Manufacturing method for easily-rebounded S-shaped-section sheet metal part and multi-station progressive die

A multi-station progressive die and production method technology, applied in the field of metal stamping, can solve the problems of large mold debugging workload, affecting product production efficiency, increasing mold debugging cost input, etc., to improve production efficiency and product qualification rate. , the effect of shortening the development cycle and reducing the debugging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

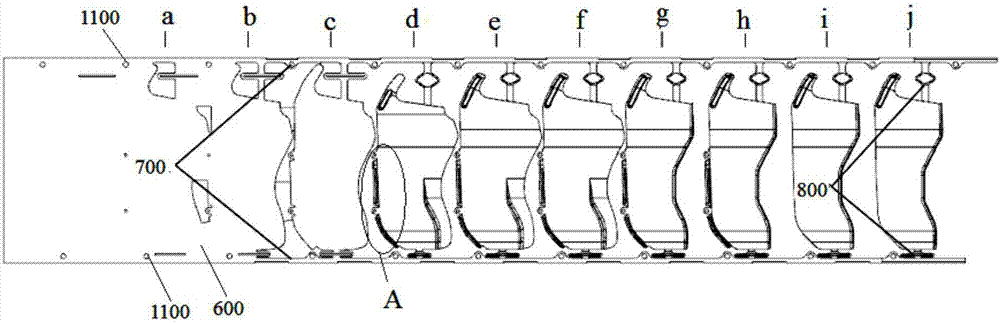

[0051] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

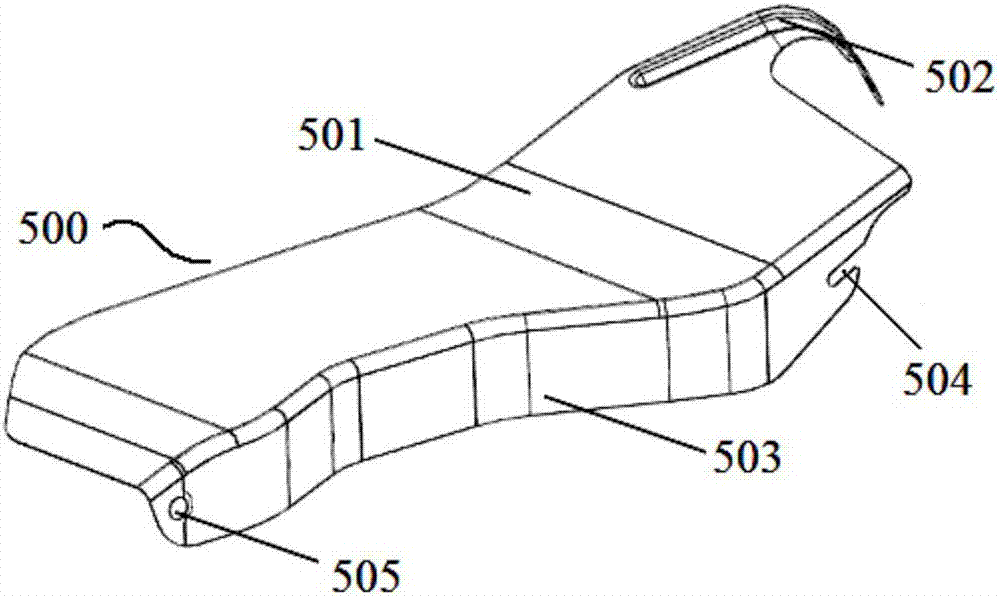

[0052] The present invention provides a method for manufacturing an easily resilient S-shaped cross-section sheet metal part. The structure of the easy-rebound S-shaped cross-section sheet metal part 500 is as follows: figure 1As shown, the easily resilient S-shaped section sheet metal part 500 includes a sheet metal part body 501, a first bending part 502 connected to one end of the sheet metal part body 501 and a side edge connected to the sheet metal part body 501 The second bending portion 503, the first bending portion 502 and the second bending portion 503 are formed by bending and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com