Construction basal layer material and construction method

A base layer and civil engineering technology, applied in the direction of roads, roads, buildings, etc., can solve the problems of good anti-seepage performance and high compressive strength, and achieve the effect of simple preparation process, less usage and excellent compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

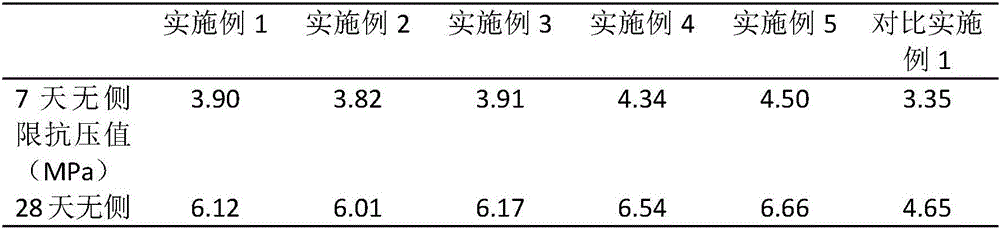

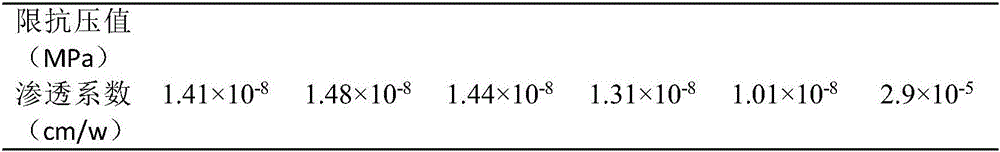

Examples

Embodiment 1

[0019] (1) Prepare the following raw materials by weight percentage: 92% alkali slag, 6% calcium silicate slag and 2% composite additive; the composite additive is composed of the following components by weight percentage: 50% sodium fluorosilicate, 25% sulfuric acid Sodium and triethanolamine 25%;

[0020] (2) After mixing the product obtained in step (1), stir and mix evenly to obtain the product.

Embodiment 2

[0022] (1) Prepare the following raw materials by weight percentage: 94% alkali slag, 5% silicon-calcium slag and 1% composite additive; the composite additive is composed of the following components by weight percentage: 70% sodium fluorosilicate, 25% sulfuric acid Sodium and triethanolamine 5%;

[0023] (2) After mixing the product obtained in step (1), stir and mix evenly to obtain the product.

Embodiment 3

[0025] (1) Prepare the following raw materials by weight percentage: 93% alkali slag, 5% silicon-calcium slag and 2% composite additive; the composite additive is composed of the following components by weight percentage: 60% sodium fluorosilicate, 25% sulfuric acid Sodium and triethanolamine 15%;

[0026] (2) After mixing the product obtained in step (1), stir and mix evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com