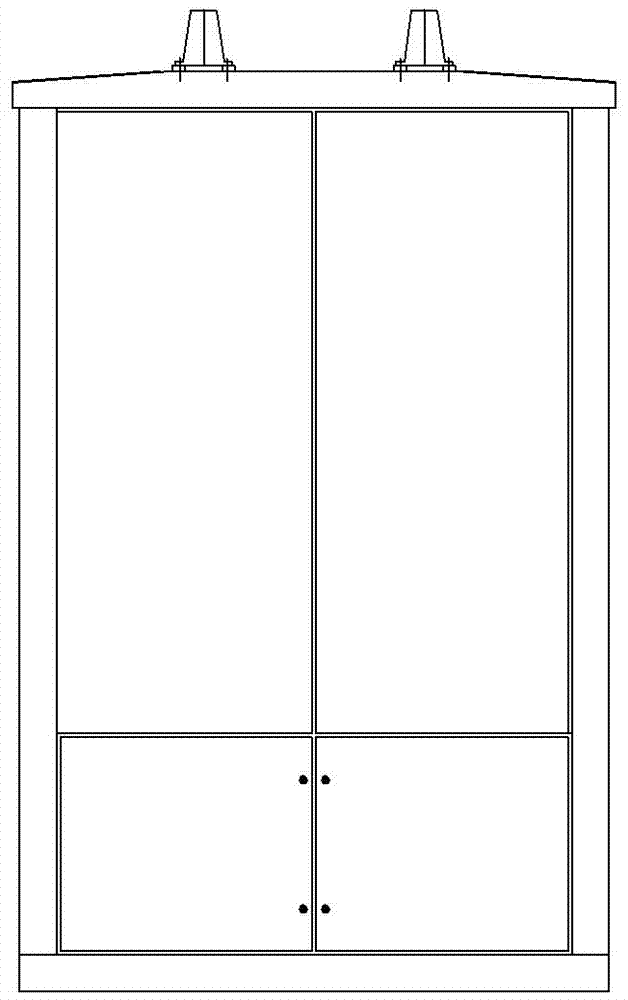

Floor type isolated switch cabinet for overhead line system

A technology of isolating switch and catenary, applied in substation/switch layout details, electrical components, substation/distribution device casing, etc., can solve the problem of affecting the accuracy of switch opening and closing contacts, etc., to achieve stable video quality and prevent banding The effect of load operation and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

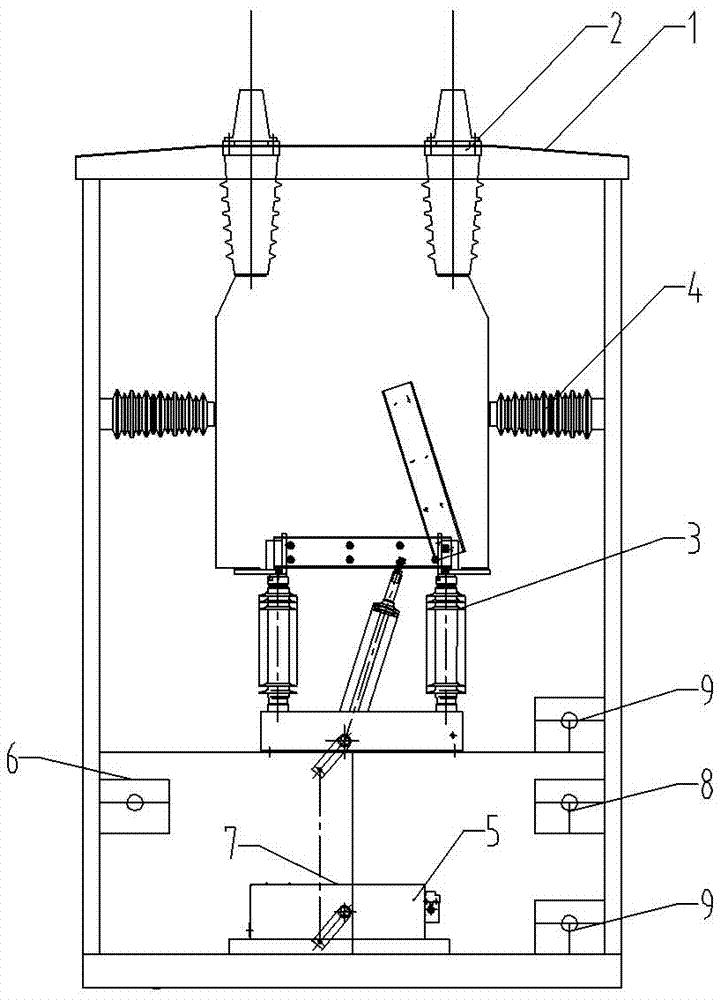

[0033] The present invention will be described in detail below in combination with specific embodiments.

[0034] Catenary isolating switch of electrified railway undertakes important functions such as switching of power supply mode of traction network, electric energy distribution and electrical isolation of catenary, and is widely used in feeder network, separation phase and station. At present, the catenary isolating switches of electrified railways are all installed outdoors on the top of the column or on the side of the column. The rotating transmission rod of the output shaft of the isolating switch operating mechanism is about 8 meters long. When the isolating switch is driven to close and open, the angular displacement of the output shaft of the mechanism cannot be completely transmitted to the isolating switch body due to the natural sag of the transmission rod, which will cause the switch to close. , The opening is not in place. Especially in windy conditions.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com