Photocurable fluoropolyether-based rubber composition, cured product thereof, method for suppressing foaming of cured fluoropolyether-based rubber during sealing and curing

A rubber composition and photocurable technology, applied in the direction of coating, etc., can solve the problems of unstable physical properties, rubber foaming, poor appearance, etc., and achieve the effect of stabilizing physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0240] The following shows examples and comparative examples of the present invention specifically, but the present invention is not restricted by the following embodiment Examples. Incidentally, in the following examples, Me represents a methyl group, parts represents parts by mass. Further, the viscosity denotes measured values (according to JIS K7117-1) at 23 ℃. GPC analysis indicates a molecular weight of a fluorine-based solvent is used as the eluent in the polystyrene equivalent number average molecular weight. Further, the fluorine content (%) indicates mass%.

[0241] Manufacturing photocurable fluoropolyether rubber composition by mixing with base

manufacture example

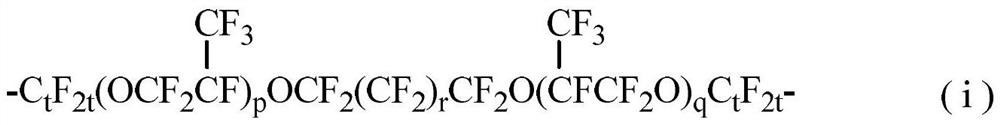

[0243] In the polymer (viscosity of 9,000mPa · s, an amount of vinyl 0.013 mol / 100g, number average molecular weight 15,700) 100 parts of a hydrophobic silica in the filler is fumed silica is represented by the following formula (6) silicon (trade name AEROSILR972: BET specific surface area of 130m 2 / G: of AEROSIL Japan (Co., Ltd.) trade name) was added portionwise 10 parts of a planetary mixer, a kneading for 1 hour. Next, a heat treatment at 150 deg.] C under a reduced pressure mixed (-0.08 ~ -0.10MPa) 1 hour, dispersed with a three-roll After cooling, the manufacture of the base compound.

[0244] [36] of

[0245]

[0246] (M + n ≒ 90)

[0247] [A linear polyfluoro compound and a fluorinated organohydrogenpolysiloxane compatible confirmation]

reference example 1

[0249] Expressed with respect to 100 parts of the polymer, a fluorine-containing organohydrogenpolysiloxane represented by the following formula (7) 3.12 parts (Si-H group content of 0.00500 mol / g, fluorine content by the above formula (6): 41.1%), at room temperature with (23 ℃) mixing means (of THINKY Corporation ARE-310) was stirred at 2,000rpm for 1 minute, then, centrifuged for 1 minute at 2,200rpm for degassing, and then, static at 23 ℃ stand for 1 hour, the transparency was visually confirmed that the mixed solution. The results are shown in Table 1.

[0250] [37] of

[0251]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com