Intelligent soft robot for detecting interior wall defects in narrow space

A small space, robot technology, applied in manipulators, micro manipulators, manufacturing tools, etc., can solve the problems of many system parts, poor environmental adaptability, and high technology dependence, and achieve easy biocompatibility, high monitoring accuracy, and environmental protection. good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below by means of the accompanying drawings and examples.

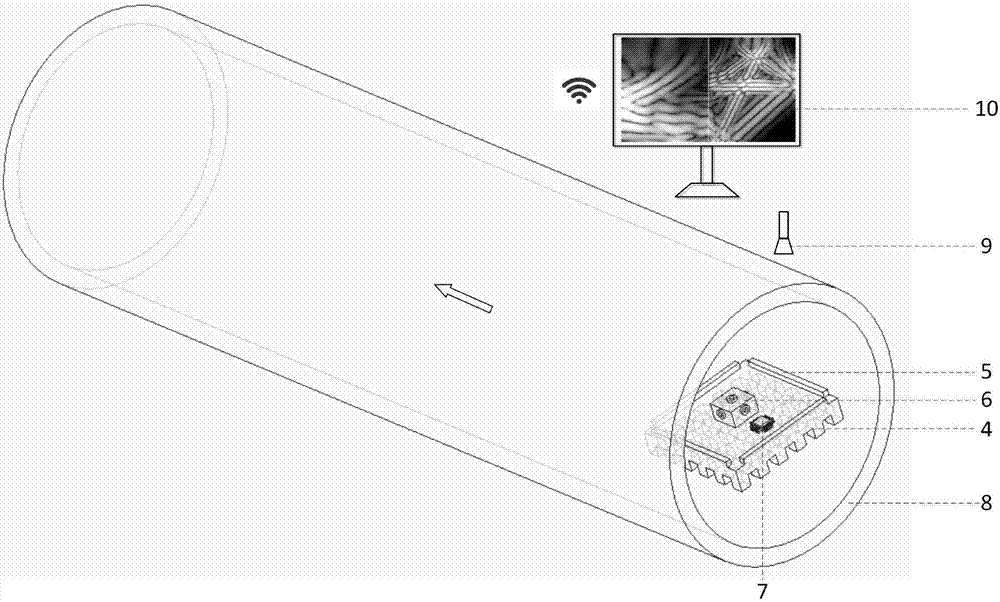

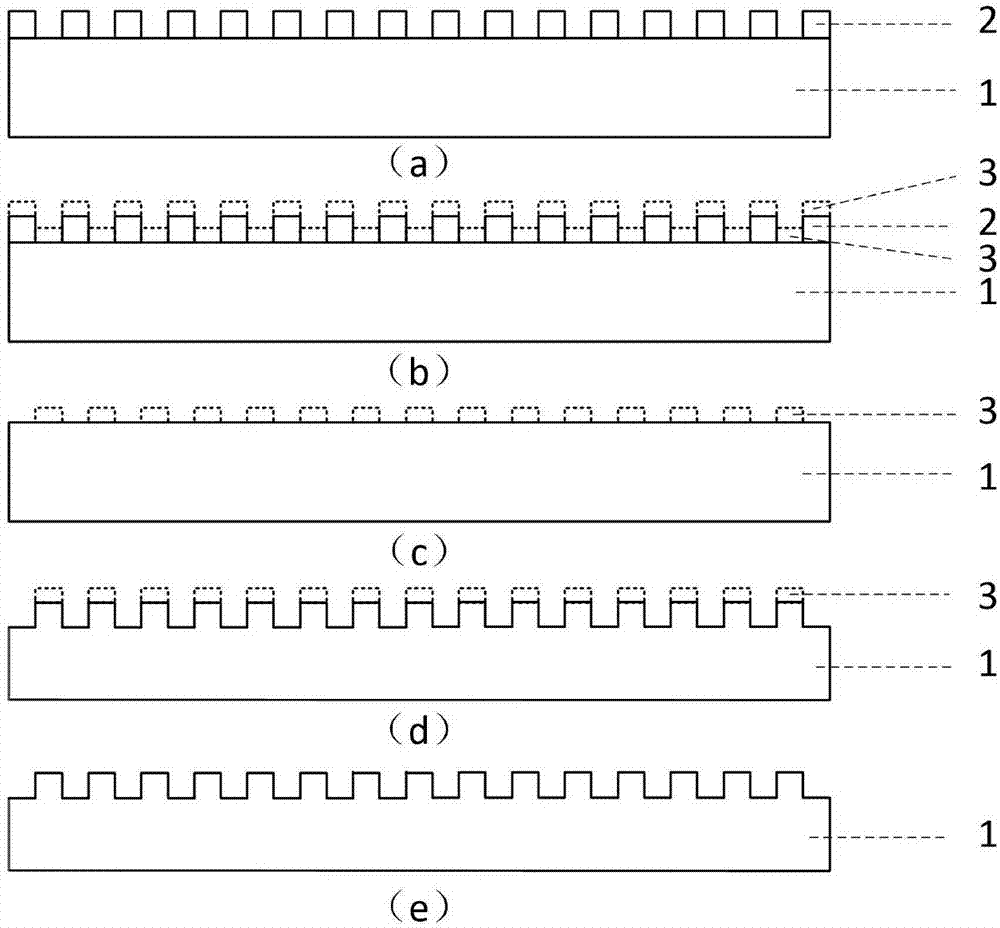

[0025] refer to figure 1 , an intelligent soft robot for monitoring inner wall defects in a narrow space, comprising A intelligent material layer 4, B intelligent material layer 5 is arranged around the upper surface of A intelligent material layer 4, and the center of the upper surface of A intelligent material layer 4 is equipped with monitoring and signal Processing system 6, the microstructure side of A smart material layer 4 contacts the liquid in the narrow space 8, B smart material layer 5 senses the stimulus emitted by the external driving source 9, and implements remote driving, and the monitoring and signal processing system 6 pairs the inner wall of the narrow space 8 Defects are monitored online; the defect images monitored by the monitoring and signal processing system 6 are transmitted to the signal receiving and display system 10 outside the narrow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com