Modified silica gel carrier and supported metallocene catalyst, preparation methods thereof as well as metallocene catalyst system

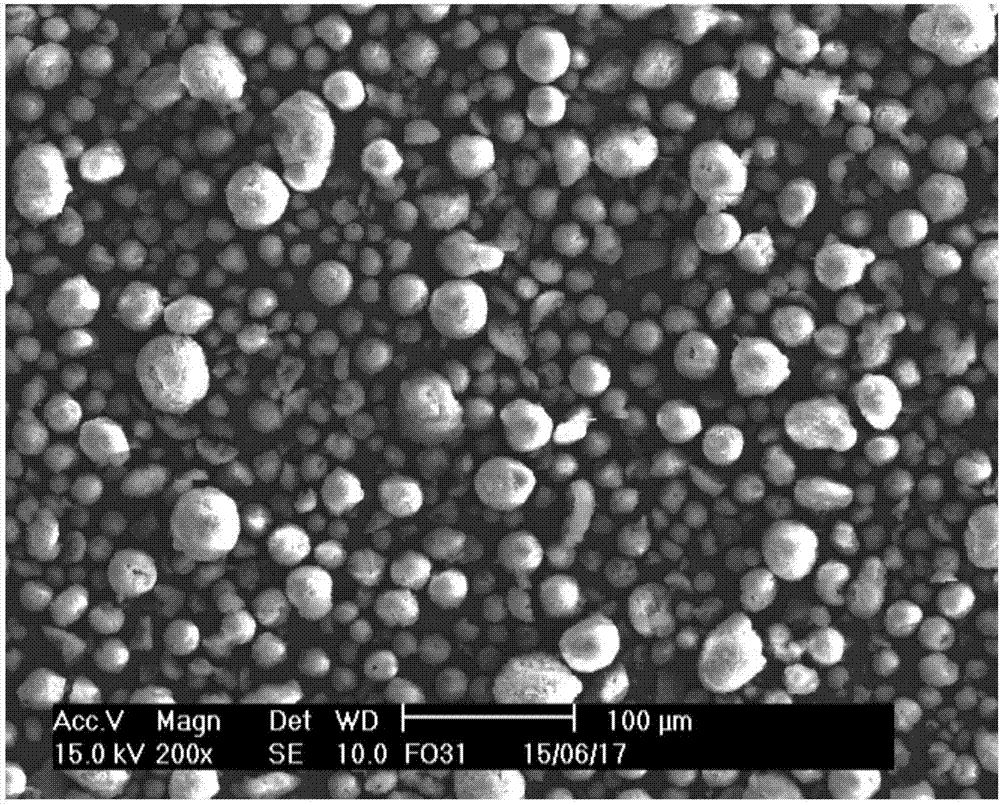

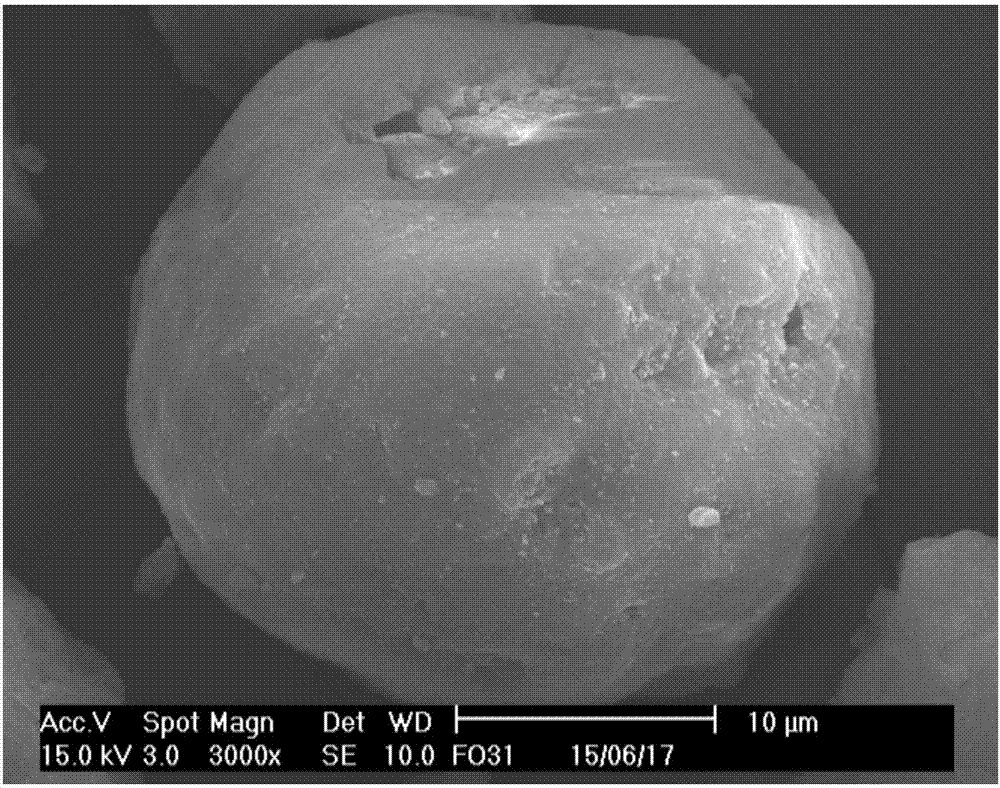

A metallocene catalyst and metallocene technology, applied in the field of supported metallocene catalyst and its preparation, modified silica gel carrier and its preparation, metallocene catalyst system for olefin polymerization, can solve uncontrollable, poor particle shape of carrier, polymerization The molecular weight of the compound and its distribution changes, etc., to achieve the effect of simple preparation method, high bulk density and high polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

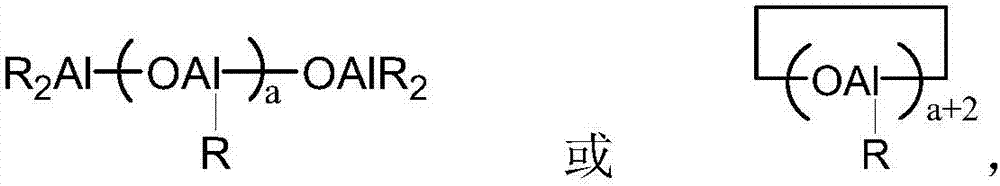

[0030] According to a second aspect of the present invention, the present invention provides a method for preparing the above-mentioned modified silica gel carrier, the method comprising:

[0031] 1) In the presence of the first solvent, manganese chloride is reacted with silica gel to obtain a manganese chloride / silica gel carrier;

[0032] 2) Reacting the manganese chloride / silica gel support with an alkylaluminoxane in the presence of a second solvent.

[0033] In step 1), based on the total weight of manganese chloride and silica gel, the amount of manganese chloride can be 0.1-60% by weight, preferably 0.5-45% by weight.

[0034] In step 1), the reaction is usually carried out under the protection condition of an inert gas (for example, nitrogen). The first solvent can be used to dissolve the manganese chloride, and then the silica gel can be added to carry out the reaction. The reaction can be carried out under stirring, and the reaction conditions can include: the tem...

Embodiment 1

[0079] This example is used to illustrate the modified silica gel carrier and supported metallocene catalyst of the present invention and their respective preparation methods.

