Method for injecting high-temperature nitrogen gas for improving coal body permeability after liquid nitrogen gasification circulation

A gas-permeable, liquid nitrogen technology, applied in the fields of mining fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of high-efficiency production safety hazards in coal mines, block gas flow channels, and increase coal gas permeability, etc. Freeze-thaw cracking effect, strong cracking pertinence, and the effect of increasing the freezing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

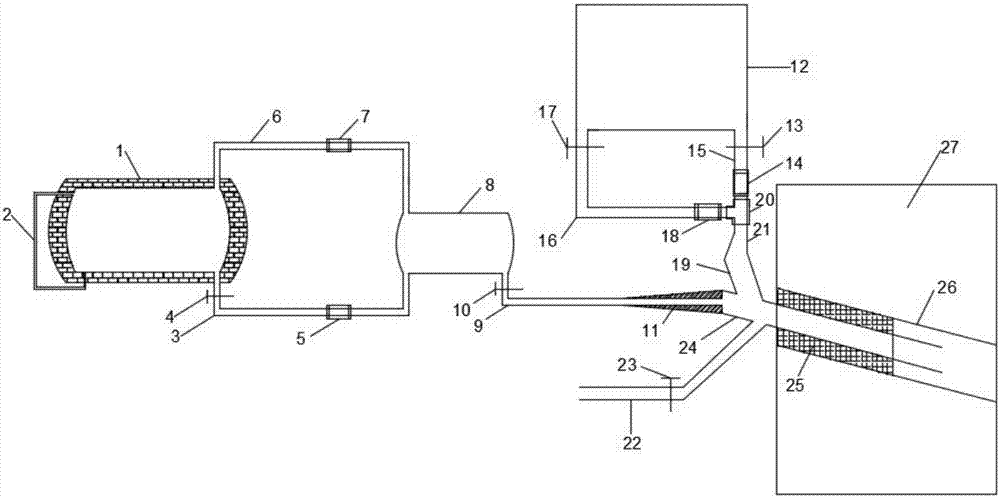

[0020] Such as figure 1 As shown, a method of injecting high-temperature nitrogen after the liquid nitrogen gasification cycle to increase the gas permeability of coal body, the nitrogen anti-permeability device used includes liquid nitrogen tank 1, liquid nitrogen amount observer 2, the first liquid nitrogen delivery insulation pipe 3, the second A nitrogen return pipe 6, a liquid nitrogen buffer tank 8, a second liquid nitrogen transport insulation pipe 9, a second control valve 10, a sealing pipe connection device 11, a nitrogen heating device 12, a third control valve 13, and a second nitrogen return pipe 15. High-temperature nitrogen injection pipe 16, fourth control valve 17, three-way valve 20, return port connection pipe 21, magnetized water injection pipe 22 and fifth control valve 23, and the liquid nitrogen volume observer 2 is fixed on the liquid nitrogen tank 1 , the outlet of the liquid nitrogen tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com