Pure cotton punched non-woven fabric and preparation method and application thereof

A non-woven fabric, pure cotton technology, applied in the fields of medical science, bandages, metal processing, etc., can solve the problem of re-wetting of pure cotton non-woven fabrics, achieve soft hand feel, small amount of re-moisture, and improve comfort and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

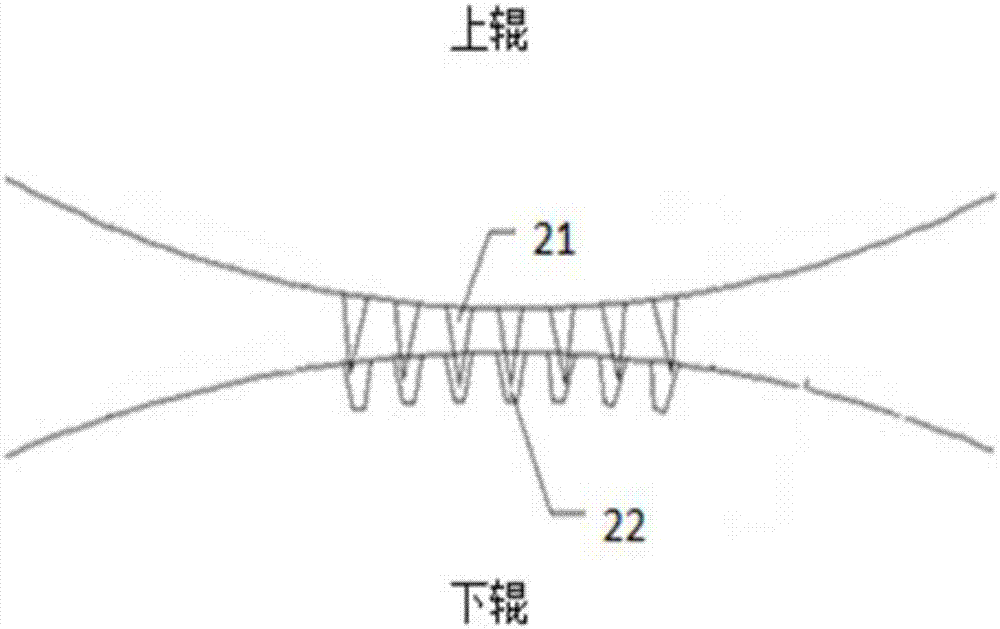

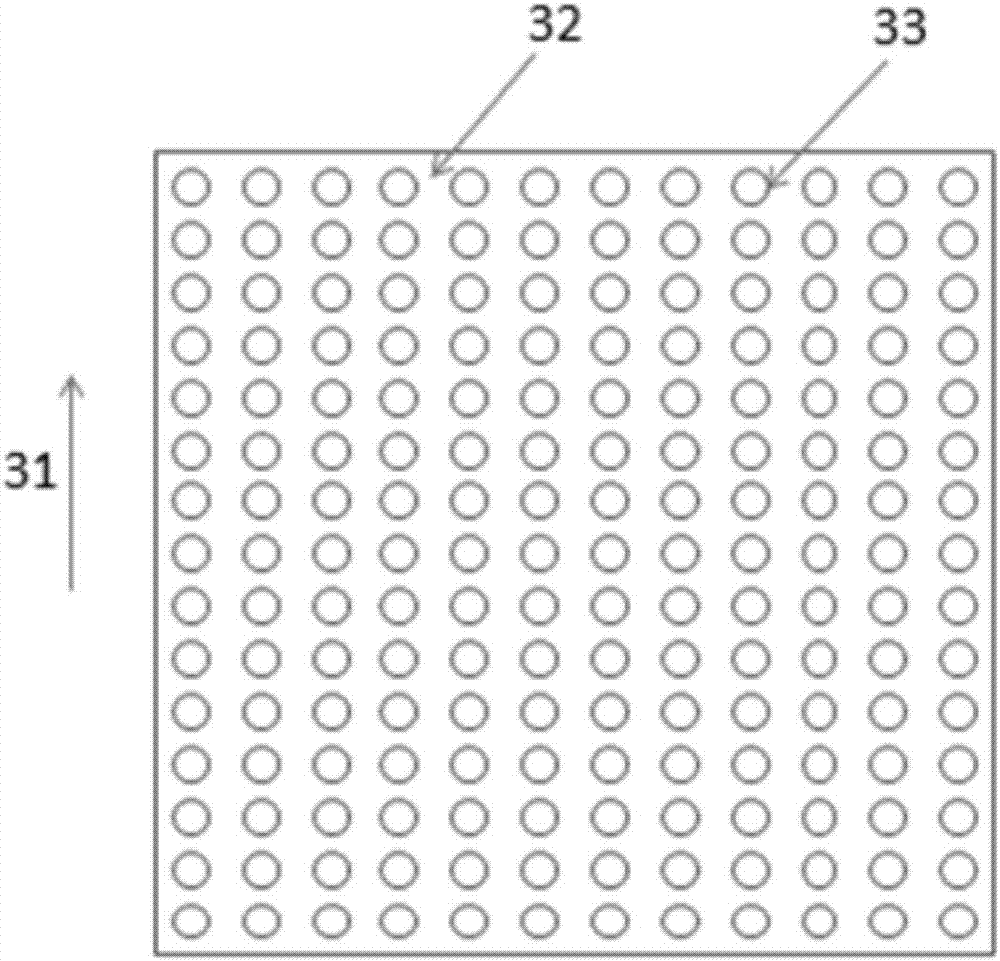

[0027] Example 1: The nonwoven fabric includes a fiber web, and 100% natural cotton fibers are pre-opened, mixed, finely opened, carded into a web, and finely entangled with high-pressure water needles. The non-woven fabric is composed of 100% cotton fibers. Due to the natural characteristics of cotton, the fineness and length are irregular and fluctuating compared with ordinary chemical fibers. The difficulty of carding and high-pressure water needle entanglement in the production process is more difficult than that of ordinary chemical fibers. High in fiber. The thickness of the pure cotton nonwoven fabric ranges from 0.3 to 1.5mm, and the weight is 25-50g / m 2 .

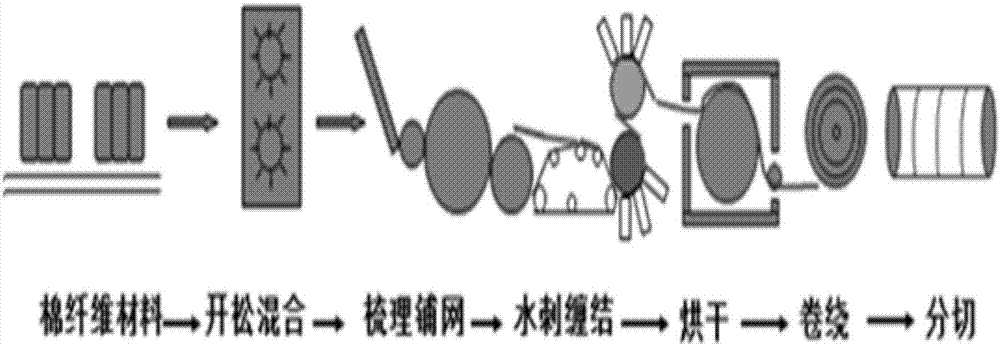

[0028] The preparation steps of pure cotton perforated spunlaced nonwoven fabric: put the whole package of cotton fibers in the raw material buffer room in advance, which is close to the production environment, which is beneficial to the subsequent processing. The continuous production process of pure cotton spun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com