Air cylinder achieving gasoline engine compression ratio continuous variation and work method thereof

A compression ratio, gasoline engine technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve problems such as tight injector and spark plug positions, affecting gas combustion efficiency, and gasoline engine emissions. The compression ratio is continuously adjustable and the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

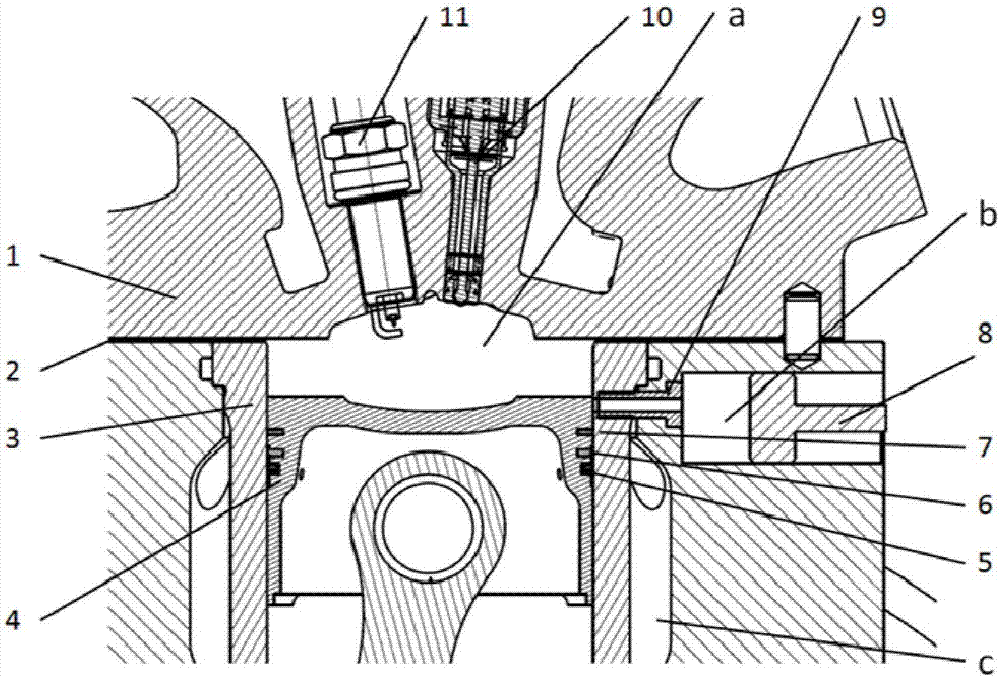

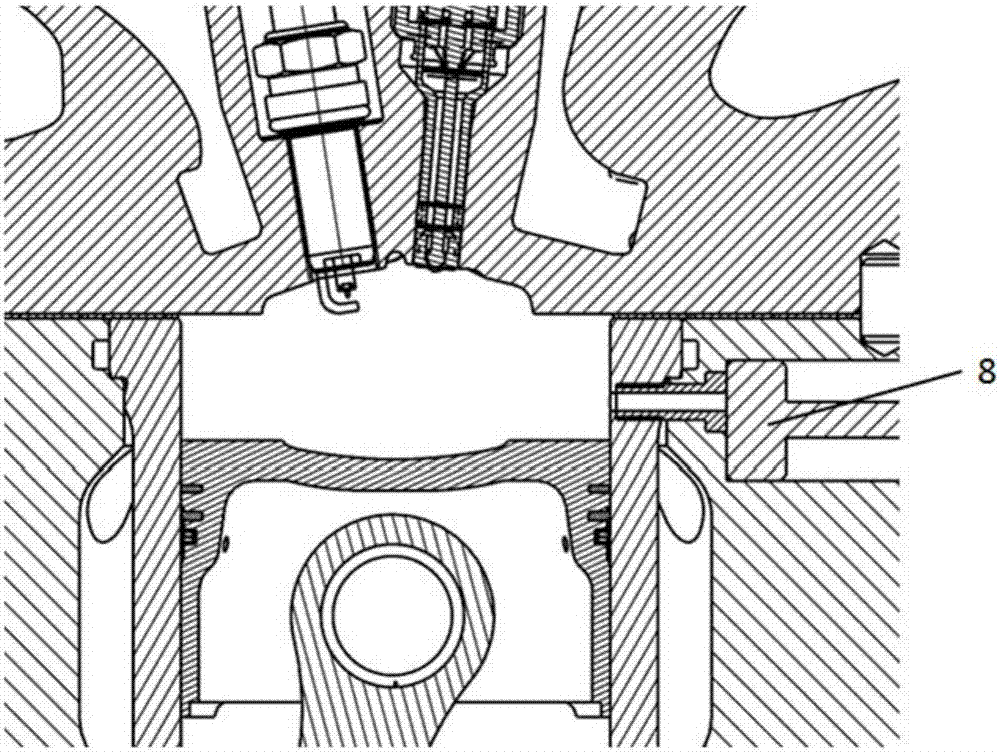

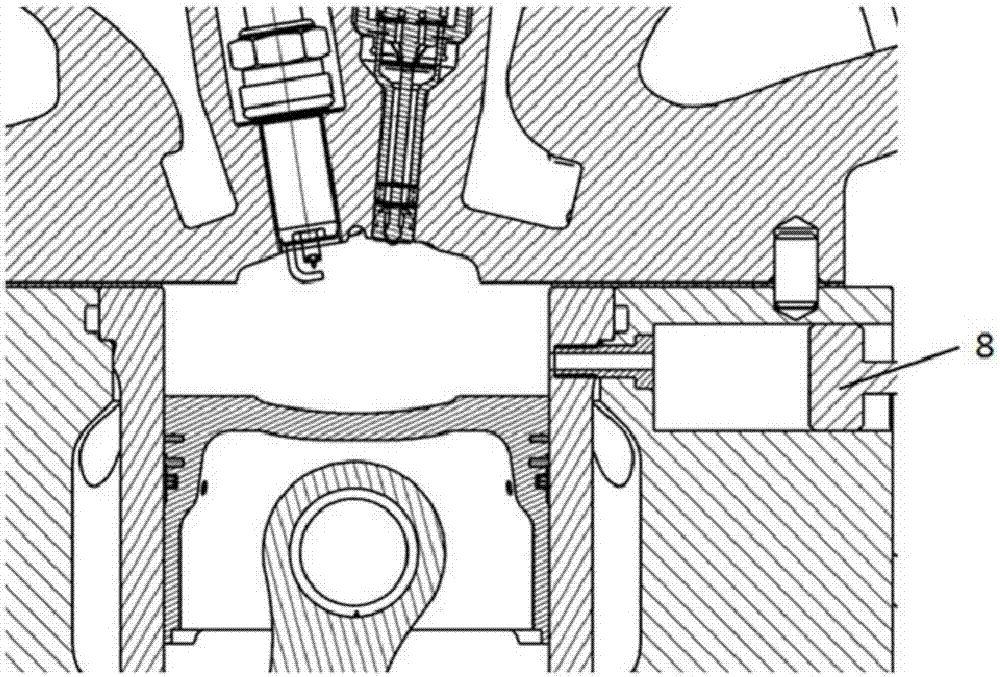

[0043] Such as figure 1 As shown, the system is mainly composed of cylinder head 1, cylinder gasket 2, cylinder liner 3, piston 4, oil ring 5, second air ring 6, first air ring 7, second piston 8, connecting pipe 9, oil injection Composed of device 10, spark plug and knock sensor 11, when the piston position is higher than the air hole of the connecting pipe 9, the cylinder is divided into the first chamber a that participates in combustion and the second chamber b that does not participate in combustion.

[0044] In the cylinder liner 3 or the upper half of the cylinder block, when the first piston 4 is at the top dead center, an air hole is opened in the circumferential direction between the top of the first piston 4 and the second air ring 6, so that the first chamber a and the second chamber The chamber b communicates, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com