On-line heat preservation and slow cooling device for steel belt manufacturing assembly line

A heat preservation and slow cooling, assembly line technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of cold rolling process adverse effects, steel strip deformation, temperature drop, etc., to prevent heat loss and deformation , the effect of slowing down the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

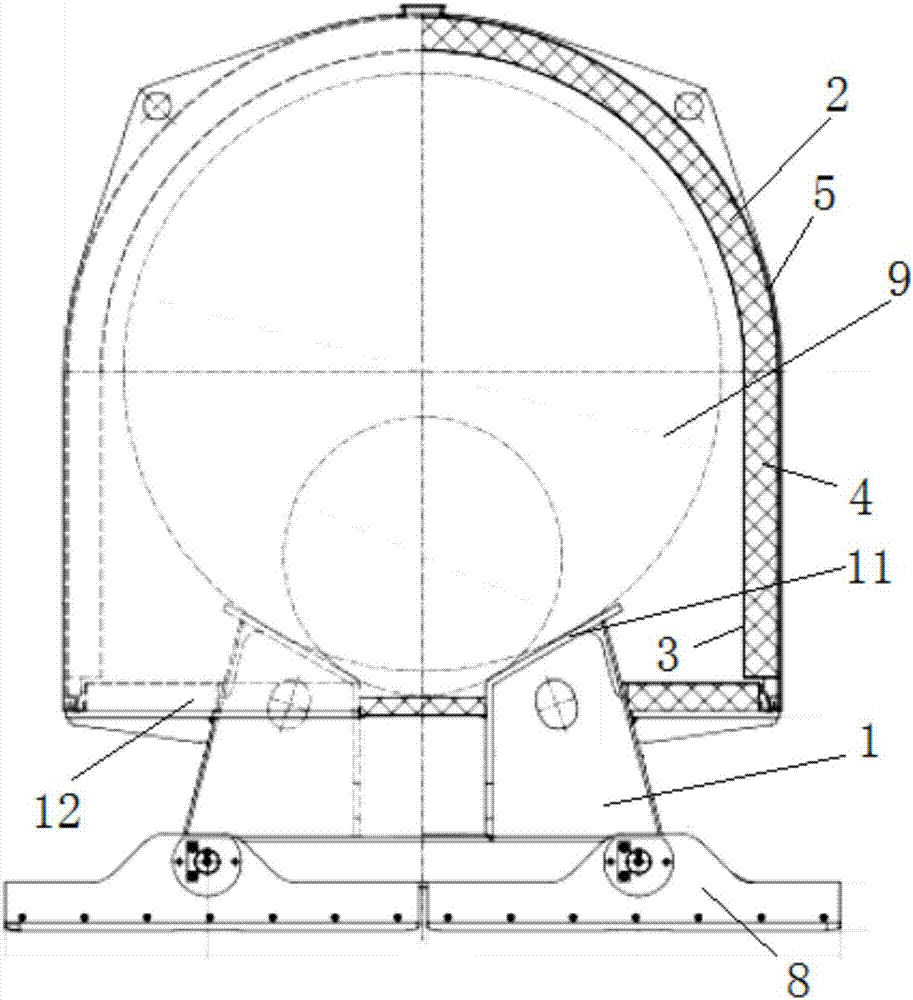

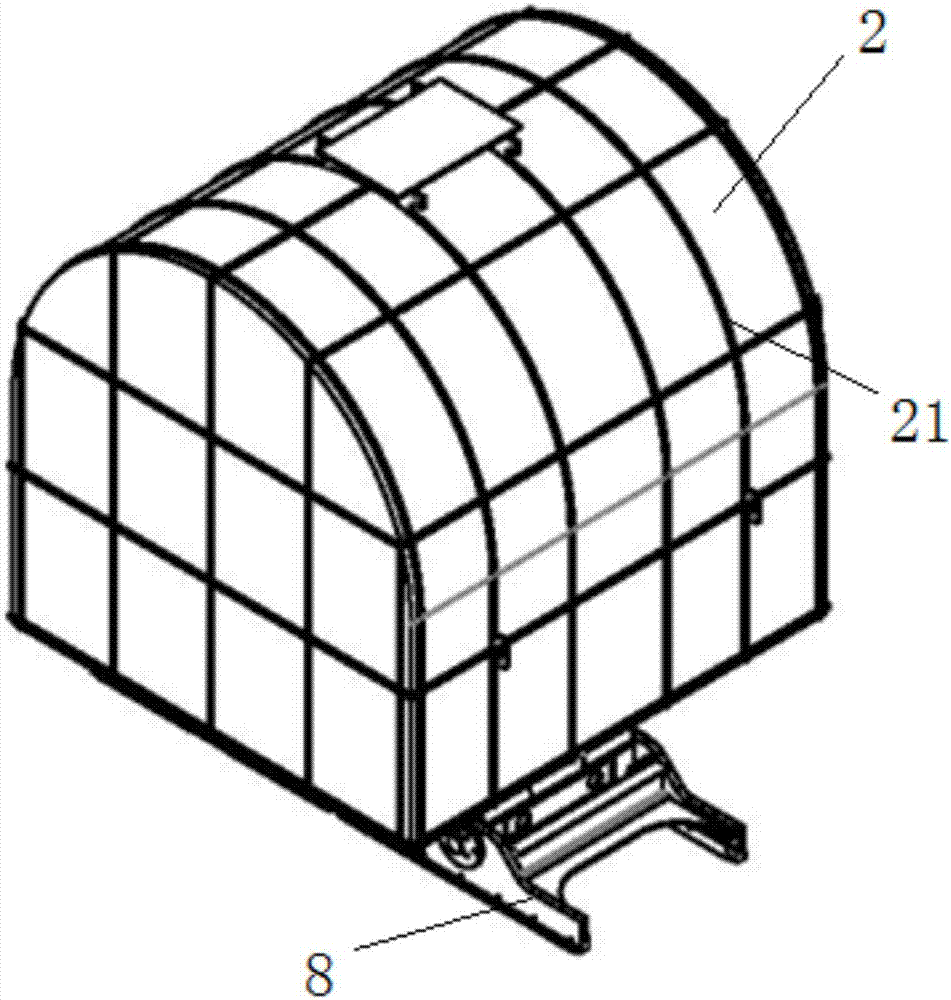

[0024] Such as figure 1 and figure 2 As shown, the online heat preservation and slow cooling device of the steel strip manufacturing line includes a steel strip coil tray 1 and a heat preservation cover 2 .

[0025] Wherein, the upper end of the steel coil tray 1 is provided with a V-shaped groove 11, the V-shaped groove 11 is used to place the steel coil 9, the lower end of the steel coil tray 1 is connected with the assembly line 8, and the middle part of the steel coil tray 1 is provided with a rectangular chassis 12, The chassis 12 is arranged in parallel with the assembly line 8;

[0026] The heat preservation cover 2 is arranged on the chassis 12 to form a heat preservation cavity. The shape of the inner cavity of the upper part of the heat preservation cover 2 matches the steel strip coil 9 and is arc-shaped.

[0027] Both the chassis 12 and the insulation cover 2 are multilayer composite insulation structures, and the multilayer composite insulation structure includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com