Novel hydraulic tailstock mandrel structure

A hydraulic tailstock and mandrel technology, applied in tailstock/top, turning equipment, tool holder accessories, etc., can solve the problems of cumbersome installation, large space requirements, and complicated mechanism, so as to reduce processing costs and ensure complete travel control, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

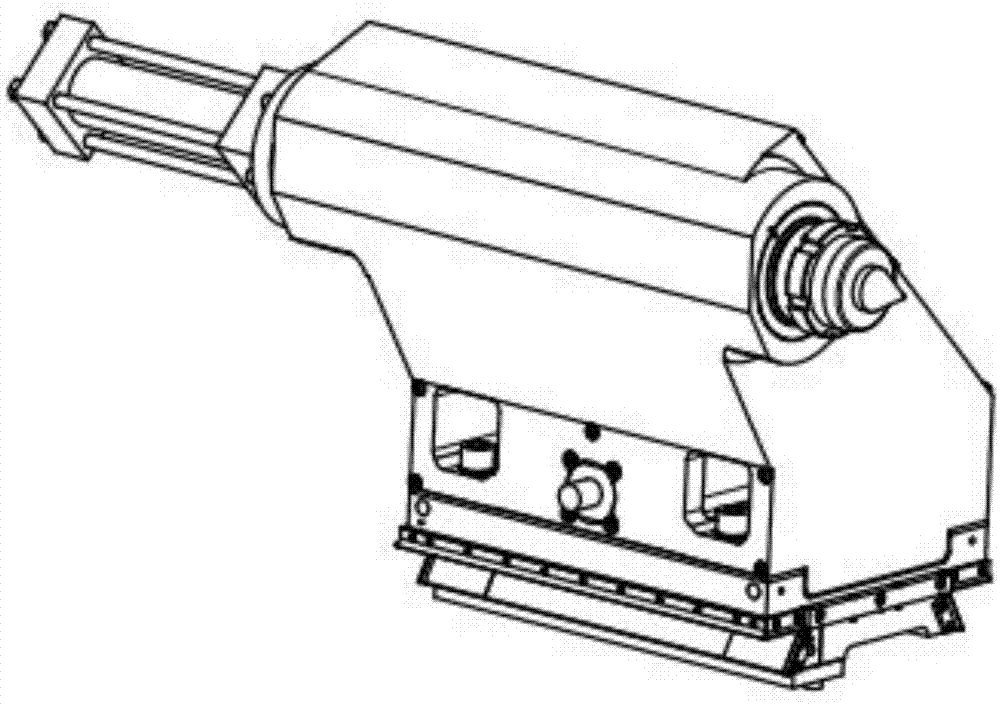

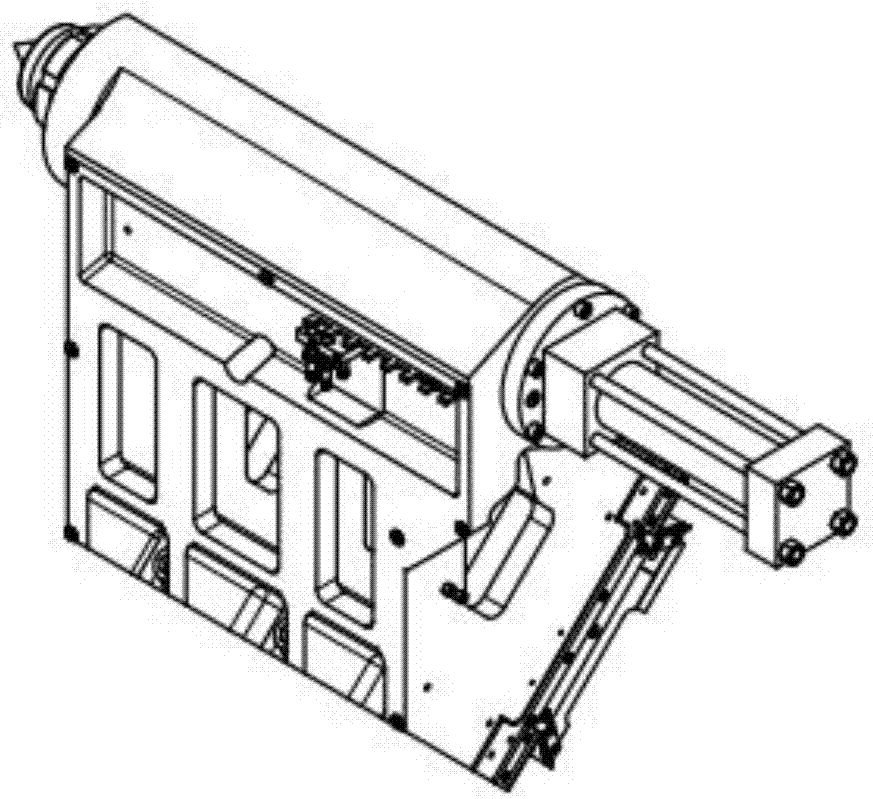

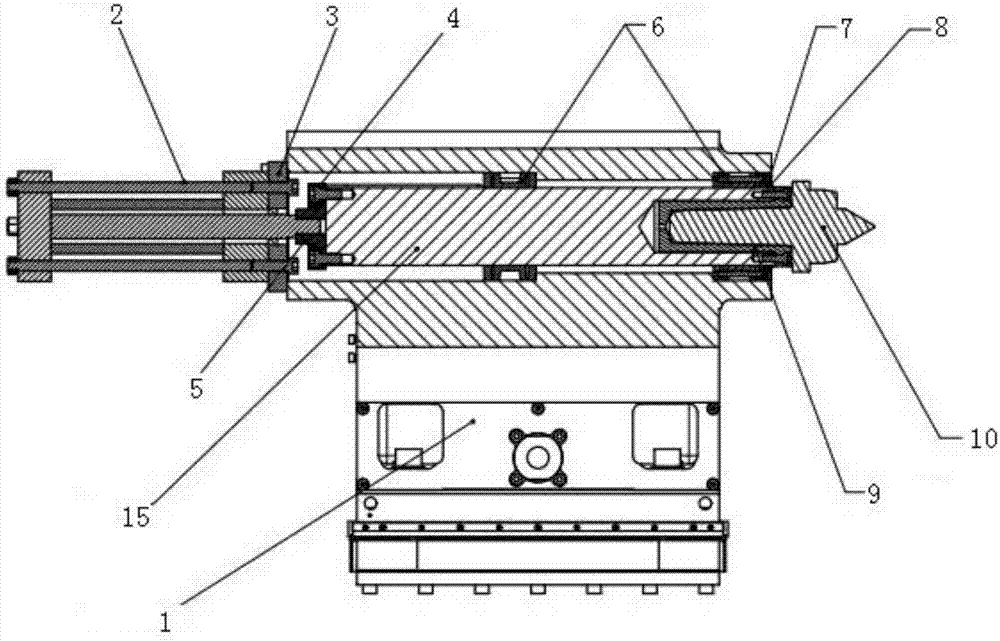

[0018] Such as Figure 1-4 As shown, a new hydraulic tailstock mandrel structure, including tailstock body 1, tailstock cylinder 2, cylinder flange 3, mandrel flange 4, piston connecting nut 5, guide sleeve 6, retaining ring 7, scraper 8. Top sleeve 9, top 10, T-shaped block 11, reading ruler 12, proximity switch bracket 13, proximity switch 14, mandrel 15 and bolt 16.

[0019] A guide sleeve 6 is fixedly installed on the tailstock body 1 , and a mandrel 15 is housed in the guide sleeve 6 .

[0020] A top sleeve 9 is fixedly installed on the head of the mandrel 15, and a top 10 is arranged in the top sleeve 9, and a retaining ring 7 and a scraper 8 are installed to complete the telescopic structure of the tailstock.

[0021] A tailstock oil cylinder 2 is fixedly installed at the tail of the mandrel 15, and the oil cylinder flange 3 and the mandrel flange 4 are sleeved on the tailstock oil cylinder 2 in sequence, and the piston connecting nut 5 is screwed on the oil cylinder p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com