Pearl skin-care tweed and production technology thereof

A production process and tweed technology, applied in the field of textile fabrics, can solve the problem of rarely wearing close-fitting clothing, and achieve the effect of maintaining fair skin, promoting activity, and wearing comfortably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

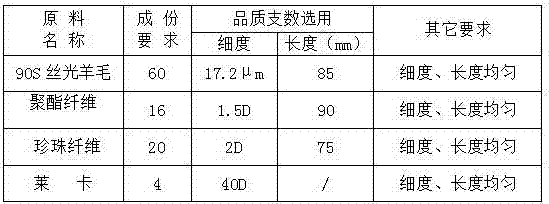

[0025] The present invention selects the parameter of raw material as follows:

[0026]

[0027] A kind of production technology of pearl skin care tweed as mentioned above comprises the steps:

[0028] (1) Dyeing process

[0029] Mercerized wool fiber: Because mercerized wool is chlorinated and mercerized, the scale layer of wool is destroyed, the barrier to dye is eliminated, the dyeing performance is greatly improved, and the fuel is easily diffused into the fiber. Imported Huntsman environmentally friendly wool is dyed with low-temperature reactive dyes, the dyeing temperature is controlled at 80°C, and the temperature is kept for 60 minutes. In order to protect the fibers from damage and reduce yarn breakage and short wool in the process of spinning and weaving, which is convenient for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com