Decoupling drive-by-wire brake system and control method thereof

A brake-by-wire and decoupling technology, applied in the direction of brakes, brake transmission devices, automatic starting devices, etc., can solve the problems of high design standards and defective configuration scheme safety, and achieve lower response requirements and lower power requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0061] One, overall structure of the present invention:

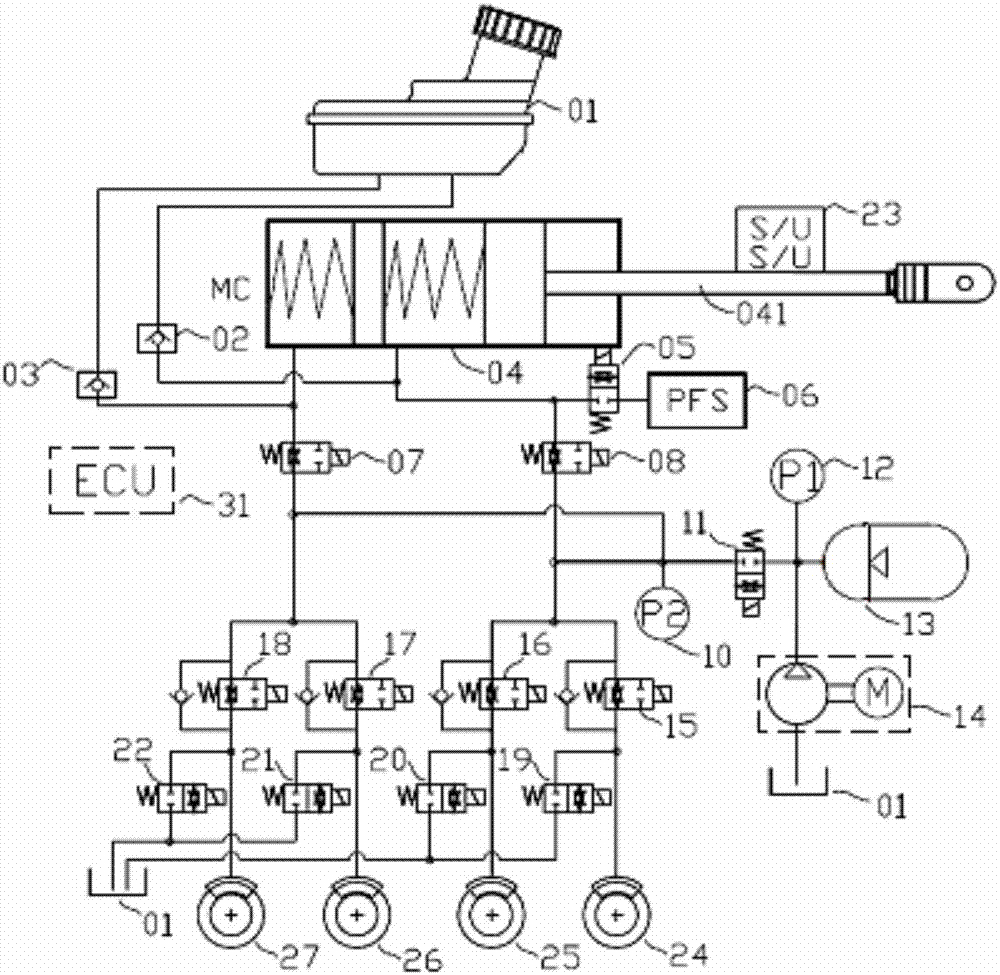

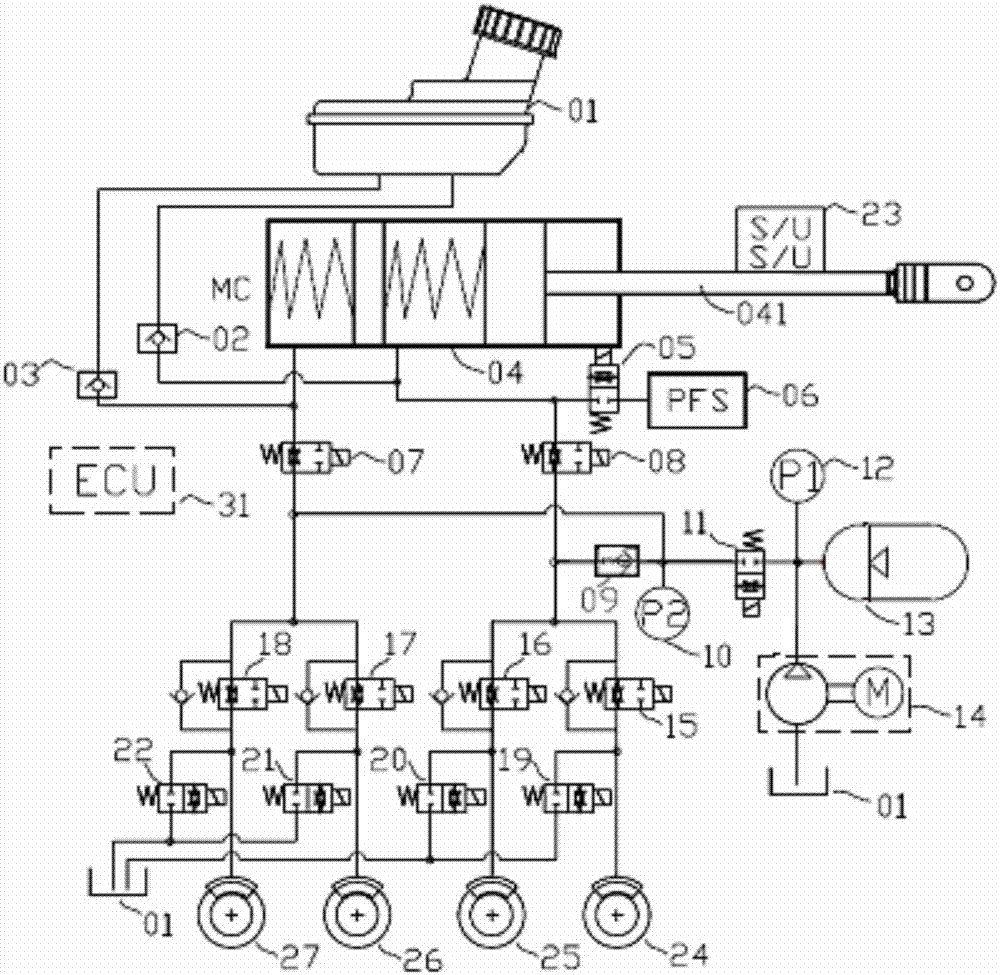

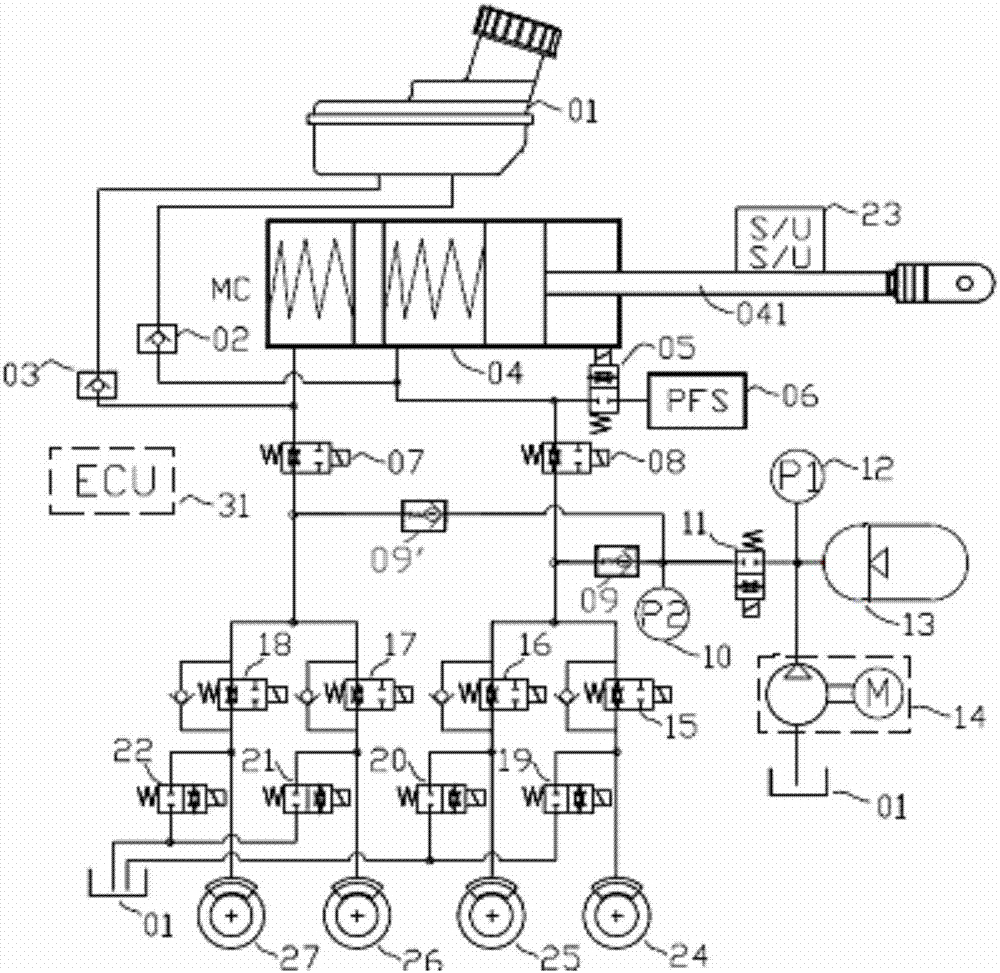

[0062] 1, figure 1 It is a structural schematic diagram of the wire-controlled hydraulic brake system of the present invention.

[0063] Two one-way valves 02 and 03 are connected between the brake master cylinder 04 and the oil pot 01, and the conduction direction of the one-way valves is from the oil pot to the brake master cylinder; the master cylinder stroke sensor 23 It is not limited to use single-channel and multi-channel linear sensors, linear displacement sensors, or angular displacement sensors.

[0064] The pedal feeling simulator PFS06 is connected to one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com