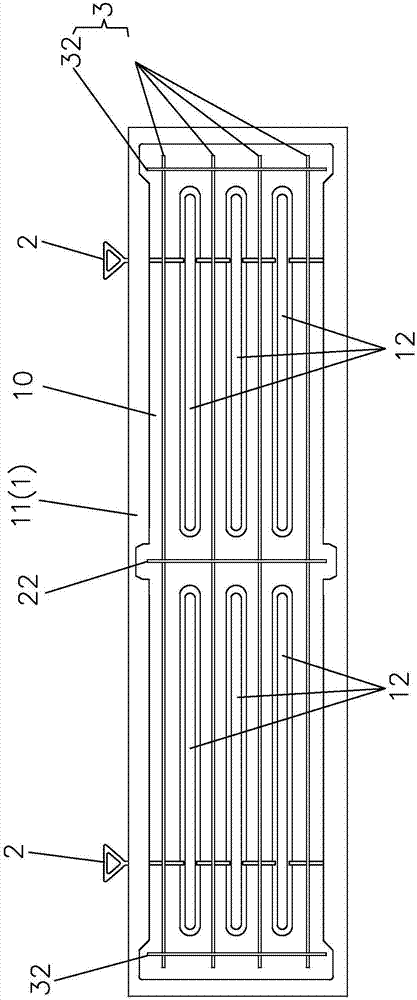

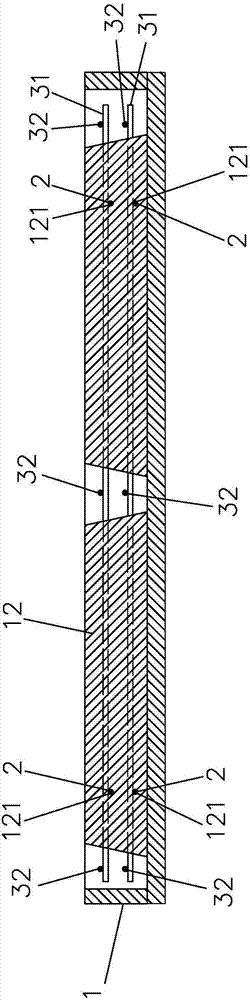

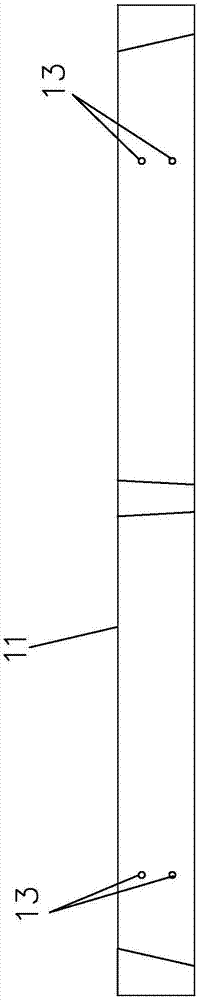

[0033] This case involves a slatted plate forming mold, such as Figure 1-3 As shown, a mold groove 1 and a positioning rod 2 are included.

[0034] The mold groove 1 has a groove cavity 10 bounded by a groove bottom and groove side walls 11 . Several groups of protruding lines 12 are arranged side by side in the groove cavity 10 . The convex strip 12 is a structure corresponding to the slit opening of the formed slatted plate. The shape and size of the groove cavity 10 of the mold groove 1 are designed correspondingly according to the size of the slatted plate to be formed. For example, when forming a strip-shaped slatted plate (size 1.2m*2.5m), there are two groups of slit openings arranged side by side along the length direction, and each group is provided with three side by side along the width direction; the groove cavity 10 corresponding to the mold groove 1 is correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com