MIG (Metal-Inert Gas) and TIG (Tungsten Inert Gas) combined welding process for longitudinal seam welding of aluminum material

A longitudinal seam welding and welding process technology, applied in the field of aluminum welding, can solve the problems of insufficient aesthetics of the welding area, long production time, and many processes, and achieve the effects of improving aesthetics, reducing production time, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

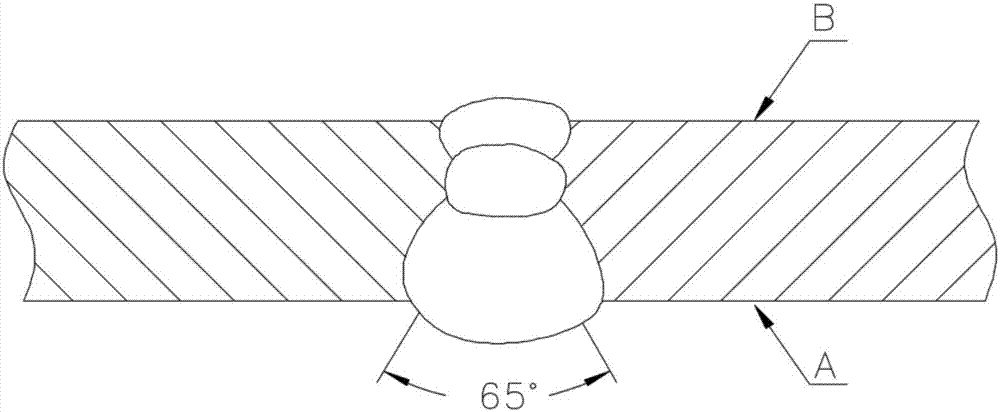

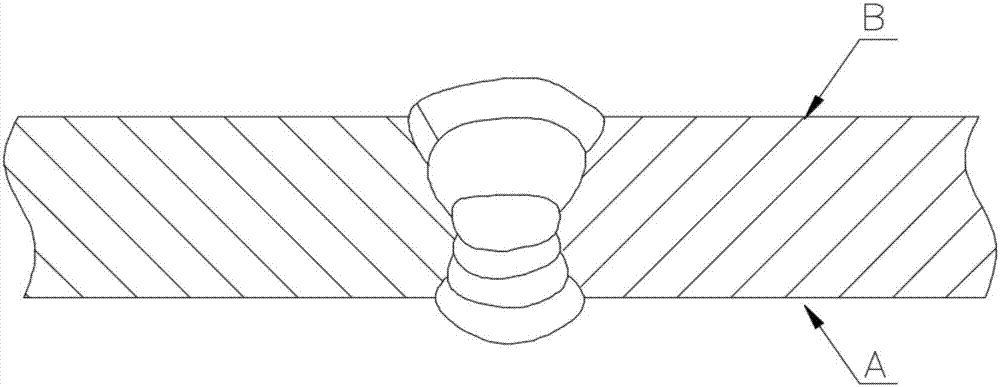

[0025] see figure 1 , the present invention provides a technical solution: a combined MIG and TIG welding process for longitudinal seam welding of aluminum materials, comprising a cylinder, the A surface of which is the outer surface, and B is the inner surface, comprising the following steps:

[0026] Step 1: Remove the poorly formed welds in the shell, use a stainless steel wire wheel to remove the oxide film at the welds of the cylinder, and mill out a "V"-shaped outer groove on the A surface of the cylinder;

[0027] Step 2: Adopt double-pulse MIG welding to form an automatic welding MIG bottoming area in the middle of the cylinder, and use automatic argon arc welding on the outside. The welding wire is DW-309L flux-cored wire, and the protective gas is filled during welding to protect The gas is 100% carbon dioxide, and a MIG and TIG synchronous welding zone is formed on the A side of the cylinder. The specific parameters are as follows:

[0028]

[0029] Step 3: Aut...

Embodiment 2

[0035] see figure 1 , the present invention provides a technical solution: a combined MIG and TIG welding process for longitudinal seam welding of aluminum materials, comprising a cylinder, the A surface of which is the outer surface, and B is the inner surface, comprising the following steps:

[0036] Step 1: Remove the poorly formed welds in the shell, use a stainless steel wire wheel to remove the oxide film at the welds of the cylinder, and mill out a "V"-shaped outer groove on the A surface of the cylinder;

[0037] Step 2: Use MIG welding double-pulse bottoming to form an automatic welding MIG bottoming area in the middle of the cylinder, and use automatic argon arc welding on the outside. The welding wire is ER5356ф1.6mm, and the protective gas is filled during welding. The protective gas is 100 % carbon dioxide, the MIG and TIG synchronous welding zones are formed on the A side of the cylinder, and the specific parameters are as follows:

[0038]

[0039] Step 3: ...

Embodiment 3

[0045] see figure 1 , the present invention provides a technical solution: a combined MIG and TIG welding process for longitudinal seam welding of aluminum materials, comprising a cylinder, the A surface of which is the outer surface, and B is the inner surface, comprising the following steps:

[0046] Step 1: Remove the poorly formed welds in the shell, use a stainless steel wire wheel to remove the oxide film at the welds of the cylinder, and mill out a "V"-shaped outer groove on the A surface of the cylinder;

[0047] Step 2: Adopt double-pulse MIG welding to form an automatic welding MIG bottoming area in the middle of the cylinder, and use automatic argon arc welding on the outside. The welding wire is DW-309L flux-cored wire, and the protective gas is filled during welding to protect The gas is 100% carbon dioxide, and a MIG and TIG synchronous welding zone is formed on the A side of the cylinder. The specific parameters are as follows:

[0048]

[0049] Step 3: Aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com