[0080] 1) Preparation of manganese chloride / silica gel carrier

[0081] Under the protection of nitrogen, add 0.52 g of anhydrous manganese chloride to the glass reactor at room temperature, then add 350 ml of tetrahydrofuran, start stirring, add 13.9 g of silica gel into the reactor, raise the temperature to 65 ° C, stir and dissolve for 2 hours , and the solvent was evaporated at 80°C to obtain a white solid powder. The white solid powder was vacuum-dried at 100°C for 2 hours, and then vacuum-dried at 300°C for 10 hours to obtain a manganese chloride / silica gel carrier with good fluidity. Through gas chromatography analysis, no tetrahydrofuran was detected.

[0082] 2) Preparation of alkylaluminoxane / manganese chloride / silica gel carrier

[0083] Under nitrogen protection, take 4.64 grams of the ma...

Embodiment 2

[0087] This example is used to illustrate the modified silica gel carrier and supported metallocene catalyst of the present invention and their respective preparation methods.

[0088] 1) Preparation of manganese chloride / silica gel carrier

[0089] Under the protection of nitrogen, add 0.8 g of anhydrous manganese chloride to the glass reactor at room temperature, then add 250 ml of tetrahydrofuran, start stirring, add 7.0 g of silica gel into the reactor, heat up to 65 ° C, stir and dissolve for 2 hours, The solvent was evaporated at 80°C to give a white solid powder. The white solid powder was vacuum-dried at 100°C for 2 hours, and then vacuum-dried at 300°C for 10 hours to obtain a manganese chloride / silica gel carrier with good fluidity. Through gas chromatography analysis, no tetrahydrofuran was detected.

[0090] 2) Preparation of alkylaluminoxane / manganese chloride / silica gel carrier

[0091] Under the protection of nitrogen, take 4.13 grams of the manganese chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com