Processing device for clutch hole of engine cover

An engine cover and processing device technology, applied in positioning devices, clamping devices, metal processing equipment, etc., can solve the problems of high procurement cost, difficult for ordinary workers, and difficult to maintain, and achieves convenient use, low failure rate, and chip removal. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

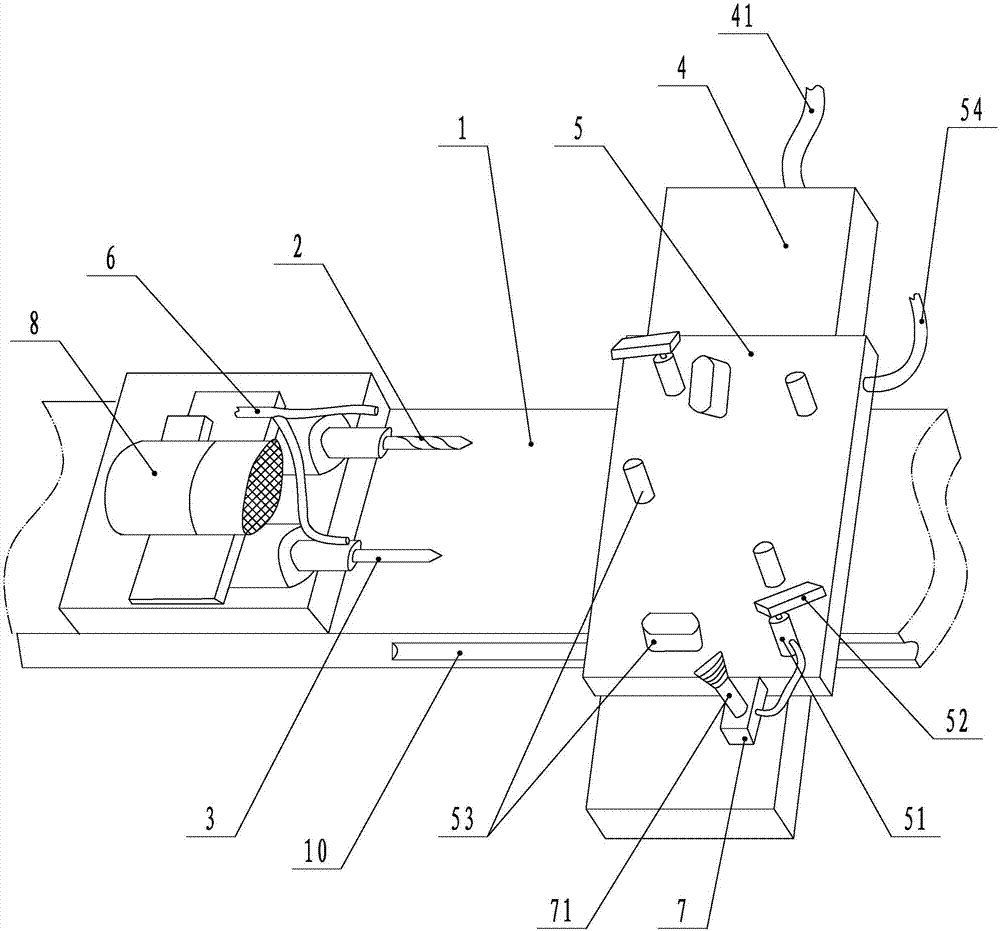

[0016] refer to figure 1 , an engine cover clutch hole processing device, comprising a drilling mechanism and a workbench 1, the workbench 1 is inclined upward, and the inclination angle is set according to actual needs, the drilling mechanism is fixedly installed on the workbench 1, and the workbench The other side of the table 1 opposite to the drilling mechanism is provided with a longitudinal mounting plate 4, and the longitudinal mounting plate 4 is connected with a transverse driving mechanism 41. The transverse driving mechanism 41 is preferably a pneumatic driving mechanism, and its driving response is fast and the cost is relatively low. The lateral sides of the workbench 1 are provided with chute 10, the longitudinal mounting plate 4 is provided with a clamping part adapted to the chute 10, and the longitudinal mounting plate 4 is clamped on the chute 10 through the clamping part to be connected with the working The table 1 is slidingly connected, and the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com